Ultrasonic vapor cleaning machine For Oil Parts Steam Cleaning Ultrasonic Vapor Degreasing Cleaner of Ultrasonic Vapor Degreaser

Ultrasonic vapor cleaning machine

Ultrasonic vapor cleaning machine is compacted structure of all functional process in one tank (Ultrasonic vibration scrubbing, vapor cleaning, condensation drying, and filtering circulation)

Product description

Ultrasonic vapor cleaning machine

01: Equipment introduction

KLE-1030R single tank ultrasonic vapor cleaning machine, using today’s most advanced ultrasonic technology with high “Q” transducer and world famous brand electronics, reasonable design, reliable and high efficient performance, have character of quick drying after cleaning, coupled with suitable cleaning basket, can achieve the optimal cleaning effect, ultrasonic vapor cleaning machine is widely used in cleaning of precision metal parts, electronic parts and etc heavy oiled parts

KLE-1030R single tank ultrasonic vapor cleaning machine is consisted by ultrasonic generators (power box), transducers, condenser system, liquid level controlling system and etc, ultrasonic generator produce electromagnetic signal, generate over 20khz ultrasonic electric signal and transfer to ultrasonic vibrators, ultrasonic vibrators convert the electromagnetic signal to mechanical vibrating, that’s to say an energy into another energy, the cleaning tank is loaded cleaning solution and cleaning parts, the refrigeration system produce cold air into condenser tube mounted at the top of cleaning tank to prevent the solution volatilization, and solution vapor is freeze by powered condenser tube, in this area, the solution vapor is transferred into liquid in recovering, in addition, the cleaning parts are quickly dried in cooling environment

02: Cleaning parts: precision metal parts, electronic parts and etc

03: Cleaning solution: trichloroethylene, trichloroethane and other non-flammable organic solvents

04: Cleaning process: ultrasonic cleaning→freeze dry→solution recovery

05: Machine parameter

051:ultrasonic cleaning tank (low half)

Tank structure | Inside size | 600*480*400(mm) |

Material | SUS316 Stainless steel, thickness: 2.0mm t, vibrating side is 2.5mm, and chrome plated | |

Structure | Have 1"drainage, slag hole | |

Ultrasonic system | Vibrating | The vibrators mounted at the bottom |

30pcs vibrators, have total power 1.5kw, its frequency 28khz. | ||

Adopted Japan “NTK “ vibrators, and advanced bounding technology | ||

Ultrasonic generator | External power box, frequency auto-sweep, digital display, the power intensity is optional, adopt 1GBT big powered power board to impel the strong output and stable performance | |

Heating system | Heating board | 2kw heating |

Temp control | Automatic temperature controlling system, RT-110 degree optional |

052: ultrasonic cleaning tank (top half)

0521: top cleaning tank

Tank structure | Inside size | *680*560*350mm |

Material | SUS316 stainless steel,thickness: 2.0mm. |

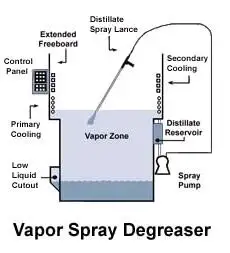

0522: Air-conditioning system

Structure | Cleaning tank top equipped with condenser tube, made of stainless stele 316, thickness 2.0mm, the top cooling is powered by air-conditioning unit, the tank lower 2-3/4 is cooled by external water |

Air-conditioning unit | Air compressor, power: 3HP. |

0523.Water separator

Circular route | The upping vapor is held down by condenser tube and coagulate to form liquid into the water separator, the dirty is drained out directly, and cleaned liquid or recovered solution and water into the tank |

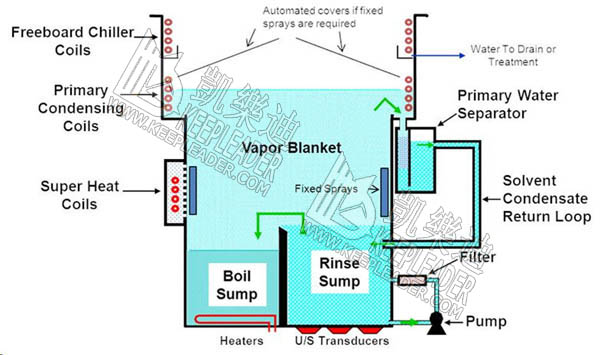

0524.Electric system

Structure | The power box mounted at the top side of machine, consisted by relay, circuit board, AC contact and overload protector and operation panel. |

Electronics | The electronics are make of Japan, USA famous brand |

0525.Spare parts

Auxiliary | Cleaning basket | 1ps, made of stainless steel |

Tank lid | 1ps, made of stainless steel | |

Support frame | 1ps, made of stainless steel |

06: machine overall parameter

Overall size | 840×720×1000(mm) |

Main power | 17KW |

Power supply | 380VAC,50Hz, 3 phase, 5pcs wires |

MFR: KEEPLEADER™ have modified and designed Ultrasonic vapor cleaning machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

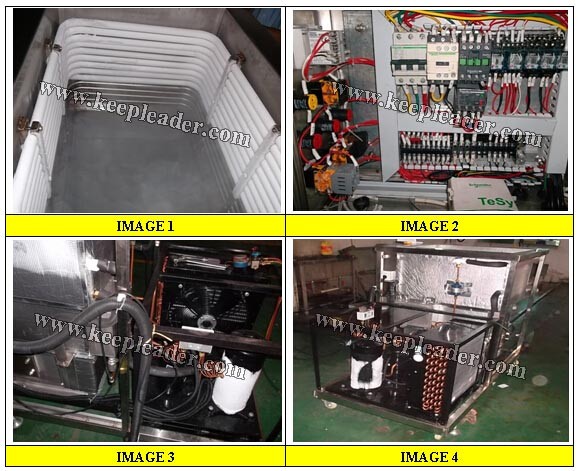

Detailed images

Ultrasonic vapor cleaning machine is manual loading, and Semi-enclosed structure of all in one tank vapor degreasing process with ultrasonic vibration scrubbing cleaning machine

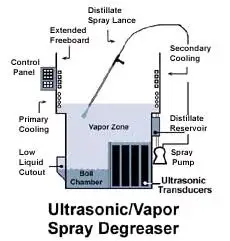

Function illustration

Ultrasonic vapor cleaning machine is universal model with these illustrated configuration, which ais also acceptable for customized combination or amendment for your cleaning

Packaging and shipment

Ultrasonic vapor cleaning machine is installed, packed in plywood case for safe transportation

Buying guides

Ultrasonic vapor cleaning machine

KEEPLEADER designed and built ultrasonic solvent vapor degreaser years of trouble-free operation, our machine is configured to operate with Chlorinated solvent to remove heavy grease, oils and compounds from heavily soiled industrial parts, or with the new ultrasonic, spray cleaning bends uses in precision cleaning applications, solvent cleaning must meet recent safe guidelines and include innovative features, like sealing covers, automated shut-down cycle, and early malfunction detection, all designed to make operating with the new solvent cost-effective and trouble-free

01: How ultrasonic vapor solvent degreaser work?

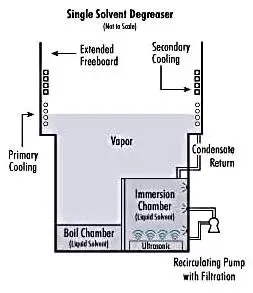

Solvent degreaser involves the exposure of cleaning parts to pure solvent vapors released by a boiling solvent, the cleaning parts usually suspended in the vapor zone above the boiling sump, when the vapor touch the comparatively cool cleaning parts, condensing action occurs which dissolves the contamination and flushes it away. And dripping into the boiling sump, because the boiling temperature of solvent is fixed, so the cleaning parts always touched the clean solvent, until the temperature of vapor is the same as cleaning parts, the cleaning action is stopped, this is basic cleaning schedules, the solvent cleaning machine often equipped with spraying cleaning, ultrasonic agitation, is usually used chlorinated solvents and new fluorinated solvent and other zoetrope

02: What’s application of the ultrasonic solvent degreaser?

Although water-based cleaning machine are effective in many applications, some aspects of aqueous-based cleaning can make it impractical and unusable for certain cleaning application, So, solvent cleaning comes into the practice by its special performance, which can well clean petroleum basked oil, grease, wax and other stubborn solvent soluble soil from any non-porous surface, solvent cleaning is also very useful at precision, it is also very effective at precision-cleaning highly sensitive parts contaminated with dust, fingerprints, and other air-borne contaminants, vapor degreaser is commonly used to clean, machine parts, electrical and electronic subassemblies, intricate metal and plastic components, artificial joints, lenses, and a wide variety of other products prior to further processing, assembly, inspection, or packaging, nearly any part can be cleaned in a solvent degreaser without concern for quality control issues like part oxidation, effective drying and water spots

03: Safety controls and Solvent detention system

All of ultrasonic vapor degreaser must be designed with consideration of guidelines for safety and solvent detention

031: Safety controls

Each solvent degreaser, there is float switch to detect the chemical level, if the safe level is not reached, the heating will be stopped, buzzer sounds up and inducting light is lighted to remind the operators to fill the solvent, the machine is also equipped with circuit protection of overheating, compressor fault and other automated controlling for safety purpose

Solvent retention systems

The most importance of solvent degreaser is the detention design of solvent efficiency, tries to reduce the leakage of solvent, and recycling the dirty solvent, is not only a safe principle but also the environment orientation, several factors involved in overall efficiency of the solvent degreaser

032: The primary cooling coils

A multiple pass perimeter cooling coil is used as heat exchanger to condense the vapors, creating a sustainable vapor zone, the primary coil must be maintained at the temperature that will cause the vapors to readily condense, this function can be performed by directly refrigerating the coil, or by passing chilled water through it

On refrigerated system: multiple condensing coils mounted perimeters above the primary coils directly, which is continuously detained the vapors to avoid the leakage and quick drying

On water-cooled system: water-cooled vapor degreasers, a coolant flows through the primary cooling coil, if a constant supply of cool water is available, the system can operate a water along, more commonly however, to save water and to assure constant temperature, a combination of coolant and water is circulated through a refrigerated water chiller, the water chiller may be dedicated entirely to one degreaser, or it many be serving the cooling requirements of other equipment simultaneously, water-cooled degreaser that are connected to a water chiller perform as efficiently as refrigerated system

033: Secondary cooling system:

The secondary cooling system consists of an additional cooling coil that is mounted directly above the primary cooling coil and maintained at sub-zero temperatures, creating a cold blanket of air, which further reduces solvent consumption, the safety guidelines call for freeboard chiller on vapor degreasers containing trichloroethylene, perchloroethylene, give that a properly-designed freeboard chiller will reduce evaporative losses by 30% to 45%, the cost of a freeboard chiller can easily be justified as a solvent-saving measure with a short payback period

034: Freeboard ratio

Freeboard is the area within tank above the vapor zone, the freeboard ratio compares the width of the top opening of the tank to the freeboard height, the height of the area above the top of vapor zone, higher freeboard ratios have been demonstrated to aid in solvent retention, freeboard rations between 1.25 to 1 and 1.5 to 1 are offered

035: Automated slide cover

Unlike common sliding cover that leave gaps around their perimeter, this unique cover is designed to roll into place and seal the work chamber from the atmosphere, virtually eliminating evaporative losses during downtime

04: Vapor spray degreaser

Ultrasonic solvent degreaser of spraying at KEEPLEADER has one compartment cleaning system, with the vapor zone located directly above the boiling solvent, this unit is designed for cleaning application that require suspension in pure solvent vapors only, typically, the cleaning parts are lowered into the vapor zone and held there until condensation ceases, if necessary, it is then sprayed with freshly distilled solvent to remove oil, chips, solder flux or other soils, spraying the cleaning parts also cools it slightly, causing the vapor to begin condensing on the cleaning parts again, once condensation ceases again, as the cleaning parts are then raised into the freeboard area where it is held until it is dry

05: Immersion/vapor spray degreaser

Parts contaminated with particular stubborn soils or very high-weight parts that reach the vapor very quickly may not be completely cleaned in the initial vapor stage when a vapor immersion is not adequate for a particular cleaning application, an immersion/vapor spray design is suggested, the cleaning circle of the immersion vapor spray unit is similar to that of vapor spray unit, except that after the vapor stage, the part is immersed in the warm liquid solvent sump, this step provide additional cleaning and also lowers the temperature of the cleaning parts, after the liquid immersion stage, the cleaning parts are then raised back into the vapor zone to allow for final vapor rinse prior to removal from degreaser

06: ultrasonic immersion/vapor spray degreaser

Ultrasonic degreasing offers advantages for the most stubborn contaminants and is commonly used for cleaning application like those listed below

Stubborn organic soils such as mold release agents wax and impregnated grease

Excessive particulate contamination on the cleaning parts

Inaccessible surfaces, blind holes and intricate passageways on the cleaning parts

Critical cleaning of high-reliability components such as printed circuit boards and hybrid/microcircuits

The ultrasonic vapor degreaser incorporates the same features as the immersion/vapor spray degreaser with the addition of ultrasonic agitation in the liquid rinse sump, the cleaning cycle remains the same, with the cleaning parts being suspended in the ultrasonic sump for the required time

07: Co-solvent degreaser

Co-solvent degrease sometimes called dual solvent degreaser, operate somewhat different the use unique combination of two distinct types of non-ozone depleting cleaning agents

Operate somewhat differently, they use a unique distinct types of non-ozone depleting cleaning agents, this system is sometimes used for flux removal, and is most appropriate for applications where pure fluorinated solvents or their zoetrope are not aggressive enough to dissolve the contaminant, the cleaning process is similar to single-solvent degreasing, except that in the initial cleaning stage, the cleaning parts are completely immersed in the wash compartment, a solvating agent in the wash sump dissolves contaminants from the cleaning parts, the liquid in the wash sump is constantly filtered to remove any sold particulate, the parts are then removed from the wash chamber and immersed in the rinse compartment, which contains pure liquid solvent, it is then raised in the vapor zone, where it receives a final vapor rinse, ultrasonic many be provided in either or both compartments, depending on the cleaning application, additionally, the solvating agent can be specifically formulated for the contaminant being removed and the ration of solvating agent to fluorinated solvent can be adjusted to affect the temperature and effectiveness of the wash compartment, because the system uses two chemistries with different boiling temperatures, its operation tents to be somewhat more complicated that that of a single-solvent machine and it normally supplied with an upgraded control package

Contact Us

Ultrasonic vapor cleaning machine is customized vapor degreasing machine in oil removing process, which also can combine with other functional configuration for premium performance, please contact us to fine what can we do more for you

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader