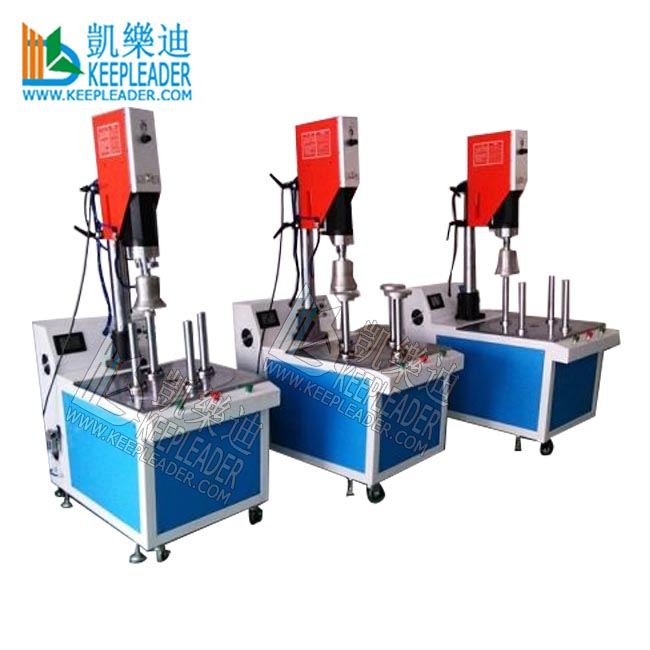

Rotary Table Plastic Welder Ultrasonic Welding Machine of PE_PVC Cylinder Box Bottom Sealing Cylindrical Pack Supersonic Sealer

Rotary Table Plastic Welder Ultrasonic Welding Machine

Rotary Table Plastic Welder Ultrasonic Welding Machine utilize the principles of ultrasonic energy to join bottom of PVC/APET/PETG/PP Cylindrical boxes, welding tools Viz: columnar anvil or supportive fixture focus the ultrasonic energy on the circular sealing position at which the welding should take place, the friction heat is generated, the sealing time is between 100 and 200 milliseconds, unlike heat sealing, the heat required in ultrasonic technology is solely generated within the material at joining line, the tool remain cold and support the dissipation of heat, the hot take resistance, Viz strength of seam directly after welding without cooling, is also significantly higher than with hot melt welding or gluing methods, the speed, reliability and overall quality of the welding cylindrical container make plastic welder ultrasonic welding machine vital across clear cylindrical boxes packaging process

Product description

Characters | |||

IC circuit precision control, automatic overload protection system | |||

Mainly parameter | |||

Model | KLC-2615 | KLC-3215 | KLC-4215 |

Input power | 2600w | 3200W | 4200W |

Frequency | 20KHZ | ||

Input voltage | 220V | ||

Max input power | 1.2KW | 1.9KW | 2.3KW |

Active horn | 70mm | ||

Oscillation system | Auto-stimulating | ||

Output time | 0.01-99S | ||

Pressure | Pressure bound 1-7bar | ||

Welding area | 200mm | 220mm | 250mm |

Compressor | 1HP | ||

Net weight | 110kg | 100kg | 115kg |

Detailed Images

Rotary Table Plastic Welder Ultrasonic Welding Machine adopts universal ultrasonic vibration bonding technique to seal disc onto end of tube in plastic cylinder box making, automatic turntable indexing integrates in ultrasonic welder with motive console, that satisfies flexible production at cost-efficiency and higher productivity, ultrasonic welder in clear cylindrical container packaging creates a strong, clean and solid-state seal, which increasing production without quality concession, the factories usually combine this bottom sealing machine with other production machines to organize production line, like, cylinder tube forming, edge curling, and other corresponding integration without using the consumables, ultrasonic welding technology helps you meet environmental goal by increasing reliability and eliminating chemicals adhesives and solvents

Product use

Rotary Table Plastic Welder Ultrasonic Welding Machine gains gratification in plastic cylinder box making for bottom sealing assemble,clear cylindrical container packaging perform eye-catching,that made of PVC,APET,PETG, used for advertising packing in field of candy, gift, toys, stationary, umbrella, fishing tools. Crisp food and fashion food and etc, the popularity is increasing because of cost-efficiency and appealing appearance and marketing inspection

Our service

Before purchasing

01: Sales representative will confirm your requirements in details

02: proposal the correct model for your comments

03: reach a final confirmation of production flow with all of necessary model in production

04: provide the official quotation

among production

01: will provide the updated status in production per 2 to 3 days

02: take video and picture to keep the customers posted

03: prepare the paper documents for shipment

04: confirm the shipping information

after order

01: provide the training service

02: collect the tech files related in machine's install, debugging, maintenance

03: provide the updated on the machine's new inhanced design, funcation and etc

Rotary Table Plastic Welder Ultrasonic Welding Machine is motive ultrasonic welder with automatic rotary table indexing, its frequency and power output scale depend on cylinder tube diameter, for precise welding cylinder box bottom in Plastic Welder Ultrasonic Welding Machine to take place, the energy from the ultrasonic waves must be focused, Viz energy focusing, this is either achieved via the tool geometry or the joint design on the material, in case of joint design, they are at which the material is to be jointed has special shapes such as points or edges, in case of tool geometry, ultrasonic horn or the anvil are specially shaped to focus the energy, hence, we designate supportive pole to insert cylinder tube, solely apply pressure on the bottom, but ultrasonic vibration melting happen solely at the extruded spherical teeth

Contact Us

At keepleader, we will be able to help you find the ring kind of assembling technology for your cylinder box production, in most cases, Rotary Table Plastic Welder Ultrasonic Welding Machine is a very efficient approach to reliably seal plastic cylinder bottom comparing with gluing, it is cost-efficient and environment-friendly, for any further information or to speak with one of our engineers, favor you email us or contact online, we will always be able to recommend the right sealing technology for your PVC/APET/PETG Cylinder container bottom mounting. And offer free feasibility and assistance in the joints design,we look forward to assisting you, continuously contact us to find what more we can do for your production

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader