Surgical Gown Making Cuffs Sealing Ultrasonic Sewing Machine of Medical_Protective PET Cloth Wireless Suture Stitching Equipment

Surgical Gown Making Cuffs Sealing Ultrasonic Sewing Machine

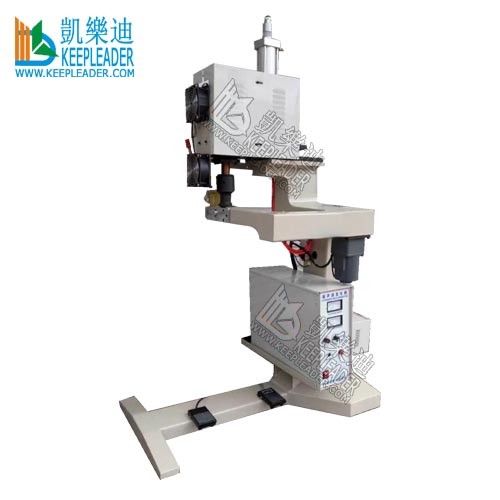

Surgical Gown Making Cuffs Sealing Ultrasonic Sewing Machine is one of the alternatives to conventional sewing methods in making surgical gown,ultrasonic energy provides savings, efficiency and clean producing, in medical clothing production,many problems encountered in traditional sewing have reached destructible levels with ultrasonic sewing, where the surgical gown made of PP,PET is sutured via ultrasonic vibrating localized joints in molecular level,the polymer cloth melts and combines and forms a bond, moreover, “U” shaped structure of frame is convenient for cuffs sealing of looped sleeve

Product description

Surgical Gown Making Cuffs Sealing Ultrasonic Sewing Machine

01: Parameter

Model | KLC-3U |

Ultrasonic power | 1.5kw |

Power supply | 220v/ 50hz, 6A |

Ultrasonic frequency | 20khz |

Working speed | 0-14mm/min |

Maximum stitching width | 75mm |

Weight | 280kgs |

Packing size | 1.3*0.8*1.2m |

MFR:KEEPLEADER™ have modified and designed Surgical Gown Making Cuffs Sealing Ultrasonic Sewing Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details | |

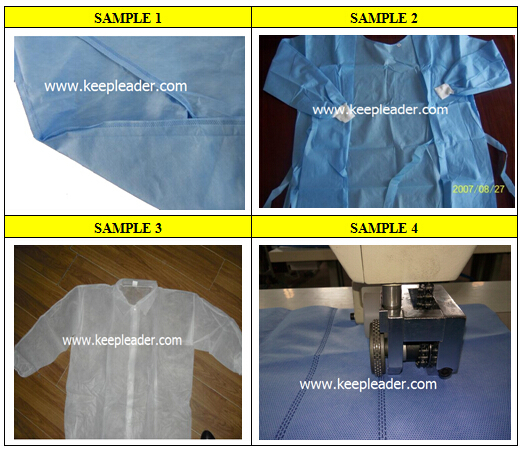

02: Application

Lace clothing, skirt rim, sprotwear, pajamas, medical gown, hair decorations, packaging satin, colored ribbon, tent, raincoat, tablecloth, chair cover, bedspread, pillowcase, quilt cover, curtain, handkerchief, colored flag, disposable operation coat, model mask, non spin respirator, handicraft, decorations products and etc.

03: Suitable material

Composite material, thermoplastic film and plastic slice, such as chemical fibrous cloth, nylon cloth, knitting cloth, non spin cloth, gush glue cotton, PE paper, PE+ aluminum, PE+ cloth, and so on.

03: Function and characters

031: cutting and trimming can be completed at same time, which can avoid roughness and no coarse side and keep the cutting edge smooth

032: Making hole: the holes with various pattern, diameter, shape can be cut and treatment of side melting can be carried out too

033: Transfer printing: two layers or multi-layers can be melted together, it is not necessary to use tread and needle, the process can replace sewing, moreover the melted strength is excellect

034: Forming, cutting, melting, printing, embossing and trimming in one process: the knurling roller is machined with all of these functions

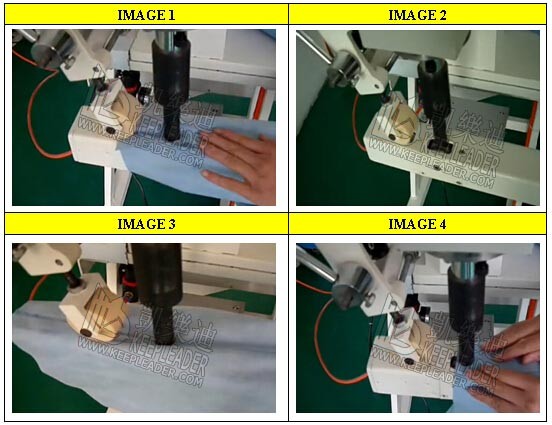

Detailed iamges

Surgical Gown Making Cuffs Sealing Ultrasonic Sewing Machine is mainly responsible for solving the suturing problem of surgical gown, at this stage, surgical gowns are mainly sutured by 45 degree oblique stitches, and the sealing effect is not good and there are drawbacks, once the surgical gown is off the line, the sealing edge will crack, ultrasonic seamless sewing sutures without needle, treads and pinholes, ultrasonic vibrated energy is concentrated on the sutured fabric of the surgical gown to generate the heat, the joining seam quickly melt and the pressure merges into one after instant solidification, the pinhole-free seamless treads meas completely reliable sealing and not easy for break,moreover,the ultrasonic sealing suture perform a good cosmetic appearance

Product uses

Surgical Gown Making Cuffs Sealing Ultrasonic Sewing Machine is energy saving method, it is seen as processing solution that is easier to recycle since materials such as tread used in conventional sewing methods are not needed, ultrasonic bonding method is used in different polymer clothing industry, such as surgical gown, protective cloth, medical shading cloth, protective cover, respirator and relative Medical consumables in clothing

After-sales service

After purchasing at KEEPLEADER™ is first step of our after-service, all of machines at KEEPLEADER™ has one year guarantee, we provide free samples for defected parts to do replacement except for human damage, under information for your notice

01: KEEPLEADER™ always posts the new technical file in our homepage that can help our client in new technical information of machines’ design, character, application, operation, maintenance,

and related, KEEPLEADER™ also welcome our clients feed back the machines’ working condition that can get one to one service

02: If the machine you purchased has any defects, please contact sales representative at KEEPLEADER™, we will assign our experienced engineer analyze your case and provide technical support, in case of damaged parts that cannot repair, KEEPLEADER™ will provide a new parts to replace the defect

03: For any replacement and maintenance, KEEPLEADER™ has user manual and training video

04: KEEPLEADER™ can go to oversea for on-site training

05: KEEPLEADER™ can provide electric diagram if in need

Contact Us

Surgical Gown Making Cuffs Sealing Ultrasonic Sewing Machine is reliable solution in surgical gown making, particularly for auto feeding of looped sleeve, curved seam process, pedal valve controls the operation in flexible adjustment of speed, feeding shape and pause, thanks for experienced technique of keepleader, they strive to satisfy the clients’ demand in flexible production at affordable price, the bespoke ultrasonic cloth sealing machine is also acceptable, our construction can combine all of verified specification into one machine,please don’t hesitate to consult our sale representatives, they will work with our tech depth to innovate your concerns into our tenets for your final validation of our accomplishment

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader