LED Tube Plug Welder Horizontal Plastic Welding Ultrasonic Machine of Double Heads_Guardrail_Lamp Pipe Ultrasound Bonding Device

LED Tube Plug Welder Horizontal Plastic Welding Ultrasonic Machine

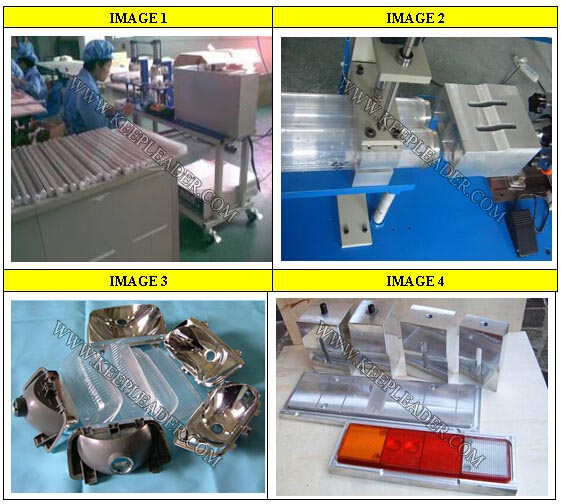

LED Tube Plug Welder Horizontal Plastic Welding Ultrasonic Machine adopts pneumatic actuator in horizontal pressing, which takes short journey in applying pressure when ultrasonic frictional melting light tube plug at lowest deviation, ultrasonic displacing joints in molecular scale achieves bonding plugs of lighting tube results in a water-proof and air-tight effect without consumable material, such as adhesive, filler, solvent, bolts or clip,it has the advantages of simple operation, fast welding speed, high welding strength and high production efficiency, therefore, ultrasonic welding technology gets more and more widely used, this horizontal type ultrasonic welding device suits for tube, pipe or long-standing assemble thermoplastic parts, particularly reliable for end sealing of LED guardrail tube,descent lighting bulb, lamp tube, plastic tube, plastic pipe and other tubular objects

Product description

Principle of LED guardrail tube ultrasonic welding machine | |||

The basic principle and characteristics of Plastic Guardrail tube sealing machine, LED guardrail tube welding machine, parapet light welding equipment, guardrail tube double-head sealing and welding machine: 20KHZ produced by ultrasonic generator voltage, frequency of the signal, through the piezoelectric transducers with frequency conversion into reverse effect of mechanical vibration. The basic principle and characteristics of Plastic Guardrail tube sealing machine, LED guardrail tube welding machine, parapet light welding equipment, guardrail tube double-head sealing and welding machine also has audio wave forms in the plastic products, through the surface of work piece and internal friction between the molecules that transfer to interface temperature, when the temperature reached work piece itself melting point, the work piece, then rapidly melting interface to fill the gap between interface, while shaking stops at the same time, the work piece under the pressure of certain cooling shapes, reach perfect welding. KEEPLEADER will offer one-year free technical support and services, we also offer lifelong maintenance service | |||

Application | |||

Plastic Guardrail tube sealing machine, LED guardrail tube welding machine, for O, D, U-type fence tube plug seal welding, without adhesive bonding, to the extent watertight and pleasing in appearance, easy to use. Production of high efficiency, non-performing rate is low | |||

Features | |||

Ultrasonic plastic welder using the Switzerland original transducer, titanium amplitude transformer, the output power is large and stable, solid and durable. Smart aircraft design, linear guide device from Japan, four-point level of design for chassis, it's convenient to operate. The Switzerland high-quality automatic vibration constant balanced circuit, automatic frequency tracking function. Adopt Japan, Matsushita human-machine interface, PLC control, the time control accuracy up to 0.001 seconds. Easy to operate. Use automatic lift limited mode, convenient adjustment and high accuracy. Using visual tuning depth control mode, cylinder, transducer three in one direct-drive, and high welding stability. this machine is especially adapt to used in SD card, memory card, SM card, U disk, mobile phones and other microelectronics work piece welding. it is also suitable for precision welding of work pieces, riveting, embossing, dots and other welding processes Ultrasonic plastic welders operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates. Frictional heat is produced so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time. The melting point of both working pieces is nearly equivalent which helps to form a uniform weld area. The welded area is usually as strong as the matrix material. | |||

Parameter | |||

Model | KLC-1020DH | LC-1520DH | LC-2020DH |

Ultrasonic power | 2000W | 3000W | 4000W |

Welding size | 100MM | 150MM | 180MM |

Net Weight | 220KGS | 230KGS | 240KGS |

frequency | 20KHZ | ||

Cooling system | Fan cooling | ||

Vibration system | Self-stimulating | ||

Air compressor | 1HP | ||

Power supply | 110-220v/50hz/60hz | ||

Shape size | 560*360*960mm | ||

MFR: KEEPLEADER™ have modified and designed LED Tube Plug Welder Horizontal Plastic Welding Ultrasonic Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Product uses

In assembling of lighting tube plug by LED Tube Plug Welder Horizontal Plastic Welding Ultrasonic Machine, the user assembles the lighting tube horizontally under pneumatic clamping device, the lighting tube stops to bear the melting pressure at the end joints against the pneumatic activated weldable plug. Ultrasonic friction heating happens when jointing couples snap together in instantly melting, and ultrasonic melting stops, the melted plastic trapped line fills into the gap, solidified to accomplish robust bonding, this principle of welding stands out of conventional connecting method, ultrasonic wave acts on the thermoplastic, its will produces tens of thousands of high frequency vibration per second, this high frequency vibration with a certain amplitude will transmit the ultrasonic energy to the welding area of tube end, due to the large acoustic assistance at the interface between the lighting tube and inserting plug, local high temperature will be generated, in addition, due to the pool thermal conductivity of the plastic, it can not be distributed in time, and gathered in the welding area, resulting in the rapid melting of the contact surface of the lighting tube with inserting plug, after a certain pressure is aded, it is integrated into one, when the ultrasonic wave stops working, let the pressure last for a few seconds to solidify and form, so at to form a solid molecular chain to achieve the purpose of welding, and the welding strength can be close to the strength of raw material, the quality of LED Tube Plug Welder Horizontal Plastic Welding Ultrasonic Machine depends on three factor, the amplitude and transducer welding head, the applied pressure and welding time, the welding time and welding heat pressure can be adjusted and amplitude is determined by transducer and horn, there is appropriate value for the interaction of these three quantities, when the energy exceeds the appropriate value, the melting mount of plastic is large and the welded joint is easy to deform, if the energy is small, it is not easy to weld firmly, and the added pressure cannot be too large,sufficient pressure is applied, but without overflow in jointing area

Buying guides

Brief introduction

Ultrasonic welding is primarily used for thermoplastic joining, compared with other plastic welding techniques, plastic ultrasonic welding has the advantages of excellent welding quality, high production efficiency and wide application, the advantage of excellent welding are extensive and are found in many industries inclucing electronic and electrical, automatic and aerospace, civil engineering, medical and packaging field

KEEPLEADER™ can develop kinds of automatic ultrasonic welding production line to meet customers’ unique requirements, standard ultrasonic welding machine can be divided into table-type and cabinet-type, for cabinet-type, a delicate plastic welder to facilitate operation

Characters of ultrasonic welding machine at KEEPLEADER™

01: Suitable for welding, PP, PS, PE, PC, ABS, PBT and etc

02: No need any adhesive or flux and less heat consumption

03: Easy operation, high efficiency, excellent outward appearance, and high strength

04: AIRTAC pneumatic components durability

05: Automatic and manual operating mode, convenient for adjusting

06: CE, SGS international quality certificate

07: One year warranty

FAQ

Q: Are you a dealer or manufacturer?

Ans: KEEPLEADER is a professional supplier of design, building, and marketing in plastic welding field

Q: What payment do you accept?

Ans: For first order, we accept 100% T/T before shipment, for repeated orders, we accept 50% advance, 40% before delivery, 10% after receiving

Q: Can we get sample machine?

Ans: KEEPLEADER only provide sample machine with updated design for our long-term cooperators, for first order or cooperation, KEEPLEADER can provide all of technical assistance for confirmation before ordering

Q: Can we print our own brand or logo?

Ans: Yes, KEEPLEADER accepts OEM order and customized design, configuration

Q: What certification does this machine have?

Ans: CE and RoHS

Q: Is my own forwarder available to transport the machine for me

Ans: Yes, KEEPLEADER accept nominated forwarder, or third part to arrange the shipment

ConQ: Are you a dealer or manufacturer?

Ans: KEEPLEADER is a professional supplier of design, building, and marketing in plastic welding field

Q: What payment do you accept?

Ans: For first order, we accept 100% T/T before shipment, for repeated orders, we accept 50% advance, 40% before delivery, 10% after receiving

Q: Can we get sample machine?

Ans: KEEPLEADER only provide sample machine with updated design for our long-term cooperators, for first order or cooperation, KEEPLEADER can provide all of technical assistance for confirmation before ordering

Q: Can we print our own brand or logo?

Ans: Yes, KEEPLEADER accepts OEM order and customized design, configuration

Q: What certification does this machine have?

Ans: CE and RoHS

Q: Is my own forwarder available to transport the machine for me

Ans: Yes, KEEPLEADER accept nominated forwarder, or third part to arrange the shipment

Contact UsLED Tube Plug Welder Horizontal Plastic Welding Ultrasonic Machine stands out of its competitors because of advanced assembly principle, convenient operation, custom configuration and built-in accuracy and efficiency, keepleader, we devote to bespoke facilities in plastic assembling of injection molded, our cooperative endeavour can yield twice the results with half effort

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader