Double Head Ultrasonic Welder Plastic Welding Machine for Air Humidifier_Car Lamp Making ABS_PP_PC Shell Sonic Sealing Equipment

Double Head Ultrasonic Welder Plastic Welding Machine

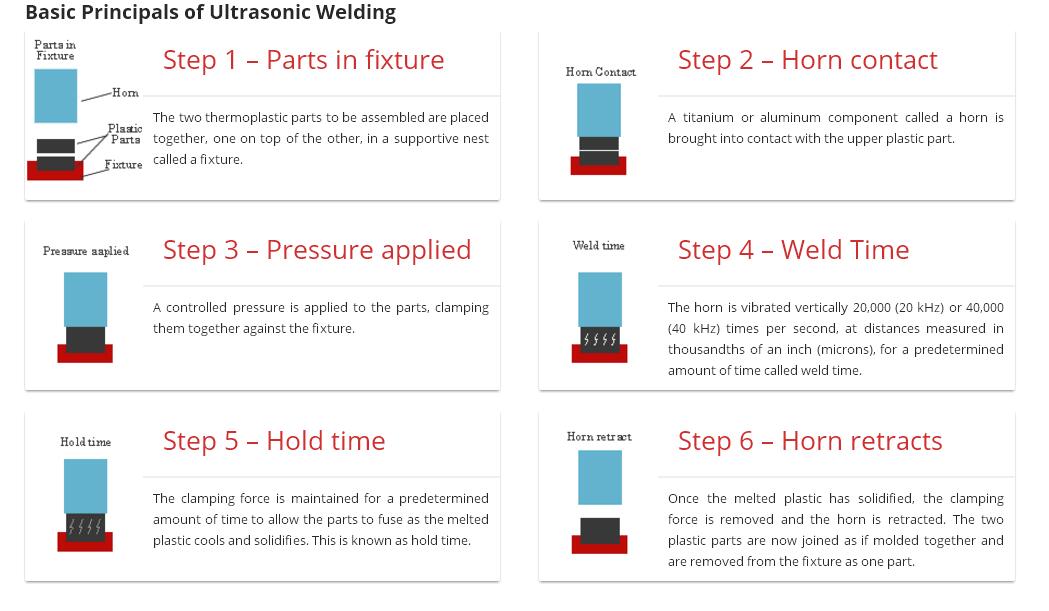

Double Head Ultrasonic Welder Plastic Welding Machine is a welding thermoplastic bonding in humidifier making that utilizes mechanical vibrations above the audible range, the process is accomplished by converting high frequency electrical energy to high mechanical motion, the mechanical motions applied along with force generate frictional heat at the joining interface of humidifier hell, this causes the energy director built in the joints of hell halves to met and forming a molecular bond to integrate two halves of hell into one resulting in water-proof and air-tight, this technique is fast, economical, easy to automate and well suited shell’s made of PP,PC, ABS in mass production, moreover, the welded shell of humidifier is not only in a solid status bonding but also in a good appearance

Product description

Double Head Ultrasonic Welder Plastic Welding Machine

01: Parameter

Model | KLC-2615D |

Ultrasonic power | 5200w |

Ultrasonic frequency | 15khz |

Input power | 2.4kw |

Welding depth | 70mm |

Welding time | 0.1~99s |

Vibration system | Auto-stimulating |

Welding size | 400mm |

Power Supply | 220V/50hz |

Net weight | 220kgs |

02: Application

Ultrasonic welding of thermoplastic materials creates a molecular bond within the welding seam, longitudinal vibrations in frequencies of 15khz, 20khz and 35khz with tool amplitudes between 5um and 50um are introduced into the plastic materials under the action of force, ultrasonic vibrations are focused by means of special design of components of tools, this specific geometry within a component is referred to as energy director, the contact points in the joining area actively molded by means of energy input to achieve elastic deformation occurring between the contact surfaces and within the molecule chains generates heat that causes the materials to melt

03: Highlighting

High efficiency converter

Rigid frame construction

Pneumatic speed regulation

Frequency tuning with reading of idling and welding power on the instrument

Triple time for delay time, welding time and holding time

Welding pressure adjustable for 6 bar

Palm button or foot operated switch operation

Microprocessor based controller

Welding time, holding time settable in the steps of 100 milliseconds

Digital counter up to 100,000 counts-resettable

Digital bar graph to indicate tuning and energy during the welding cycle

Leveling screws provided on the ultrasonic assembly for each leveling and alignment

Of horn face with the welding object

Detailed Images

Double Head Ultrasonic Welder Plastic Welding Machine combines two sets of ultrasonic vibration system used for large size bonding of humidifier’s shell, high frequency ultrasonic acoustic vibrations are applied to the shell halves that are hold together under compression to create a solid state weld, ultrasonic welding is commonly used for thermoplastic jointing process, which perform a reliable bonding action in making humidifier, the welded shell, case, house take effect of water-proof and air-tight, there are no connective rivets,bolts, nails, soldering materials, or adhesives required to fix the shell halves together, moreover, the jointing interface has cosmetic appearance

Our service

01: A dedicated customer oriented performance

KEEPLEADER has stringent quality fist regulation, from beginning consultation to end after service, we try every efforts to provide our knowledge for everyone around, try our best to demonstrate our solution efficiently and effectively, out ultrasonic technology capabilities, dedicated specialists are available to perform trials with different equipment in order to propose you the best solution adapted to your specific product and need, don’t hesitate to send KEEPLEADER your products or to submit your request to our specialist or sales representatives

02: Strong sub-supplier relationship:

Our privileged relation with our cooperators allows us to work together and develop specific solutions, such as mechanical structure, for implementation on customized machine, our engineering department works regularly cooperation with our cooperator engineers to design adapted mechanical structure to your existing process line, and this characteristic relationship is the key to our success with OEM orders

03: Marvelous service

Our sales team is composed with market specialists, with specific knowledge of various business sectors to ensure the most appropriate answer to each customer’s specific need: quotation, sales administration, order follow-up and logistic and etc

Our after-sales department is dedicated to customer service: start up and commissioning of equipment worldwide, our engineers ensure start-up for an optimum production of our equipment, training of customer’s operators; our service proposes training of your operators to optimize your device use and increase your productivity, spare-parts, repairs and equipment performances evaluation to maintain and keep your investment up-to-date

Buying gides

Brief introduction

Ultrasonic welding is primarily used for thermoplastic joining, compared with other plastic welding techniques, plastic ultrasonic welding has the advantages of excellent welding quality, high production efficiency and wide application, the advantage of excellent welding are extensive and are found in many industries inclucing electronic and electrical, automatic and aerospace, civil engineering, medical and packaging field

KEEPLEADER™ can develop kinds of automatic ultrasonic welding production line to meet customers’ unique requirements, standard ultrasonic welding machine can be divided into table-type and cabinet-type, for cabinet-type, a delicate plastic welder to facilitate operation

Characters of ultrasonic welding machine at KEEPLEADER™

01: Suitable for welding, PP, PS, PE, PC, ABS, PBT and etc

02: No need any adhesive or flux and less heat consumption

03: Easy operation, high efficiency, excellent outward appearance, and high strength

04: AIRTAC pneumatic components durability

05: Automatic and manual operating mode, convenient for adjusting

06: CE, SGS international quality certificate

07: One year warranty

Service process at KEEPLEADER™

the clients offer information of the workpieces being welded (eg: picture, materials, sizes, requirements, etc) if have samples, it’s better to send KEEPLEADER™ some sample to perform the welding test, if can be welded, we provide offer sheet, once confirmed, sing a contract, the clients paid the deposit, KEEPLEADER™ start equipment building, after passing the acceptance, and receive the balance payment, KEEPLEADER™ delivery the device to clients

Some application examples:

Auto parts: bumpers, air filters, car audios, foot pads, door panels, clutch forks

Electric products: humidifiers, charges, storage battery, telephones, sockets, flash discs

Medical products: Leucocyte filters, accurate liquid medicine filters, blood plasma separating cups

Packaging and clothing: Valve bags, paper cups, dairy food packing cases, bag belts, zippers

Stationery and toys: ink boxes, file folders, name card holders, albums

FRQ

Application of turntable plastic ultrasonic welder at KEEPLEADER™

Field ranges: Automotive electronic, home appliance, industrial components, electrical wiring components, lighters, toys, gadgets, medical, personal appliances and related

For example; Suitable material: It is widely used in welding ABS, PE, PS, PVC, PP, ABS and PC synthetic, Acryl, etc, KEEPLEADER™ can do customized design and modified machine to accommodate our clients’ unique and special requirements

Plastic parts of automobile body: Car door, automobile instrument, car light and mirror, sun visor, interior trim parts, filter, etc, reflectorized material, reflectorized spike, fender-guard, inhaul cable, plastic filter for motorcycle, radiator, oil reservoir, oil cup, water tank, fuel tank, air hose, exhaust purifier, and tray filter board, etc.

Plastic electron: prepayment water meter, ammeter, communication apparatus, cordless telephone, accessories of mobile phone, cover of mobile phone, battery case, charger, valve controlled seal maintenance lead-add battery, 3-inch floppy, USB flash disk, SD card, CF card, USB lug-in board, Bluetooth and etc

Toy & stationery: documents folders, photo album, folding box, PP cavity board, Pen cover, ink box, toner cartridge, etc

Medical & daily use: watch, kitchen ware, oral liquid bottle cap, drip bottle cap, anti counterfeit bottle cap, cosmetic bottle cap, mobile phone accessories, gold soft brush, toilet articles, children applicant, air mattress, hanger, knife handle, gardening appliance, sanitary fittings, sprinkler, shower head, coffee pot, washing machine, air dryer, electric iron, electrical kettle, cleaner, metal cover of loudspeaker box, construction grating and etc

Please send KEEPLEADER™ your sample picture, advise us its material, size that can quick access to your application in making a proper quotation

Principle of turntable plastic ultrasonic welder

Ultrasonic welder operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates, frictional heat is produced, so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time, the melting points of both working pieces is nearly equivalent which helps to form a uniform weld are, the welded area is usually as strong as the matrix material

Turntable plastic ultrasonic welder adopts ultrasound and slicer together to complete whole continuous ultrasonic welding, which is suitable for the manufactures requires mass production for welding, it can be selected to install PLC, automatic feeding, automatic take-out device to improve automatic production, at at KEEPLEADER™, ultrasonic welding is only one of sealing methods, also have hot melt welding, vibrating friction, spin friction welding, hot air welding and etc, depends on the practice

Advantage of turntable plastic ultrasonic welder at KEEPLEADER™

Ultrasonic plastic welding is instant and efficient, the process is simple and yields high productivity, plastic ultrasonic welder reduces labor cost and the need to use fasteners and yields cleaner looking assemblies

Jointing mode of ultrasonic welder at KEEPLEADER™

01: Butt joint

02: Scarf joint

03: Step joint

04: Tongue and groove joint

Character of turntable plastic ultrasonic welder at KEEPLEADER™

01: high efficiency and batch production

02: None auxiliary material, harmless

03: Firmly bonded, no distortion or damaged

04: high air tightness and water proof of welding effect

05: Piezoelectric ceramic transducer imported, output is strong and stable

06: Anti-backwards and coaxial direct pressure design to improve welding precision

07: Touch screen, parameter set intuitional and exact

08: Imported main electrical components

09: high precision segmentation imported from Taiwan

10: Unique design of level screw, mold easy to debug

11: High Q value transducer, strong output

12: Turbine design, adjust trip easily, alloy amplitude transformer

13: 3 to 24 station can be selected, straight line oriented bearing

Introduction of KEEPLEADER™

Who KEEPLEADER™ are?

KEEPLEADER™, the premier global manufacturer of customized ultrasonic welding machine, our sales office is in Hongkong, factory locates in Shenzhen city, except for ultrasonic welding, KEEPLEADER™ is also engaging on ultrasonic cleaning, and various packaging machine in sealing field

What KEEPLEADER™ do?

KEEPLEADER™ manufactures quality ultrasonic welding machine for thermoplastic jointing practice, CNC shop also can provide matched ultrasonic mold for each practice, KEEPLEADER™ has stocked machine that can satisfy urgent order and sample testing purpose

KEEPLEADER™ an industry leader in ultrasonic welding field

Quality, Durability, value: KEEPLEADER™ has built a quality global reputation based on these core principle

Contact Us

Making air humidifiers without the right plastic assembly systems can cost your time and money, you risk falling behind competitors that are consistently making quality humidifier for less, keepleader, we adopt combined welding heads to apply ultrasonic vibration covering the whole geometry of large contour, the melting force is sufficient to get the target uniformity, thanks for our technique team, works out a compatible acoustic tools to march this ultrasonic welder in prominent resonance,moreover, the users are unnecessary to worry about the possibility of ultrasound squealing because of unmatched resonant, we’d like to share more salient advantages of Double Head Ultrasonic Welder Plastic Welding Machine, please don’t hesitate to contact us

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader