Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine of PVC Canvas_Tent_Truck Cover_Awning H/RF Sealing Equipment

Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine

Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine is also called dielectric welding, they have the same bonding technique, radio frequency energy is directed through electrodes custom-build to the required shaped usually through the user of a tool, this make RF sealing the most versatile of the polymer film sealing method, RF sealing uses a precise combination of tile, pressure, and RF wave to form a stronger, more uniform weld that is possible using other methods, this “G” shaped Radio frequency bar welder is professional constructed for linear seam sealing in flexible products making, such as sun shading, billboard, truck covering, oil booms, water cistern/tank and other relative production, that are typically made of PVC and PU with prominent weld-ability

Product description

Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine | ||

Mainly application | ||

Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine is used for large format structural membranes, pool-liners, oil-booms, water cisterns, tarpaulin, tents, tensile structures, advertising billboards, spark protection cloth, tent of truck, canvas of agricultural, canopy, swimming pool covers and other PVC/PU technical textiles, large PVC canvas/digesters/ fabric, computer advertising / printing/ Film cloth, the membrane structure, etc. | ||

General Features | ||

length, width, curve of welding electrode is optional and adjustable square high frequency vibration box, more reliable and stable in output Single line or two lines continue welding, welding length can be customized CE rated machine; factory verified by SGS Customer's site installation, training & maintenance available pedal valve control in double side for easy operation Customized work table dimensions, electrode holder dimensions, tooling with laser light to make precision position Servo-motor; Touch screen programmable HMI / PLC HF Filter unit available Groove length is up to 1.5m, welding length is up to 50mm | ||

Parameter | ||

Model | KLR-15KW-LN | KLR-25KW-LN |

Output Power | 15000W | 25000W |

Anti-Spark | U.S.A. PL-5557 High sensitive anti-spark system | |

Voltage | 3P AC 380V 50Hz-60HZ or customize | |

Frequency | 13.56MHz+/- 0,6 % | |

Input power | 15KVA | 35KVA |

Rectifier | SILICON DIODE | |

Oscillation tube | 8T85RB | 8T25RA |

Max pressure | 1000kg | 1500kg |

Operation mode | Pneumatic Operated | |

Max gap of electrodes | 100mm | |

Size of active horn | 100mm | |

Upper Electrode | 200*1300mm | 200*1500mm |

Size of Work Table | 200*1350mm | 200*1550mm |

Welding time | 0.01~9.99s adjustable | |

Net weight | 1500kgs | 1400kgs |

Net length | 1500mm | |

MFR: KEEPLEADER™ have modified and designed Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

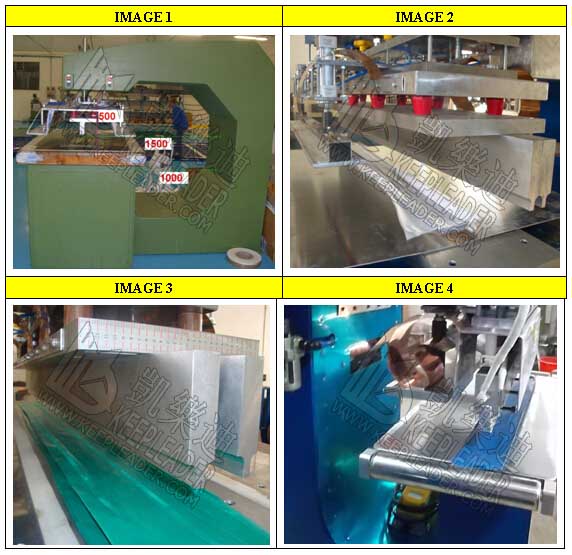

Detailed iamges

Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine is prevalent welding technique in flexible product making, the radio frequency bar welder generates radio waves that create heat inside the tarpaulin/canvas via molecular action, the molecules that comprise the plastic are essentially flipped from a positive to negative electrical charge at a rate of several thousand times per second, this process generates friction from inside of fabric that is transmitted to the outside, the combination of heat produced by the friction and the pressure applied by the bar dies creates a seal that bonds the tarpaulin/canvas layers together, Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine is often used to produce truck tarp seams, the radio frequency bar welder seals the tarp’s fabric panels together in much the same fashion as a sewn seam

OEM Service

Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine works typically through five steps process,1st:loading parts: joint member is placed into the welding machine to undergo RF Heat sealing;2nd:pressure application: pressure is applied to the joint member through electrode, pressure describes force applied to an area and in this case a fixed electrode at the bottom requires an actuator to drive the upper electrode bar downwards with the prescribed force;3rd:Electrical field application: at this point, an electrical field is applied for a designated amount of time while pressure is maintained throughout the process;4th: holding pressure: as pressure is continually applied along with the electrical field, the portion of the joint member directly in contact with the equipment will melt and liquid polymers will diffuse into each other at the respective points of contact;5th:unloading parts/cooling: this process engages through a chemical process of diffusion and solidification to weld the members together, as this point, after the joint cools down, the upper electrode is now brought back and parts are unloaded

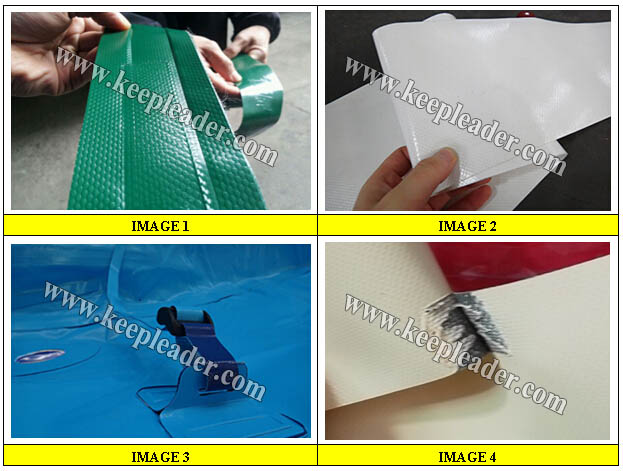

Welding effect

Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine applies for broad spectrum of products that are manufactured with radio frequency wave energy, such as tensile structure, tents, swimming pool, liners, high-speed rolling doors, oil booms, billboards, awning, truck covers, membrane curtains, swimming pool covers, temporary shelters, sunshades, army tents, structural membranes, pool-liners, water cisterns, TPU water tanks, canopy, painting canvas, canvas, inflatable products, and many more, this reflects the versatility and application of Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine across various industries

Contact Us

Keepleader, we can meet your Radio Frequency Bar Welder Tarpaulin High Frequency Welding Machine requirements whether you demand customized dimension or stipulated configurations, our tech team can create custom version to tackle your specific precision sealing needs, for more information, talk to our recipient, trust that we can work out a reliable solution at affordable price for you

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader