Round Plastic Assembly Rotary Friction Welding Spin Welder of Circular Pipe_Tube_Mug_Barrel_Cup_Cartridge Filter Spinning Welder

Round Plastic Assembly Rotary Friction Welding Spin Welder

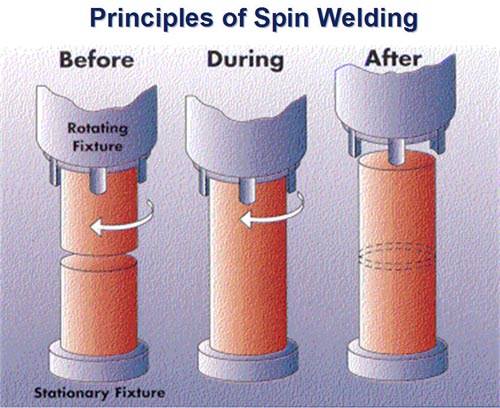

Round Plastic Assembly Rotary Friction Welding Spin Welder is a method of joining plastic components together with surface spinning friction concentrated in a circular weld joint, one part is spun relative to another, the pressure is applied, causing the melted material displacement, the spinning process stops and the parts continue to be pressed together while they bond in a holistic utility,hermetic seals are also attainable depending upon the materials used and the weld joint configuration, while spin welding works with all thermoplastics and can accommodate virtually any diameter part, it is particularly suited for crystalline resins such as polyethylene and polypropylene

Product description

Plastic spin welding gun | |

Mainly introduction | |

Round Plastic Assembly Rotary Friction Welding Spin Welder is a frictional welding technique capable of producing strong, air-tight welds in thermoplastic parts with a circular-axis joint. In this process, friction occurs by rotational motion controlled by either a servo electro-magnetic or pneumatic powered motor or motor control system which regulates the RPM (Revolutions per Minute) and motion control of the system | |

Mainly application | |

PP/PE/PVC/nylon filter/water filter/medical filter/oil filter/cup welding and any other circular/tubular shape plastic parts welding to get water-proof and air-tight welding effect, Auto & Motorcycle Filter, Auto & Motorcycle Filter, RO water purifier filter, Water jug and round work pieces | |

Character | |

Ability to weld parts with circular joint that are not easily welded by ultrasonic. Relatively fast cycle times when compared with other methods. Compatible with most thermoplastics Ideal for welding of PP and PE material Ability to weld several dissimilar materials. No consumables, fumes or emissions. High strength, hermetic welds are typical. Heat confined to weld interface. Easily automated. Low cost, quick change tooling. Low maintenance. Low power consumption. | |

Parameter | |

model | KLP-3200 |

System control | PLC |

Maximum diamter | 250mm |

Power | 1 Phase 220 V/380 11A/3P |

Dimensions | L750mm*W800 mm*H1950mm |

Net Weight | 400 Kg |

Servo Motor | Heating Evenly |

Air pressure | 5kgs/cm*cm |

capacity | 10-15pcs/min |

power | 3200w/2600W |

MFR: KEEPLEADER has modified and designed Round Plastic Assembly Rotary Friction Welding Spin Welder to accommodate our customers’ unique and special requirements, pls contact KEEPLEADER for tech assessment with your app.

Detailed Images

Round Plastic Assembly Rotary Friction Welding Spin Welder is the preferred bonding technique for thermoplastic components assembly with a circular axis joint which have bond strength/hermetic requirements, during spin frictional welding, one half is held stationary in a holding fixture while the other half is rotated against it under axial loading pressure at specified velocity, this resulting friction causes the joining surface to melt and fuse together, producing strong hermetic welds

Machine Uses

Round Plastic Assembly Rotary Friction Welding Spin Welder enable thermoplastic parts with spherical joining engagement to melting displacement to achieve assembling process, particularly for welding object made of Semi-crystalline, likely Nylon, PP,PE that are not easy welded by ultrasonic vibration, in addition, this Round Plastic Assembly Rotary Friction Welding Spin Welder obtain preference with its advantages, such as relatively fast cycle times when compared with other methods; compatible with most thermoplastic;ideal for welding of PP,Nylon, PE materials; ability to weld several dissimilar materials;no consumables, fumes and emissions; high strength, hermetic welds are typical; heat confined to weld interface; easily automated;low cost,quick change tooling; low maintenance; and low power consumption

Function illustration

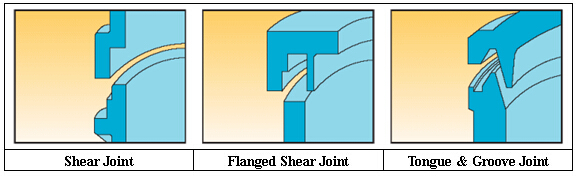

Round Plastic Assembly Rotary Friction Welding Spin Welder produces a welded joint, in many cases, yields a weld strength that is consistently equal to or stronger that any other area of the part, as a result, the weld are can most often to expose to the same strains and stresses as any other area of the part, however, the spin welding joint design roles a predominant performance resulting in cosmetic appearance, and bonding strength, likely, trap flowing-material into groove, design a step to stop melting displacement, design rise or relieve grip to engage the driving actuator and joints should also provide sufficient part-part alignment

FAQ

How can I buy good quality Round Plastic Assembly Rotary Friction Welding Spin Welder

Firstly: with on line or email conversation, to check the supplier is professional or not, if the supplier has ever supplied the similar machines to other buyer, will be better, don’t save time on studying, don’t stop asking questions before order, more time and efforts you spend, more you can get on the purchasing

What is the auxiliary equipment for Plastic spin welding gun machine?

It need one air compressor and necessary tooling, KEEPLEADER ™ can also make the tooling according to your welding products, the buyer need to provide samples and 3D drawing

I never use Plastic spin welding gun machine before, how can I operate it?

For small machine, under 10kw, it is easy, KEEPLEADER ™ will provide user manual and train video, also have on line service to resolve any problem

For big machine, example: 50~100kw, Engineers of KEEPLEADER ™ will come to your country, help to install the machine, and train your workers. Buyer also can come to China 1~2 days for necessary Factory training before shipment

Does KEEPLEADER also makes the tooling?

Yes, KEEPLEADER ™ has tooling department, can do customized, please provide samples and 3D drawing of igs format after order

What information does buyer need to provide in advance?

Please let KEEPLEADER ™ know, 1: material, 2: thickness, 3: size of your products, 4: sample picture, 5: purchasing budget

Does KEEPLEADER has messenger for on line service

Skype: keepleader

Whatsapp:+86 13590415784

How long is the warranty time?

One year

Contact Us

Round Plastic Assembly Rotary Friction Welding Spin Welder assorts an reliable plastic assembling approach for spherical shaped engaging joint with constrained rotary friction, regardless of the application, engineer are well-advised to contact welding equipment supplier as early in the joining design process,preferable before any molds are cut, this collaborative approach can help manufacturers work through any design constraints and create the ideal joint design,keepleader, we are clients orientation thought, we partner with the end-user to find the best plastic joining solution, additionally, w are application experts with the versatile portfolio of plastic jointing, sealing, and we can select the best technology for your application,kindly consult your individual plastic assembly process with our engineering expert to find what more can we do for you

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader