Corflute Sheet Welding PP Corrugated Box Ultrasonic Spot Welder of Coroplast Boards Soldering Turnover Totes Ultrasound Welders

Corflute Sheet Welding PP Corrugated Box Ultrasonic Spot Welder

Corflute Sheet Welding PP Corrugated Box Ultrasonic Spot Welder obtains recognition among competitors with its particular advantages below

Usable weld throat depth up to 500mm are standard

Stable pedestal counted with robust column to achieve max loading height 1300mm

Generator mounted next to press for convenient operator viewing and setup

Strong, welded steel extension arm with universal fixture pad

Flexible mounting slot to install fixture for versatile size in production

Welding depth, power, time and pressure all are adjustable

Product description

Corflute Sheet Welding PP Corrugated Box Ultrasonic Spot Welder | |

Characters | |

IC circuit precision control, automatic overload protection system | |

Basic parameter | |

Model | KLC-2615L |

Input power | 2600W |

Frequency | 15KHZ |

Input voltage | 110V/220V |

Horn Stroke distance | 70mm |

Oscillation system | Auto-stimulating |

Output time | 0.01-99S |

Pressure | Pressure bound 1-7bar |

Welding area | 200mm |

Compressor | 2HP |

Net weight | 100kg |

MFR: KEEPLEADER™ have modified and designed Corflute Sheet Welding PP Corrugated Box Ultrasonic Spot Welder for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

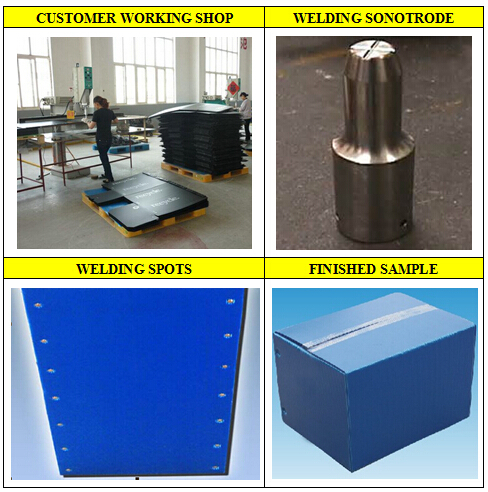

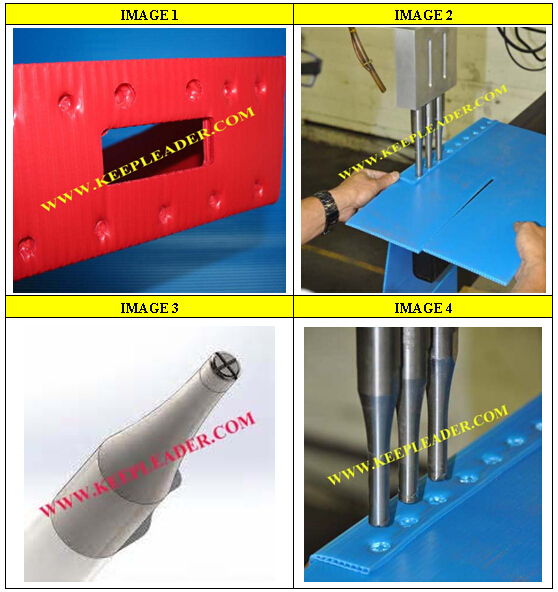

Produce uses

Corflute Sheet Welding PP Corrugated Box Ultrasonic Spot Welder integrates robust column with stable pedestal to form a loading depth in corrugated box making, ultrasonic welding machine stands on the top extended frame to suffice to spot bonding depth, the finished corrugated plastic box is a new type of turnover box in the logistics packaging industry, people also call it correx box, corflute box or coroplast box, it also can be called corrugated plastic bin, corrugated plastic totes and corrugated plastic containers

Contact Us

Corflute Sheet Welding PP Corrugated Box Ultrasonic Spot Welder is only of ultrasonic welding technical solution in corflute box making, we, keepleader is not only a professional manufacturer but also a reliable cooperator to work with you in improving your productivity at an affordable pricing, please contact us to find what more we can do for you

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader