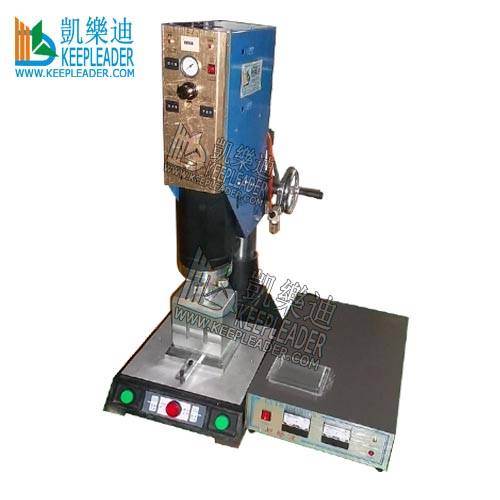

PVC PET Blister Packaging Welder Ultrasonic Welding Machine of Plastic Clamshell Packing Heat Sealing Ultrasound Bonding Sealer

PVC PET Blister Packaging Welder Ultrasonic Welding Machine

PVC PET Blister Packaging Welder Ultrasonic Welding Machine acts as molecular bonding in plastic blister packaging process, which eliminates the use of glue and allows the blister halves instant sealing at any specific time and occasion, in addition, ultrasonic blister welder results in sealing of water-proof and air-tight if requested, the circle processing time is less one seconds for efficient production, no preheated procedure and gluing process involve in the welding works is cost-effective and more reliable method than any conventional recipe

Product description

PVC PET Blister Packaging Welder Ultrasonic Welding Machine

01: Parameter

Model | KLC-2615P | KLC-3215P | KLC-4215P | KLC-5215P |

Frequency | 15khz | |||

Output power | 2.6kw | 3.2kw | 4.2kw | 5.2kw |

Welding size | 200 | 220 | 250 | 280 |

Power source | 110-220v/50/60hz | |||

Input power | 1.2kw | 1.9kw | 2.3kw | 2.7kw |

Stroke distance | 70mm | |||

Vibration System | Auto-stimulation | |||

Pneumatic | 2-9 bar | |||

Air compressor | 1HP-4HP | |||

Cooling | Fan cooling | |||

Net weight | 110kgs | 110kgs | 150kgs | 180kgs |

Dimension | 650*420*1300 | |||

02: What is Blister ultrasonic welder?

Blister ultrasonic welder uses high-frequency vibration to melt and weld plastic blister, clamshell, a tool vibrates at ultrasonic frequencies and causes concentrated molecular vibration in the weld joint, the friction between the molecules heats and melts the plastic, once the vibration is stopped, the tool maintains a holding pressure on the joint to create bond

03: Advantage of blister ultrasonic welder

Low cost energy efficient and economical

The safe process in blister sealing, no high frequency damage to electrical circuits or wiring, environmentally safe and recyclable

High speed up to five times faster that high frequency sealing

Space saving, small footprint fits anywhere

Seals all these materials: PET/ETE, PETG/RPET, PVC, polystyrene, polypropylene

Aesthetically pleasing: seal patterns are limitless

Tamper proof

04: Typical uses of ultrasonic welders include

Bench top style plunge sealers

Bench-top semiautomatic systems for end of line flexible conveyors

Hand held small ultrasonic spot welder for low volume small seal areas

Rotary systems with automatic eject stations for higher volumes

Less base models for integration into your automatic packaging systems

05: Packaging application ideal for ultrasonic sealing

Aseptic | Microwave/oven board |

Bagging | Pouches |

Carton | Medical |

Clamshell/blister packaging | Spouts |

Corrugate plastic (mail totes, etc) | Strapping |

Cups | Tamper evident/ evident/safety cups |

Shrink wrap packaging | Tubes |

| Zip lock bags |

MFR: KEEPLEADER™ has modified and designed PVC PET Blister Packaging Welder Ultrasonic Welding Machine to accommodate our customers’ unique and special requirements, pls contact KEEPLEADER™ for tech assessment

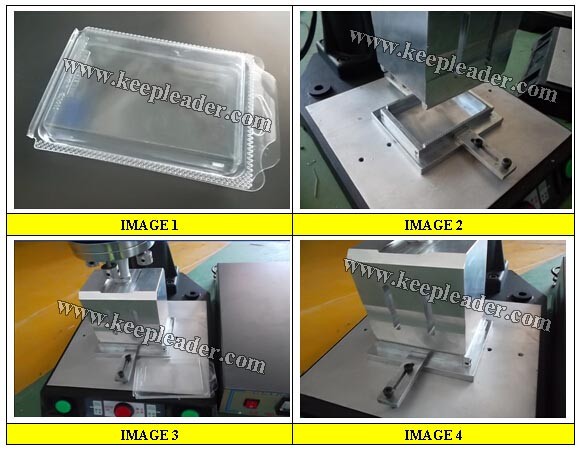

Detailed iamges

PVC PET Blister Packaging Welder Ultrasonic Welding Machine installs coupled tooling in exert pressure, holding and friction bonding, we will design the ultrasonic horn in compliance with your blister in shape, size and structure, if the depth of blister half is over the frictional limit, we will build a ultrasonic horn with pins to avoid horizontal depth problem

Buying guides

Application of Blister Ultrasonic welder

Ultrasonic welder is one of considerable process in the field of blister packaging

According to our experience, most of thermoplastic packaging also can be processed by ultrasonic welder, which is partially competitive that hot melting sealing and high frequency sealing, KEEPLEADER can design the jointing pattern to achieve various sealing effect

Advantages of Blister Ultrasonic welder

Reducing the processing time, each circle process is less one seconds

Using ultrasonic welder in blister sealing is stable, save cost, reliable

Ultrasonic welder only process its jointing area, high efficiency and economic

No need reheating, total cold process, no any temperature caused

Don’t need expensive and contaminative auxiliary

Can penetrate the dirty (liquid, grease, power etc) in sealing process

Can equipment with automatic production line

Blister ultrasonic welder in its possible treating material

Material | coating | Sheet covering | Flim | Foam |

Ionomer (SurlynR) | G | G | G | -- |

PET / PETE | -- | -- | -- | E |

PETG / RPET | -- | -- | -- | E |

Polyethylene | E | E | E | -- |

Polypropylene | E | E | E | E |

PVA | G | G | G | -- |

PVC | G | G | G-P | E-G |

Styrene | G | G | G | E |

Urethane | E-G | -- | E-G | -- |

Note: E=Excellent, G=Good, F = General, P = Not good, -- = unavailable

Product uses

PVC PET Blister Packaging Welder Ultrasonic Welding Machine applies in versatile bonding connection of thermoplastic, its geometry of ultrasonic horn and ultrasonic power output always cater to practical welding object, except for solid plastic of mold injection, can exert fabric, flexible product seam joining, particularly in the blister packing field, the PET material is weldable by ultrasonic friction, the compact structure saves the working space, instantly soft and solidify the joining interface to achieve the blister halves sealing with eye-catching appearance without any additional consumption

keepleader, we has always adhered to the tenet of “high quality service and abiding by the contact” with high quality products, good reputation and quick-response service, PVC PET Blister Packaging Welder Ultrasonic Welding Machine is favored in the market of plastic blister bonding in molecular scale,we don’t take profit as the goal, don’t take the scale of assets,don’t cater to the market with low price and reduce the quality of products, all of our staff will meet the new challenges with a new attitude and adhere to strict scientific management, believe that innovation creates the future and uphold the faith of innovation, sharing, cooperation and double win,we’d like to accomplish your concerns as our satisfaction,now it is time for us to start from your initiation

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader