Rotary Friction Welder Plastic Spin Welding Machine of Frictional Rotation Fusion Equipment for Nylon_PP_PE Circular/Round Parts

Rotary Friction Welder Plastic Spin Welding Machine

Rotary Friction Welder Plastic Spin Welding Machine includes rotating one parts, also named driving actuator in continuous circular motion against another fixed part, name fixture, under axial force, in all thermoplastic spin friction welding processes, the heat generated by the frictional action must be sufficient to melt and flow the plastic at the weld interface, sufficient heat is generated by a combination of welding time, welding force and interface velocity, determined by rotational motion

Product description

Rotary Friction Welder Plastic Spin Welding Machine

Mainly introduction | |

Rotary Friction Welder Plastic Spin Welding Machine is a frictional welding technique capable of producing strong, air-tight welds in thermoplastic parts with a circular-axis joint. In this process, friction occurs by rotational motion controlled by either a servo electro-magnetic or pneumatic powered motor or motor control system which regulates the RPM (Revolutions per Minute) and motion control of the system | |

Mainly application | |

PP/PE/PVC/nylon filter/water filter/medical filter/oil filter/cup welding and any other circular/tubular shape plastic parts welding to get water-proof and air-tight welding effect, Auto & Motorcycle Filter, Auto & Motorcycle Filter, RO water purifier filter, Water jug and round work pieces | |

Character | |

Ability to weld parts with circular joint that are not easily welded by ultrasonic. Relatively fast cycle times when compared with other methods. Compatible with most thermoplastics Ideal for welding of PP and PE material Ability to weld several dissimilar materials. No consumables, fumes or emissions. High strength, hermetic welds are typical. Heat confined to weld interface. Easily automated. Low cost, quick change tooling. Low maintenance. Low power consumption. | |

Parameter | |

model | KLP-2P/3P |

System control | PLC |

Maximum diamter | D:300mm/500mm |

Power | 1 Phase 220 V/380 11A/3P |

Dimensions | L750mm*W800 mm*H1950mm |

Net Weight | 400 Kg |

Servo Motor | Heating Evenly |

Air pressure | 5kgs/cm*cm |

capacity | 10-15pcs/min |

power | 2P/3P |

MFR: KEEPLEADER™ have modified and designed Rotary Friction Welder Plastic Spin Welding Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated detailsNote:

Please tell us following information:

❶The material and definite size of the product;

❷ 3D drawing if you have;

❸ It's better if you can send us the picture of workpieces or sample

Product uses

Rotary Friction Welder Plastic Spin Welding Machine is used to weld thermoplastic parts with rotational symmetrical joining surfaces, its joints must be circular, cylindrical, tubular, round and spherical shaped interface to apply rotational friction, the welding of the two halves in one part is due to the simultaneous application of rotation and axial pressure, thus, the friction obtained generates the heat necessary for their welding and fusing, Rotary Friction Welder Plastic Spin Welding Machine is ideal for PP, Nylon,PE,Polyester and any other semi-crystalline material which is much more difficulty to weld by ultrasonic, and its bonding result in air-tight and water-proof

Function illustration

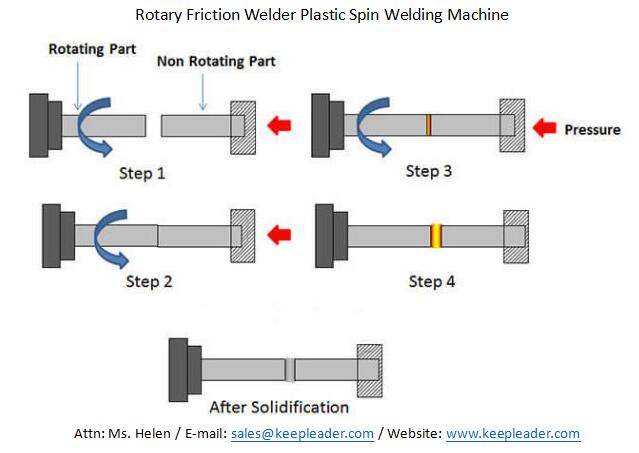

Rotary Friction Welder Plastic Spin Welding Machine has simple process, but produce air-tight, water-proof joints, in 1st, the parts of the two halves are brought together and axial force is applied, the inter-facial friction begins but initially, no material flows, in 2nd, the welding zone material starts to melt and material displacement to the edge of the weld begins, in 3rd, the process is a steady state phase, the material is pushed out from the weld at a constant rate, in 4th, the process is the cooling phase when the inter-facial friction is stopped but the force is still applied to consolidate the active bonding, an alternative to welding by time is to weld by displacement, inter-facial friction is applied to components being welded until a fixed material displacement is achieved, this would typically 1 to 2mm, but would depend on the flatness of components being welded, undulation in the welding interface would need to be taken into consideration when setting the weld displacement

Rotary Friction Welder Plastic Spin Welding Machine must equip with custom spindle, also named driving actuator and holding device/pneumatic fixture, or named stationary base, whatever their shape and size are precision CNC machined, also add elastic rubber inside of cavity to apply axial pressure and downing displacement during rotational friction, our technical team will work with injection mold samples to work out a prototype for your confirmation prior to production, the cosmetic appearance after welding is also our endless pursuit

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader