Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine for Canvas_Tarpaulin HF_RF Seam Fusing Equipment

Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine

Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine is alive seam sealing practice via high frequency welding,also known as radio frequency welding, HF/RF welding or dielectric welding, is the process of fusing fabrics together by applying a rapidly alternating electric field applied between two bar in the joint area, HF welding only works with thermoplastics that have a high dielectric constant, a factor determined by the molecule’s geometry and dipole moment

Product description

Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine

Mainly application | |

| Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine Applied for tarpaulin, sun shading canvas, sunblind, stretch ceiling, painting canvas, film curtain, canopy, Truck cover, car tent, Billboard, Canopy, awning and other around of this kind of membrane structure material welding or sealing | |

Character | |

High Q value oscillation tube the welding length is optional, maximum length:2000*25mm for 25kw The machine is G shape, have longer throat to hold the material High sensitive anti-sparkle device NL5557 to avoid damaging the mould. High quality imported apparatus European-model high frequency vibration box, more reliable and stable in output Laser position device for precision counterpoint Have boosting roller at two side for easy feeding materail Mounted five caster with four brakes Automatic thermostat to keep the temperature at best performance in welding High precision high frequency knob for visible control Low voltage control panel for safty purpose Anodized mould and tooling for longer life-span Top amounted cylinder for vertical pressing, which is more uniform pressure Foot pedal control and button control is optional Over current protection circuit to avoid burning the oscillation tube Power ranges 4kw up to 25kw for various welding length | |

Technique specifications | |

| Model | KLR-10KW-MN |

| Power | 10KW |

| Power supply | 220V/380V 50/60HZ |

| Frequency | 27.12MHZ |

| Input power | 18KVA |

| Rectifier | SILICON DIODE |

| Oscillation tube | E3069 |

| Max pressure | 800kg |

| Gap of electrodes | 100MM |

| Moving distance of active horn | 100MM |

| Size of upper electrode | 900*25MM |

| Size of down electrode | 1200*300MM |

| Welding time | 0~10S Adjustable |

| Net weight | 800kg |

| Overall dimension | 1650*1350*1740 |

Standard equipment:

Name | Origin |

Air driven components | Taiwan |

AC contactor | Korean |

Relay | Japan |

Electron Tube | Japan |

Time controller | Taiwan |

KEEPLEADER has modified and designed Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine to accommodate our customers' unique and special requirements,

pls contact KEEPLEADER for tech assessment with your detailed app.

Detailed Images

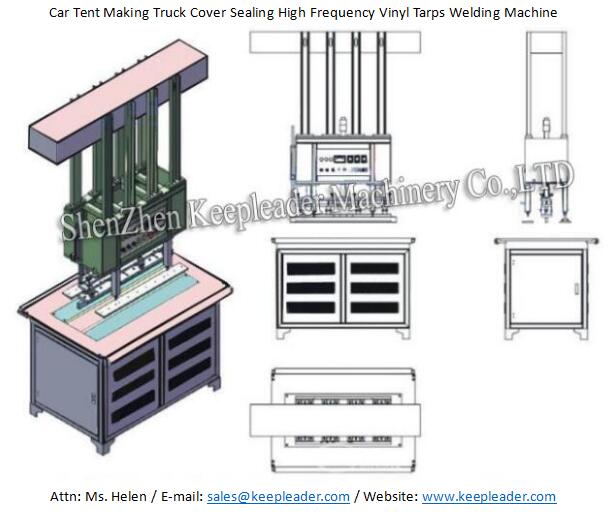

Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine is composed by HF generator, suspended welding head, and working table, HF generator transmit electrical current to high frequency alternating current of 27.12 megahertz, the polymer’s dipole molecules attempt to flip around to realign themselves to the new field orientation, this high-speed, relative movement causes inter-molecular friction, which creates heat, when the polymer reaches its glass transition temperature (melts), the pressure is applied at the joint by the high frequency electrode/bar until the fabric cools, during this process, the molecules from both fabrics intermingle and weld forms, the resulting weld can be as strong as the original fabric, molecules of fabric with low dielectric constant do not flip quickly or at all, consequently, they will not generate the required heat to form a weld, because of suspended/hanging welding head which avoid pneumatic driven standing frame to exert pressure during bonding to save the footprint, also is convenient to align the welding position at any direction

Machine Uses

Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine is dielectric bar welder in molecular scaled seam sealing at the localized overload jointing interface, high frequency oscillation energy causes the temperature raised because of polymer resin molecular realignment in molecular movement under controlled pressure, when the High frequency halts, the melted thermal plastic takes quickly bonding after solidification, the welding principle of high fequency tech is definitely different with the conversional heat sealing process, the heat comes from interior to achieve a integrated sealing, the welding area is stronger that the material matrix, particularly, its bonding can bear the tearing and peeling force

Overall Illustration

Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine exerts seam bonding process of instantly heating, melting, cooling in membrane structure construction, because of it creates air and liquid leak proof seals, tear and tear resistance with near-invisible seams, no wicking edges, and bonds that are as strong or stronger that the original fabric itself, the weldable material is polymer, which has high scale of dielectric constant, likely PVC, PU, TPU, EVA, ABS resin, PETG and APET

Contact Us

Car Tent Making Truck Cover Sealing High Frequency Vinyl Tarps Welding Machine is acceptable in construction of size, function, color, shielding. controlling system and auxiliary, we intend to provide a reliable and affordable seam joint bonding solution basing on robust structure, consistent and strong bonding strength, convenient operation, and precision control, if you cannot find your concerns, just share your proposals with our technical teams or sales representatives, our experts are always ready to work with together, submit their experienced suggestion for your approval after comparison prior to execution

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader