Automatic Ultrasonic Vapor Degreaser of Industrial Oil Degreasing Vapor Cleaning Machine for PCB_Plastic_Glass_Metal Steam Clean

Automatic Ultrasonic Vapor Degreaser

Automatic Ultrasonic Vapor Degreaser is #1:multipe-stage #2: Fully automatic process from loading to unloading #3: Solvent Steam Cleaning #4: Ultrasonic agitated in industrial Vapor Degreasing applied for PCB_Metal_Plastic oil and solid contamination diffusion and removing process

Product description

Application | |

Automatic Ultrasonic Vapor Degreaser is used for cleaning electronic components, the rosin of circuit board, heavy grease of precision mechanical parts, polishing wax, precision copper parts, aluminum zinc alloy, greasy hardware | |

Character | |

Imported vibrators IIE made in USA Stainless steel cleaning tank, SUS304,2.0mm for thickness Imported air cooling unit made in USA Other electronics, made in Japan or South Korea Build-in condensing system, fully enclosed, by which to avoid solvent evaporation Liquid level sensor and alarm system for ensuring the machine work properly Solvent filtration and recycling system reduce the production cost Fast drying system to improve efficiency Automatic temperature control system | |

Qualified Solvent | |

Trichloroethylene, methyl chloroform and other organic solvents (non-flammable solvent) | |

Cleaning process | |

First class ultrasonic cleaning→second class ultrasonic cleaning→vapor cleaning→cooling and drying (automatic distillation solvent recovery and automatic recycling) | |

Mainly Parameter | |

Ultrasonic cleaning tank ( fist class and second class) | |

Model | KLE-4036RA |

inner cleaning tank | 410*420*470mm(L*W*H) |

Vibration mode | Bottom |

Vibrators number | 36pcs |

Ultrasonic power | 1800w |

Ultrasonic frequency | 28khz |

Heating power | 4kw |

Heating mode | Heating board from outside |

Temperature | 0 up 100 |

Vapor cleaning tank | |

Inner cleaning tank | 410*420*480mm(L*W*H) |

Heating power | 4kw |

Heating mode | Heating tube into the water |

Temperature | 0 up 110 |

Distillation tank | |

Inner cleaning tank | 410*420*490mm(L*W*H) |

Heating power | 4kw |

Heating mode | Heating tube into the water |

Temperature | 0 up 110 |

Frozen system | |

power | 3HP |

Frozen height | 450mm |

Turns of frozen pipes | 10-3/4 |

General parameter | |

Overall size | 4040*1200*1900mm |

Overall power | 20kw |

Power supply | AC380V,50HZ |

MFR:KEEPLEADER™ have modified and designed Automatic Ultrasonic Vapor Degreaser for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Detailed iamges

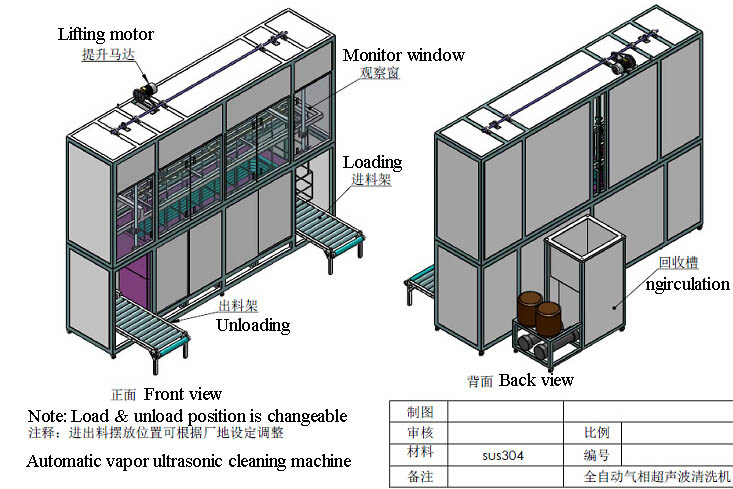

Automatic Ultrasonic Vapor Degreaser has built-in #1: Sevo driven transmission #3: Ultrasonic agitation #3: Reciprocating compressor #4: Distillation recirculation #5: Top Condensing Cooling Jacket #6: Programmable Logic Controller+Touch Screen #7: Safe Protective Sensor alarm #8: Ultrasonic cleaning-ultrasonic rinsing-vapor cleaning-distillation drying in-line process #9: Fully Closed Shield and Vapor emission impeding #10: Down aigitation and Slow lifting elevator #11: Pre-cleaning Tank combined

Function illustration

Automatic Ultrasonic Vapor Degreaser can accept individual configuration, size for exceptional application

Buying guides

01: Choose your correct system

For customers demanding multiple stage ultrasonic cleaning and high efficiency parts drying, KEEPLEADER™ multi-stage consoles provide the same efficient, effective ultrasonic cleaning technology plus the ability to move the items items through additional wash and rise stages, KEEPLEADER™ will design a custom-sized and custom-featured ultrasonic cleaning machine to meet your specific needs

011: heated ultrasonic cleaning

012: heated ultrasonic cleaning + heated rinse

013: heated ultrasonic cleaning + heated ultrasonic rinsing

014: heated ultrasonic cleaning + heated ultrasonic rinsing + hot air drying

015: Inner size of cleaning tank, frame construction, custom color, ultrasonic frequency

02: Choose your tank size

021: the length*Width*depth you wanting

022: advise KEEPLEADER™ the size of your cleaning parts and cleaning efficiency

03: Each system includes:

031: Full insulated stainless steel tanks

032: Exterior power coat finish

033: Digital temperature controls-each tank

034: Digital timer-controlled ultrasonic cleaning

035: Dual stage filtration-cleaning stage

036: Single-stage filtration rinse stage

037: Low-level float sensors-each stage

04: Exceed industry standards

041: All size available, including bench version

042: High quality stainless steel construction

043: For vapor degreasing, cleaning and drying applications

044: Full solution control features

Packaging and shipment

Automatic Ultrasonic Vapor Degreaser is installed in sea transportaion, we also provide tutorial video and installation, operation, maintenance instruction, or on-site training if so in need

Contact Us

If you have porous parts in precision cleaning, Automatic Ultrasonic Vapor Degreaser is the reliable solution for enviroment-friendly, cost-saved, consumtion-reduced, consistent cleaning effect, please contact us for your practical application, our tech team will work out our professional solution for your tech verification prior to your proper decision

☺ Attn: Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader