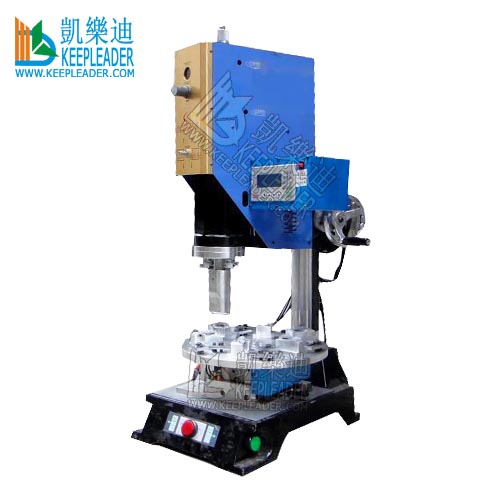

Rotary Table Ultrasonic Welder Plastic Welding Machine of Multi-Station Ultrasound Frequency Conversion Bonding HF Assembly Unit

Rotary Table Ultrasonic Welder Plastic Welding Machine

Rotary Table Ultrasonic Welder Plastic Welding Machine achieves automatic thermoplastic assembly process of molded-injection parts with turntable indexing system per ultrasonic frequency wave generated heat in melting and solidification, the standardized ultrasonic welding equipment gains prevalent gratification because of its integrated rotary table indexing, that is a durable. Efficient and safe solution for those seeking a reliable and high-quality bonding assembly system, tabletop ultrasonic welder couples robust frame with electronically indexed dial table, light curtain-protected load and unloading system, auto eject system, part presence sensor and other safety mechanisms all can be considered in combination.

Product description

Mainly application | |

Rotary Table Ultrasonic Welder Plastic Welding Machine, which is used for small plastic parts welding with easy position welding interface, the machine also can add robot arm for automatic unload | |

Character | |

Imported high precision cam divider, positioning precision Can equipped with robot arm electric precision fine-tuning limit, high precision IC circuit precision control, automatic overload protection system Have resonant frequency when the load, unload, without adjustment for the frequency of welding horn Using the turbine rotation to adjust the machine movement, which is better than normal Adopting Japan HuangPai brand alloy steel to keep frequency strong and stable | |

Mainly Parameter | |

Model | KLC-2020T |

Input power | 2000W |

Frequency | 20KHZ |

Input voltage | 110V/220V |

active horn | 70mm |

Cooling system | Air cooling |

Pressure | 1~ 7bar |

Welding size | Diameter: 180mm |

Oscillation system | Auto-stimulating |

Aire compressor | 1HP |

Productivity | 30~30pcs / min |

Output time | 0.01-99S |

weight | 280kgs |

Overall size | 850*960*1750mm |

Detailed Images

Rotary Table Ultrasonic Welder Plastic Welding Machine integrates automatic turntable indexing system with standardized table-top ultrasonic plastic welder, that can significantly increase productivity, because of working console is unmounted, which is additional cost-efficiency, Rotary Table Ultrasonic Welder Plastic Welding Machine is regarded as reliable plastic assembly system, where high frequency ultrasonic acoustic vibrations are applied to work-pieces that are hold together under controlled compression to create a solid state weld, ultrasonic welding is commonly used for plastic, and especially for jointing unrelated materials, in ultrasonic welding, there are not connective rivets, bolts, nails, soldering materials, or adhesive required to fix the materials together, to determine which size ultrasonic welding machine you need, first consider the size of the part being welded, 15khz Rotary Table Ultrasonic Welder Plastic Welding Machine is for large size, however 20khz is better for corresponding small delicate parts

Product uses

Rotary Table Ultrasonic Welder Plastic Welding Machine has rotary indexing system, that improve productive output in ultrasonic welding, that is solid-state bonding in molecular agglomeration, the ultrasonic vibrating energy applies indirectly heat through high frequency waves joint thin pieces of thermoplastic, it is highly energy efficient, without the need for fasteners or consumables, keepleader, we brings decade of experience to ultrasonic welding in addition to cutting-edge technologies that support new application n medical equipment, automotive, electronics, packaging and other rapidly evolving industries

FRQ

Q: Are you a dealer or manufacturer?

Ans: KEEPLEADER is a professional supplier of design, building, and marketing in plastic welding field

Q: What payment do you accept?

Ans: For first order, we accept 100% T/T before shipment, for repeated orders, we accept 50% advance, 40% before delivery, 10% after receiving

Q: Can we get sample machine?

Ans: KEEPLEADER only provide sample machine with updated design for our long-term cooperators, for first order or cooperation, KEEPLEADER can provide all of technical assistance for confirmation before ordering

Q: Can we print our own brand or logo?

Ans: Yes, KEEPLEADER accepts OEM order and customized design, configuration

Q: What certification does this machine have?

Ans: CE and RoHS

Q: Is my own forwarder available to transport the machine for me

Ans: Yes, KEEPLEADER accept nominated forwarder, or third part to arrange the shipment

Finction illustration

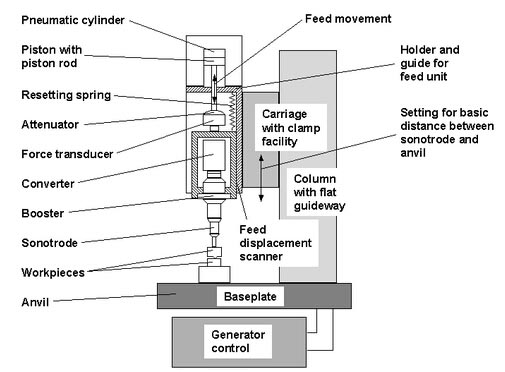

The basic principle of Rotary Table Ultrasonic Welder Plastic Welding Machine

01: Parts in fixture

The two thermoplastic parts to be assembled are placed together, one on top of the other, in a supportive nest called fixture

02: Horn contact

A titanium or aluminum component called a horn is brought into contact with the upper plastic part

03: pressure applied

A controlled pressure is applied to the parts, clamping them together against the fixture

04: welding time

The horn is vibrated vertically 15khz or 20khz times per second, at distances measured in thousandth of an inch (microns), for a predetermined amount of time called weld time, through careful part design, this vibratory mechanical energy is directed to limited points of contact between the two parts

The mechanical vibrations are transmitted through the thermoplastic materials to the joint interface to create frictional heat, when the temperature at the joint interface reaches the melting point, plastic part melts and flows, and the vibration is stopped, this allows the melted plastic to begin cooling

05: Hold time

The clamping force is maintained for a predetermined amount of time to allow the parts to fuse as the melted plastic cools and solidifies, this is known as hold time. (Note: improved joint strength and hermetic bonds may be achieved by applying a higher force during the hold time, this is accomplished using dual pressure)

06: Horn retracts

Once the melted plastic has solidified, the clamping force is removed and the horm is retracted, the two plastic parts are now joined as if molded together and are removed from the fixture as one part

Plastics assembly is fast, clean, efficient, and repeatable process that consumes very little energy, no solvents, adhesives, mechanical fasteners, or other consumables are required, and finished assemblies are strong and clean

Buying Guides

Application of Rotary Table Ultrasonic Welder Plastic Welding Machine at KEEPLEADER™

Field ranges: Automotive electronic, home appliance, industrial components, electrical wiring components, lighters, toys, gadgets, medical, personal appliances and related

For example; Suitable material: It is widely used in welding ABS, PE, PS, PVC, PP, ABS and PC synthetic, Acryl, etc, KEEPLEADER™ can do customized design and modified machine to accommodate our clients’ unique and special requirements

Plastic parts of automobile body: Car door, automobile instrument, car light and mirror, sun visor, interior trim parts, filter, etc, reflectorized material, reflectorized spike, fender-guard, inhaul cable, plastic filter for motorcycle, radiator, oil reservoir, oil cup, water tank, fuel tank, air hose, exhaust purifier, and tray filter board, etc.

Plastic electron: prepayment water meter, ammeter, communication apparatus, cordless telephone, accessories of mobile phone, cover of mobile phone, battery case, charger, valve controlled seal maintenance lead-add battery, 3-inch floppy, USB flash disk, SD card, CF card, USB lug-in board, Bluetooth and etc

Toy & stationery: documents folders, photo album, folding box, PP cavity board, Pen cover, ink box, toner cartridge, etc

Medical & daily use: watch, kitchen ware, oral liquid bottle cap, drip bottle cap, anti counterfeit bottle cap, cosmetic bottle cap, mobile phone accessories, gold soft brush, toilet articles, children applicant, air mattress, hanger, knife handle, gardening appliance, sanitary fittings, sprinkler, shower head, coffee pot, washing machine, air dryer, electric iron, electrical kettle, cleaner, metal cover of loudspeaker box, construction grating and etc

Please send KEEPLEADER™ your sample picture, advise us its material, size that can quick access to your application in making a proper quotation

Principle of turntable plastic ultrasonic welder

Ultrasonic welder operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates, frictional heat is produced, so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time, the melting points of both working pieces is nearly equivalent which helps to form a uniform weld are, the welded area is usually as strong as the matrix material

Turntable plastic ultrasonic welder adopts ultrasound and slicer together to complete whole continuous ultrasonic welding, which is suitable for the manufactures requires mass production for welding, it can be selected to install PLC, automatic feeding, automatic take-out device to improve automatic production, at at KEEPLEADER™, ultrasonic welding is only one of sealing methods, also have hot melt welding, vibrating friction, spin friction welding, hot air welding and etc, depends on the practice

Advantage of turntable plastic ultrasonic welder at KEEPLEADER™

Ultrasonic plastic welding is instant and efficient, the process is simple and yields high productivity, plastic ultrasonic welder reduces labor cost and the need to use fasteners and yields cleaner looking assemblies

Jointing mode of ultrasonic welder at KEEPLEADER™

01: Butt joint

02: Scarf joint

03: Step joint

04: Tongue and groove joint

Character of turntable plastic ultrasonic welder at KEEPLEADER™

01: high efficiency and batch production

02: None auxiliary material, harmless

03: Firmly bonded, no distortion or damaged

04: high air tightness and water proof of welding effect

05: Piezoelectric ceramic transducer imported, output is strong and stable

06: Anti-backwards and coaxial direct pressure design to improve welding precision

07: Touch screen, parameter set intuitional and exact

08: Imported main electrical components

09: high precision segmentation imported from Taiwan

10: Unique design of level screw, mold easy to debug

11: High Q value transducer, strong output

12: Turbine design, adjust trip easily, alloy amplitude transformer

13: 3 to 24 station can be selected, straight line oriented bearing

Introduction of KEEPLEADER™

Who KEEPLEADER™ are?

KEEPLEADER™, the premier global manufacturer of customized ultrasonic welding machine, our sales office is in Hongkong, factory locates in Shenzhen city, except for ultrasonic welding, KEEPLEADER™ is also engaging on ultrasonic cleaning, and various packaging machine in sealing field

What KEEPLEADER™ do?

KEEPLEADER™ manufactures quality ultrasonic welding machine for thermoplastic jointing practice, CNC shop also can provide matched ultrasonic mold for each practice, KEEPLEADER™ has stocked machine that can satisfy urgent order and sample testing purpose

KEEPLEADER™ an industry leader in ultrasonic welding field

Quality, Durability, value: KEEPLEADER™ has built a quality global reputation based on these core principles, and KEEPLEADER™ takes pride on delivering every customer the ultimate in satisfaction, you can count on KEEPLEADER™ to lead the ultrasonic welding machines market producing new and exciting ultrasonic welding solutions, KEEPLEADER™ are innovators in plastic ultrasonic welder

Contact Us

Keepleader, we are customer centric thought leaders, we partner with you to construct the best plastic joining solution for your plastic parts, additionally, we are application experts with the largest portfolio of plastic jointing, sealing or cutting solutions, and we can organize the prominent solution for your application, Rotary Table Ultrasonic Welder Plastic Welding Machine gains prevalent advantages of compact structure, affordable price and convenient operation, furthermore, we believe that we possess several attributes for which our Rotary Table Ultrasonic Welder Plastic Welding Machine associates and customers desire to be a part of our construction endeavor, such as strong infrastructure, experience team, open-loop cooperative criteria, customer-oriented business approach, emphasis on maintaining the quality of offered ultrasonic welder, cost-effectiveness and high efficiency of products, honest business policy and on-time product delivery system, don’t hesitate to consult with our expertise, believe we can start a thrilling collaborative Journey

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader