Cross Flow Fan Blower Assembly Welding Ultrasonic Welder of Cooling Tower Plastic Wind Impeller Stacking Sonic Bonding Equipment

Cross Flow Fan Blower Assembly Welding Ultrasonic Welder

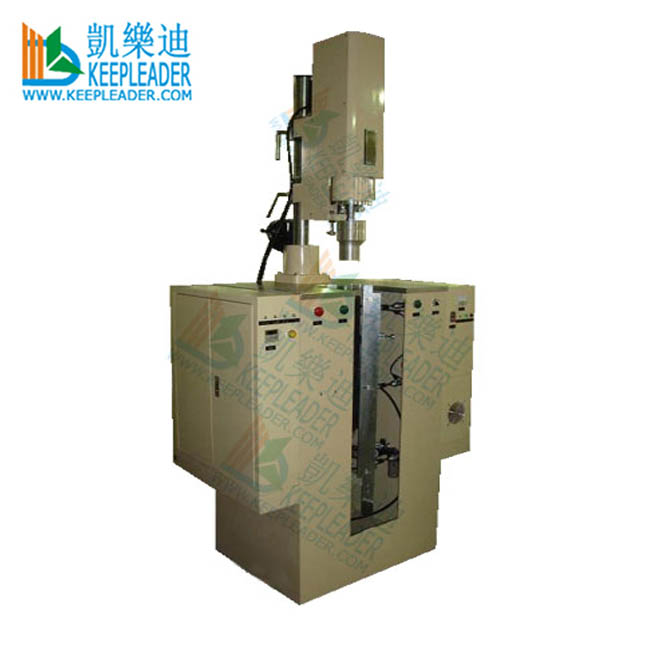

Cross Flow Fan Blower Assembly Welding Ultrasonic Welder is dedicated to cross-flow fan impeller/tangential fan blade welding equipment, this ultrasonic welder uses precision rolling screw and linear guide as moving part to ensure work position and durability of the fixture/clamping device,the work cycle is completed by programmable logic control system and servo device, once the split fan is placed in the working position, the whole process of clamping, welding, relaxation and displacement can be automatically operated, which has the simple operation, using the device in the mass production process, can improve production efficiency, ensure welded cross-flow fan quality and reduce production costs

Product description

| CHARACTER | |

With pneumatic holding and clamping device Manual and auto working is optional for welding and clamping IC circuit precision control, automatic overload protection system Adopting digital switch, 1/100 precision re-set control Adjustable horizontal level, easy control welding horn High Q transducer, optimized output Self phase-locking for frequency matching without manual adjustment Straight line guide bearing, the precise matching device Using the turbine rotation to adjust the machine movement, which is better than normal Adopting Japan Huangpai brand alloy steel to keep frequency strong and stable Celebrate itself durability for adopting USA aviation standard 7075 /6064 Al alloy Electronic components are imported from Italy, Japan, American, South Korean, Taiwan All in one high capacity machine, applied for high precision of welding work piece | |

| MAINLY PARAMETER | |

| Model | KLC-2615C |

| Input power | 2600w |

| Frequency | 15khz |

| Moving distance of active horn | 70mm |

| Oscillation system | Auto-stimulating |

| Output time | 0.01-99s |

| Pressure | Pressure bound 1-7bar |

| Welding diameter in max | 130mm |

| Welding length in max | 1000mm |

| Compressor | 1HP |

| Net weight | 300kg |

Product uses

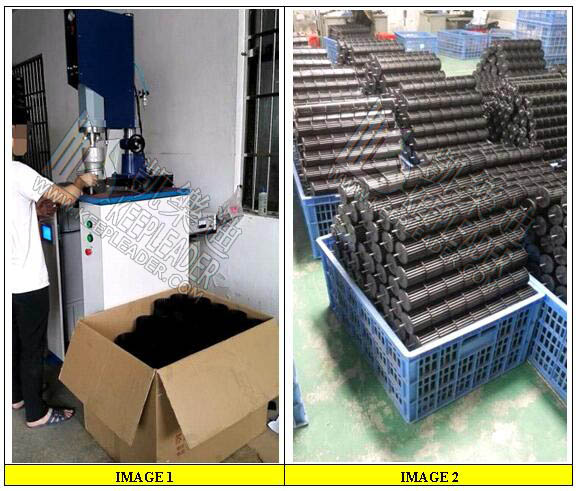

Cross Flow Fan Blower Assembly Welding Ultrasonic Welder has customized fixture/clamping device integrated in the universal ultrasonic welder, exclusive constructed ultrasonic welder with automatic clamping device solely dedicates to bond split Fan/cross-flow fan impeller/tangential fan blade, the PLC with touch screen control the servo-motorized clamping system to complete the whole process of assembling cross-flow fan impeller, ultrasonic welding machine is now widely used in automotive manufacturing, shipping aviation, electrical appliances, packaging, toys, electronics, stationery, medical equipment, environmental protection products, textile and other industries, has successfully achieved a variety of plastic welding such as ABS,AMMA, ARP,AS, PS,PP,PE,PE,PVA, acrylic and etc

Function illustration

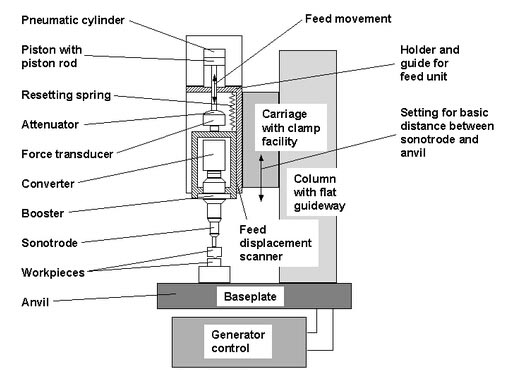

Cross Flow Fan Blower Assembly Welding Ultrasonic Welder takes principle of ultrasonic frictional melting to achieve bonding in molecular scale at the jointing area, ultrasonic wave acts on the thermoplastic contact surface, it will produce tens of thousand of high frequency vibrations per second, this kind of high frequency vibration with a certain amplitude will transmit the ultrasonic energy to the welding area through the upper horn, because of the welding area is two halves, the acoustic resistance is large at the welding interface, so local high temperature will be generated, in addition, due to the poor thermal conductivity of the plastic, it cannot be distributed in time for a while, it gathers in the welding are, causing the contact surface of the two plastics to melt rapidly, and after a certain pressure is applied, it merge into one, when the ultrasonic stops, let the pressure continue for a few seconds to make it solidify and shape, thus forming a strong molecular chain,achieving the purpose of welding, and the welding strength can be close to the strength of matrix material, the quality of plastic welding ultrasonic welder depends on three factors, the amplitude of the transducer’s welding head, the applied pressure and welding time, the welding time and head pressure can be adjusted, and the amplitude is determined by the transducer and the horn, there is an appropriate value for the interaction of these three quantities, when the energy exceeds the appropriate value, the melting amount of the plastic is large and the welded material is easily deformed, if the energy is small, it is not easy to weld firmly and the applied pressure cannot be too large,so, the best combination is to find the proportional scale

Contact Us

Cross Flow Fan Blower Assembly Welding Ultrasonic Welder is used for bonding impeller blade in assembling tower fan, because of the whole legnth is combined sect by sect in laminated welding one by one, ultrasonic welding pressure must be applied in each cycle pressing-down, our machine adpots rolling screws and linear guiding movement to ensure the precision welding position, so the bottom servo-motor driven clamping device is specified configuration for this exclusive achievement, it is better to present sample picture with welding diameter and height of your cross flow fan for tech verification prior to proceeding with solution, we are always ready for your consultation, please don't hesitate to contact us to find what can we do more for your production

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader