Portable Plastic Spot Welder Ultrasonic Manual Welding Machine of PP_PE_ABS_EVA_Fabric Sealing Handheld Mini Ultra Sonic Sealer

Portable Plastic Spot Welder Ultrasonic Manual Welding Machine

Portable Plastic Spot Welder Ultrasonic Manual Welding Machine has the same ultrasonic tech of fictional rubbing melt in thermoplastic bonding, shaping, when ultrasonic wave acts on the plastic contact surface, it will produce tens of thousands of times of high frequency vibration per second, this high frequency vibration reaches a certain amplitude, through the upper welding parts, the ultrasonic energy is transferred to the welding area, and because of poor thermal conductivity of the plastic, it an not be distributed in time and gathered in the joining area, which causes the contact surface of two plastic to agglutinate rapidly, after apply a curtain pressure, it will be fused into one, either or the extended profile shaped, when the ultrasonic wave stops action,let the pressure continue for a few seconds, so that it will solidifies and forms, so as to form a strong molecular china, to achieve the purpose of welding, the welding strength can be close to the strength of matrix material

Product description

Mainly Application | |

Portable Plastic Spot Welder Ultrasonic Manual Welding Machine is used for Spot welding, riveting, screw imbedding, appliqué welding, often used in the field of stationery industries, consume electronics industry and electronics industry | |

Introduction of Ultrasonic handhold welder | |

Portable Plastic Spot Welder Ultrasonic Manual Welding Machine is applied for plastic welding process, like, ultrasonic ABS welding, ultrasonic Acrylic welding, ultrasonic PVC and ABS welding, ultrasonic PA welding, ultrasonic PC welding, ultrasonic PE welding, ultrasonic pp welding, ultrasonic PE welding, ultrasonic PP welding, ultrasonic PS welding, ultrasonic PVC welding. | |

Characteristics | |

1.Proprietary anti-corrosion technology, even in the harsh acid salt (such as electroplating factory) working environment, the service life of up to ten years. | |

Advantages | |

1:low power consumption, firm welding, low noise, small-sized, dust-proof, high performance 2:automatic frequency-tuned system: take PLL for the ultrasonic circuit control 3: with pedal switch to convenient control 4: compacted, space-saved, convenient to transport | |

parameter | |

Model | KLC-3028/KLC-5028/KLC-8028 |

Power | 300w,500w,800w |

Voltage | 220V/50Hz 110V/60Hz |

Output Frequency | 28kHz/35kHz/40kHz |

Cohesion Specification | 1-15mm |

Cooling mode | Fan cooling |

Working mode | Separated excited |

Volume | 268*168*198mm(L*W*H) |

Net weight | 7.5KG |

Gross weight | 10kgs |

Note: The parameter herein stated is manually measured, the actual machine has possibility in little difference, if have crucial demand in its application, please double check with our sales, only paper confirmed will be regarded as contracted obligation

Detailed Images

Portable Plastic Spot Welder Ultrasonic Manual Welding Machine transfers options of handgrip between straight probe and pistol,that depends on end-users practical assembling process, compact designed ultrasonic generator features lightweight and maneuverable for easy of use, that additionally saves time, energy and money on utilities,tailored tip of ultrasonic horns gratify versatile assembling scenarios

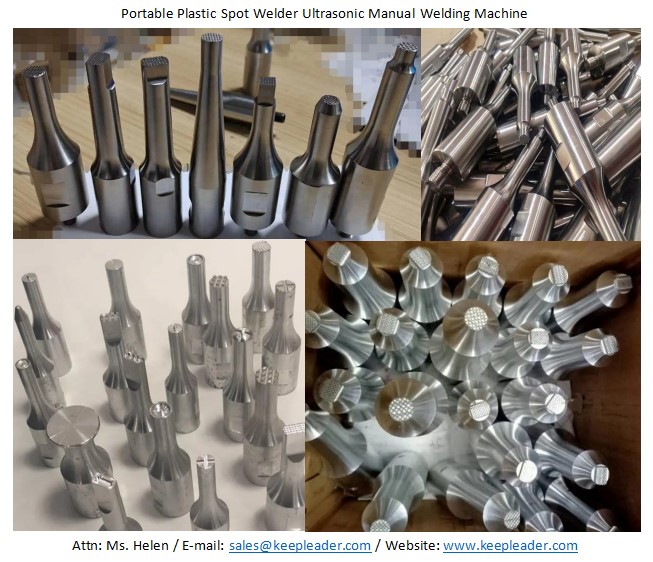

Tailored Acoustic Tools

Portable Plastic Spot Welder Ultrasonic Manual Welding Machine executes thermoplastic melting for assembling process by changing the ultrasonic sonotrode/horn,such as Mosaic,riveting, spot welding, pressure welding, inlaid,swagging,hence, the users are requested to advise us their preferred welding head for our customized construction, such as toothed head, square head, round shape, other specifications to comply with versatile assembling process

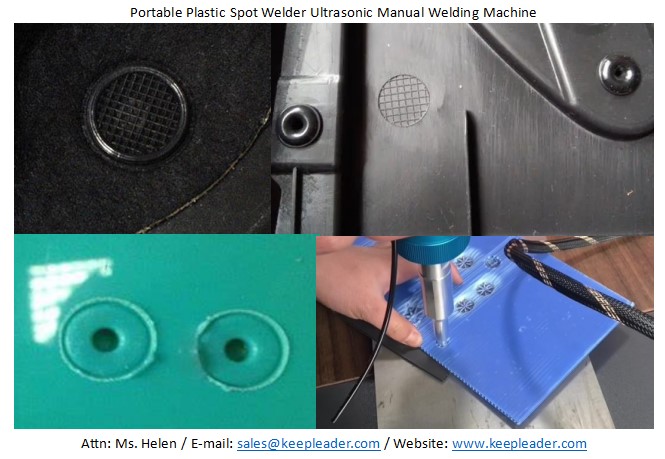

Machine Uses

Portable Plastic Spot Welder Ultrasonic Manual Welding Machine composes three parts of ultrasonic generator, ultrasonic transducer stack and acoustic tool, ultrasonic generator can converter electric current to high frequency signal, and continue to produce mechanical vibration per ultrasonic transducer stack, and acoustic tool execute the ultimate process of sharp vibrating friction between welding tip and melting surface, caused the plastic body joint surface between “plastic flow of material instantaneous agglutination process”Portable Plastic Spot Welder Ultrasonic Manual Welding Machine is suitable for ABS,PP,PE,PC,PMMA,PS,PETG,APET,Acrylic and other thermoplastic in industrial assembling process, such as spot welding, pressure welding, riveting, cutting, screw embedding, swagging, boarder flower, dot marking, sealing, applique welding, and other processes, gain popularity in shopping works and industrial production, likely electronics, electrical appliance, automobile, auto parts, packaging, environmental protection, medical,non-woven clothing, stationery daily necessities, plastic toys, sporting goods, communication equipment, PP,PVC manure belt, bumper, soundproof cotton, waterproof board, mark non-woven cloth, nylon fabric film, fishing rod box and other industries assembling process

Contact us

Portable Plastic Spot Welder Ultrasonic Manual Welding Machine is used in numerous manual assembly operations to bond, reshape, or mold thermoplastics, typically used as a handheld plastic spot welding, this ultrasonic spot welder is found in industries including consumer goods, electronics,and staking, kindly unveil your operational sample photo for tech audit prior to construct our tailored ultrasonic horn

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader