Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine of Engine Block_Truck Part_Hardware Industrial Washing Ultrasound Bath

Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine

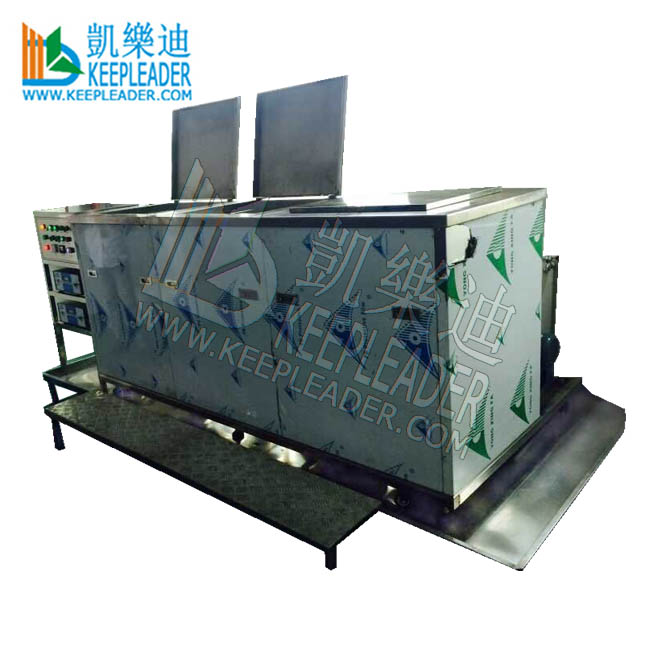

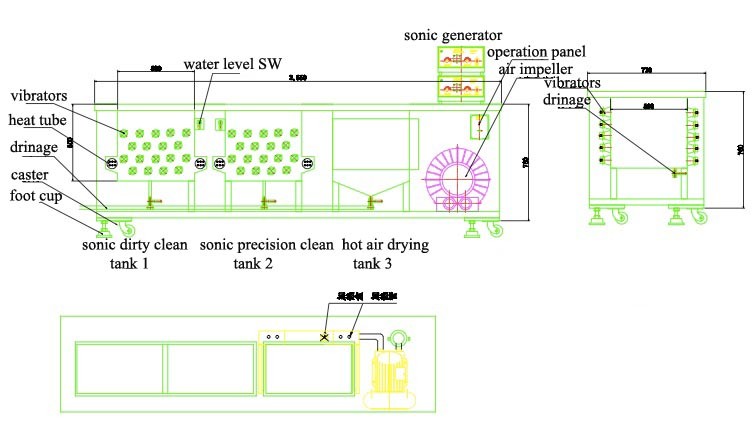

Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine has three tanks, the first tank is used for rough cleaning with ultrasonic agitation, the second tank is used for precision cleaning with ultrasonic aigtaion, the third tank is used for hot air drying, the cleaning tanks integrate filtering circulation reservoir, because of these combined functionality, this ultrasonic cleaner can effectively takes consistent cleaning performace, but keep the water consumtion at lowwest scale and avoid secondary contamination during the cleaning procedures

Product description

Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine

Application | |

Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine uses high-frequency sound waves to remove mold residues and mold fixture, the plastic mold or fixtures are immersed in a heated aqueous solution, an ultrasonic generator converts standard line-frequency current into high-frequency electrical energy, the ultrasonic generator is connected to small transducers vibrate at ultrasonic frequency when the current passes through, this causes the bottom or sides of the tank to vibrate like the diaphragm in a speaker, which scrub and loosen vent residues and grime | |

Character | |

KEEPLEADER™ is using full-bridge IGBT high-power integration modules-Germany Siemens to control power source, good protection against high temperature, high pressure and overheating, makes the cleaning effect perfect Withstand high temperature, it can reach up to 80 degree, Siemens modules is of high pressure resistance, as transistor and filed effect tube can be easily be broken down by correct under high voltage, not only affect the normal function but also disturbing the transducer’s frequency, Siemens can avoid this Siemens module control power is higher that other components, KEEPLEADER™ control circuit adopts the most advanced power adjustment according to different components Adopting originalGermanypiezoelectric ceramic chip, high-precision CNC machine equipment, and accurate test methods ensure KEEPLEADER™ high quality, and tank adopts exported 2mm SUS304 stainless steel Good appearance, low defective rate, easy operation and professional style | |

Parameter | |

Inner size of cleaning tank | 650*500*450mm |

Ultrasonic Vibrators | 48pcs |

Ultrasonic power | 2400w |

Heating power | 4kw |

Cycling and spraying tank | |

Inner size | 650*500*450mm |

Spray pressure | 10mpa |

Jet range | 100m |

Heating power | 2kw |

Hot air drying | |

Inner size | 650*500*450mm |

Heating power | 12kw |

Overall parameter | |

Power consumption | 21kw |

Power source | 380v / 50hz |

Outsize | 2400*1600*1400mm |

Net weight | 600kgs |

MFR: KEEPLEADER™ have modified and designed Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Detailed images

Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine has multiple tanks to achieve versatile cleaning procedures in rough cleaning, precision cleaning, rinsing, drying and filtering circulation and etc, becaue of pros and cons in each process, the designer often combine different mechanism to complete expected targets, this ultrasonic cleaning machine also can construct auto lifting and transferring system to auto feeding,loading and unloading among the cleaning steps

Buying guides

01: Choose your correct system

For customers demanding multiple stage ultrasonic cleaning and high efficiency parts drying, KEEPLEADER™ multi-stage consoles provide the same efficient, effective ultrasonic cleaning technology plus the ability to move the items items through additional wash and rise stages, KEEPLEADER™ will design a custom-sized and custom-featured ultrasonic cleaning machine to meet your specific needs

011: heated ultrasonic cleaning

012: heated ultrasonic cleaning + heated rinse

013: heated ultrasonic cleaning + heated ultrasonic rinsing

014: heated ultrasonic cleaning + heated ultrasonic rinsing + hot air drying

015: Inner size of cleaning tank, frame construction, custom color, ultrasonic frequency

02: Choose your tank size

021: the length*Width*depth you wanting

022: advise KEEPLEADER™ the size of your cleaning parts and cleaning efficiency

03: Each system includes:

031: Full insulated stainless steel tanks

032: Exterior power coat finish

033: Digital temperature controls-each tank

034: Digital timer-controlled ultrasonic cleaning

035: Dual stage filtration-cleaning stage

036: Single-stage filtration rinse stage

037: Low-level float sensors-each stage

04: Exceed industry standards

041: All size available, including bench version

042: High quality stainless steel construction

043: For vapor degreasing, cleaning and drying applications

044: Full solution control features

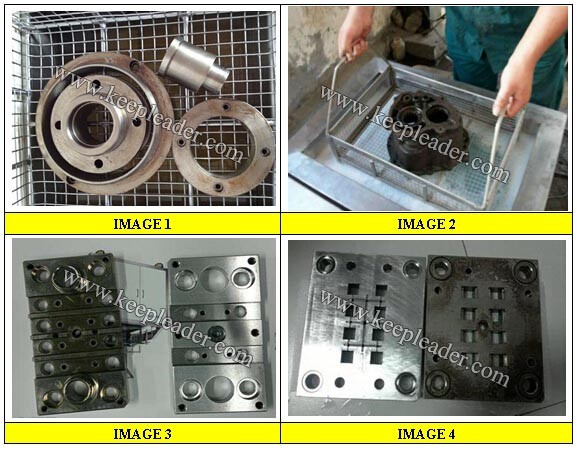

Product uses

Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine is reliable for cleaning process in car-truck parts, engine block_cylinder, machinery fixtures,tooling kits, hardware and other metal precision components

Function illustration

Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine has thress cleaning tanks of rough cleaning, precision cleaning and hot air drying, which also integrate filtering circulation, all functionality in one machine to achieve prominent performance in removing contamination

After-sales service

After purchasing at KEEPLEADER™ is first step of our after-service, all of machines at KEEPLEADER™ has one year guarantee, we provide free samples for defected parts to do replacement except for human damage, under information for your notice

01: KEEPLEADER™ always posts the new technical file in our homepage that can help our client in new technical information of machines’ design, character, application, operation, maintenance,

and related, KEEPLEADER™ also welcome our clients feed back the machines’ working condition that can get one to one service

02: If the machine you purchased has any defects, please contact sales representative at KEEPLEADER™, we will assign our experienced engineer analyze your case and provide technical support, in case of damaged parts that cannot repair, KEEPLEADER™ will provide a new parts to replace the defect

03: For any replacement and maintenance, KEEPLEADER™ has user manual and training video

04: KEEPLEADER™ can go to oversea for on-site training

05: KEEPLEADER™ can provide electric diagram if in need

06: Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine has instructional manual and training video and life-long tech assistance in operation, maintenance and trouble-shooting

Contact Us

Three Tanks Filtering Cleaner Ultrasonic Cleaning Machine is multiple tanks industrial cleaning with customized functionality and dimension, we'd like to provide professional service and exert double win cooperation, every concerns from our clients are sincerely considerate with details orientation achievement, please let us know more upon your application and expection to work out a reliable and affordble solution

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader