High Frequency Plastic Tents Welding Machine of Tarpaulin_Canvas_Marquee Awning Cover_PVC_PE Coated Fabric Stationary RF Welder

High Frequency Plastic Tents Welding Machine

High Frequency Plastic Tents Welding Machine is the stationary RF welder,which is the industry’s most versatile radio frequency welder available on the market, keepleader was designed for the production of tarpaulins, tents, truck tarps, high speed doors and any other flexible polyvinyl chloride (PVC) or Polyurethanes(PU) product, with enhanced features such as, a deep material-trough for better material handling, a infrared scanning system to line up the laminated layers in positioning process,your production will be even more efficient and reliable

Product description

Mainly application of Awning/tarpaulin/tent high frequency welding | |

High Frequency Plastic Tents Welding Machine applied for tarpaulin, sun shading canvas, painting canvas, film curtain, canopy,awing,truck cover, car tent,stretch ceiling, sunshades and other around of this kind of membrane structure material welding or sealing | |

Character of tarpaulin/TENT/Inflatable high frequency welding/welder | |

High Q value oscillation tube the welding length is optional, maximum length:2000*25mm for 25kw The machine is G shape, have longer throat to hold the material High sensitive anti-sparkle device NL5557 to avoid damaging the mould. High quality imported apparatus European-model high frequency vibration box, more reliable and stable in output Laser position device for precision counterpoint Have boosting roller at two side for easy feeding materail Mounted five caster with four brakes Automatic thermostat to keep the temperature at best performance in welding High precision high frequency knob for visible control Low voltage control panel for safty purpose Anodized mould and tooling for longer life-span Top amounted cylinder for vertical pressing, which is more uniform pressure Foot pedal control and button control is optional Over current protection circuit to avoid burning the oscillation tube Power ranges 4kw up to 25kw for various welding length | |

Technique specifications of tarpaulin high frequency welding | |

Model | KLR-10KW-SN/KLR-12KW-SN |

Power | 10kW/12KW |

Power supply | 220V/380V 50/60HZ |

Frequency | 27.12MHZ |

Input power | 20KVA |

Rectifier | SILICON DIODE |

Oscillation tube | E3069RB/E3130 |

Max pressure | 600kg/800kg |

Gap of electrodes | 120MM |

Moving distance of active horn | 100MM |

Size of upper electrode | 100*1000MM/100*1400MM |

Size of down electrode | 120*1200MM/120*1400MM |

Welding time | 0~10S Adjustable |

Net weight | 800KG/900KG |

Overall dimension | Customized |

Name | Origin | Brand |

Air driven components | Taiwan | Airtac |

AC contactor | Korean | LG |

Relay | Japan | Omron |

Electron Tube | Japan | Toshiba/Jingguang |

Time controller | Taiwan | CKC |

please contact KEEPLEADER™ for more information and technical assistance

Note:

Please tell us following information intended for High Frequency Plastic Tents Welding Machine:

❶ The material and definite size of the product;

❷ The maximum welding length in maximum

❸ The features you preferred on this machine

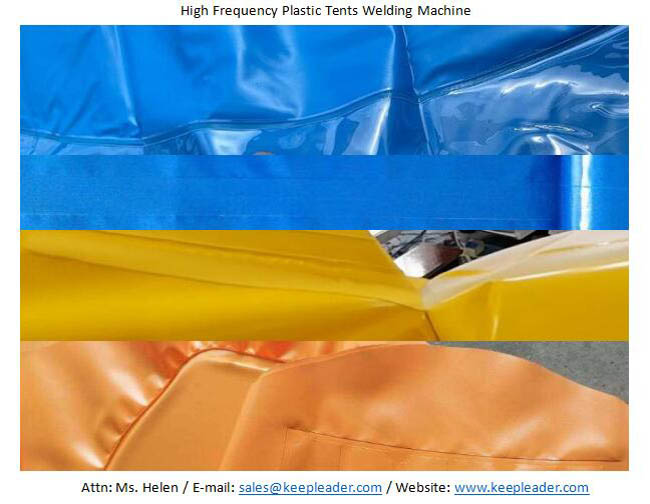

Detailed Images

High Frequency Plastic Tents Welding Machine has salient features in #1: H.F power output from 5kw to 25kw #2:each material positioning with deep trough behind electrode #3: Infrared light guide projectors to assist on positioning process #4: angular and special shaped upper electrode is available #5:built-in smooth glide wheels for easy movement in-around welded fabric, or relocation to a desired place

Product uses

High Frequency Plastic Tents Welding Machine has versatile applications in field of #1: small and large format technical textiles PVC or PU coated fabric #2: tensile structures, tents, shade systems, truck covers and side curtains #3: swimming pool liners and covers, flood dams and water tanks #4:airport hangars,portable storage structures #5:containment pools, oil booms and ground liners #6: advertising signs and large format billboards

Contact Us

High Frequency Plastic Tents Welding Machine is processes that have long been used to create high integrity seams on a variety of flexible products, although the sealing processes are different in execution, they have relatively the same result, the bonding of polymer films on a molecular level, but, the custom-built interchangeable electrode bar or platen is necessary for different processes in size, shape, profile and pattern, it isn’t avoidable to examine your application prior to offer, our sales are always ready for listening and working with you to produce a affordable, reliable dielectric welding solution

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader