Wire Hot Foil Printing Machine in Cable_Wire Marking and Printing Equipment

Wire Hot Foil Printing Machine in Cable_Wire Marking and Printing Equipment

Printing Principle of Various Printing Methods

Wire Hot Foil Printing Machine in Cable_Wire Marking and Printing

Cable_Wire Markings make identification and branding easy, but there are so many printing methods available that it can be difficult to determine which is best for your cable, wire application, there are several different factors that go into deciding which printing method will work best, we will go over each of them so that you can better choose between your options you must consider:

Jacket Material

Cable Diameter

Cable Surface Texture

Line Speed

Type of Message

Location of Printing

Industry Specification

Cost/Budget

Not all printing methods work well with all jacket materials, here is a list of which methods can be used with which materials

Hot Foil Printing: XLPE,PVC,PE, and PTFE, But not rubber

Laser Printing: PTFE and, PVC, but not untreated PE

Ink-Jet Printing: PVC Jackets, but not untreated XLPE or PE

Ink Wheels: Most Materials

Requesting printed samples is the best way to determine which method will be most effective, the cable and wire surface also has a major impact on which method works best, printing methods are categorized as contact or non-contact, contact printing works well with cables_wires that have smooth surface while non-contact printing works better for cables_wires that have uneven, rough, or convoluted surfaces, line speed comes into play for some industries more than others, the method that produces that highest print quality may not be the fastest, but for many industries, reducing set-up time by having easily legible print takes priority over reducing line speed, cost and industry standards are usually the most important factors, if a certain method of printing is widely accepted in your industry, it is often the method your should use, for example, building wire generally use ink-jet printing is common for small gauge wire, to choose which method is best for your cables_wires and application, consider the factors described above with the printing in-jet printing is a non-contact method of printing that makes the cables_wires using dots of ink

Advantages of Ink-Jet printing:

Most common method for cable manufacturers

Machinery is simple to program

High line speed

Disadvantage of ink-Jet Printing:

Certain chemical solvents and surface rubs can remove this type of print, but using pretreated wires and UV curable inks, or printing on warm cables can make the ink stick better

Ink-wheel printing: ink-wheel printing is a contact printing method that uses an engraved print wheel to transfer ink onto the cable surface, ink-wheels are also called gravure wheels

Advantages of ink-wheel printing:

Can be very durable so long as your choose the right ink

Highest line speed

Disadvantages of ink-wheel printing:

Print is fixed, so different wheels are needed for each print legend

Sequential marking is impossible with this method

Laser wire marker: Laser wire markers are used for non-contact printing, this method directs a laser at the cables_wires jacket, when the beam reacts with the particles on the cables_wires’ surface, it leaves a mark, different wavelengths of the laser produce different results and the color of the print depends on how the laser reacts with the cable jacket, PVC creates a light orange mark while other untreated materials show dark gray, this method is common in the military and aerospace industries

Advantages of laser wire markers

High quality printing

Creates a permanent mark, so long as the jacket material reacts with the beam

Software can be used to print graphic

Disadvantages of laser wire markers:

Slow line speed which may cause a back-up in production

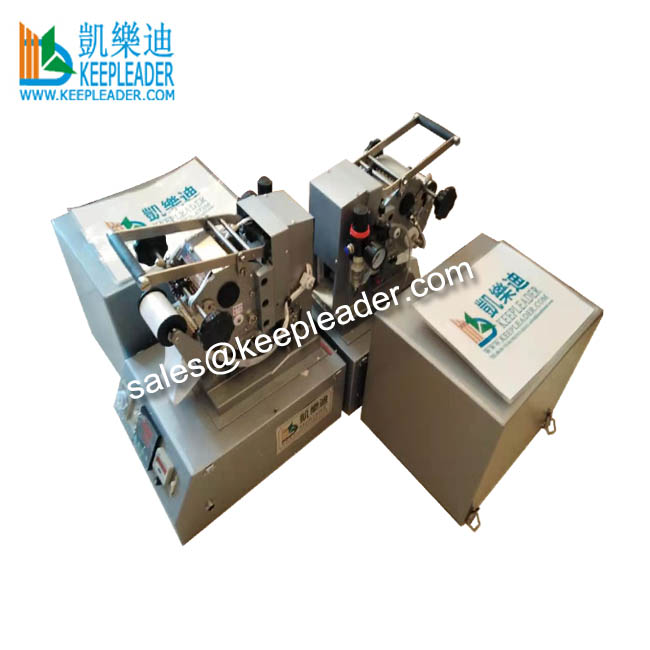

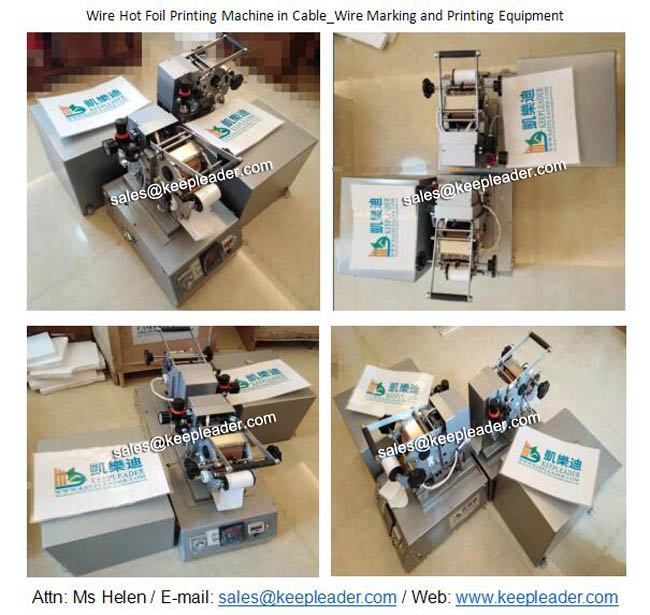

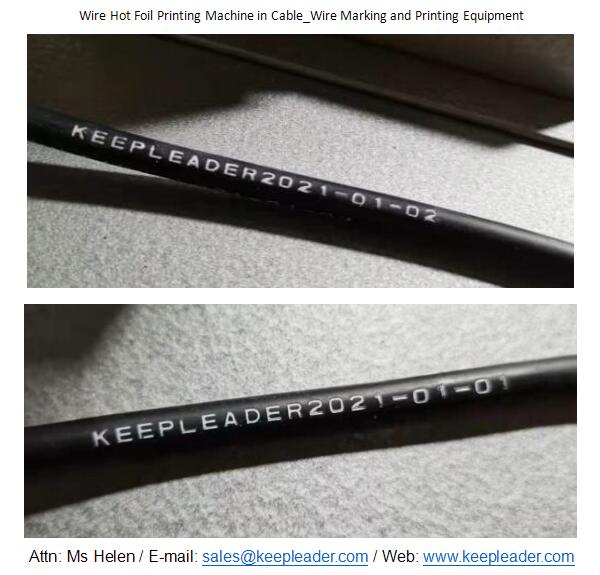

Wire Hot Foil Printing Machine in Cable_Wire Marking and Printing: This contact method of printing puts a permanent indent in the cables_wires jacket, stamping letters or numbers into the surface

Advantages of cable_wire hot foil printing:

Simple, low-maintenance process

Works with a wide range of jacket materials

Easily legible because it features an indent as well as color

Mark is durable even in harsh environments

Hot foil tape makes color changes easy

Disadvantages of cable_wire hot foil printing:

Does not work for thin-jacketed cable and wire as indent would damage the jacket

If the hot foil tape breaks, the print could be unclear

Code for the cable, wire must be set into print wheels manually

Indent and Emboss printing: indent printing is similar to hot foil printing in cable_wire marking, but without color, embossed printing is raised print on the outside of the jacket

Advantages of indent and emboss printing:

Creates permanent marks

Requires very little maintenance

Does not use ink or tape, so the cost of materials is reduced

Disadvantages of indent and emboss printing:

Printing is the same color as the jacket, so it may be harder to read each cable,wire printing and marking method has its own advantages and disadvantages, but now you should be better prepared to make an informed decision about which is best for you.

Details of Hot Foil Printing

Hot Foil Printing Uses

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader