Cable Splicer Bonding Wire Harness Welder Ultrasonic Metal Welding Machine of Aluminum_Copper Wiring Terminals Ultrasound Bonder

Cable Splicer Bonding Wire Harness Welder Ultrasonic Metal Welding Machine

Cable Splicer Bonding Wire Harness Welder Ultrasonic Metal Welding Machine holds high regard as a crucial jointing technology of conductive materials, it comes with a few advantages compared to conventional welding methods such as gas metal, arc welding and inverter welder,such as ultra fast: the entire process lasts for mere split seconds;precise: ultrasonic metal welding focuses spot -on, a vast number of welding parameters ensure precise and reproducible results, this is particularly vital for welding the smallest metal parts, for example in battery tabs;cost-efficient:no other additives such as solder or any other chemical agent required; environmentally friendly: very little energy is consumed and no chemicals are used;characteristic: ultrasonic metal welding ensure a high degree of strength and excellent electrical conductivity at the joined parts;gentle: the metals are not damaged or deformed apart from the weld spot;safe:no sparks or smoke are generated during ultrasonic bonding process

Product description

Ultrasonic Metal Spot Welding Machine for wire harness, braided wire welding | |

Mainly application | |

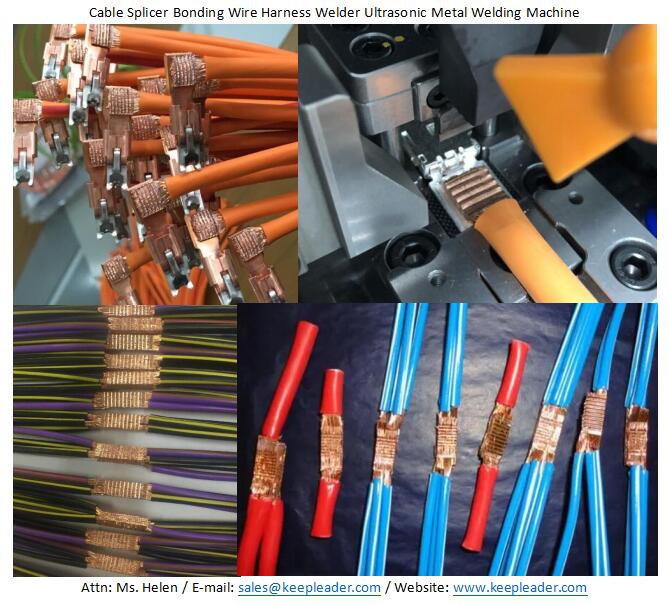

Auto Wiring Harness Motor relay sheet sealing in the bottom of copper tube carbon brush sheet welding 0.10mm nickel tab with 0.018mm copper foil(40-80 layers); individual spot welding area is 4*4mm; 0.10mm aluminum tab with 0.018mm aluminum foil; this is between 50-100 layers. Standard: Two metal ions infiltrate each other; do test depend on the pulling | |

Character | |

Imported piezoelectric ceramic, ultrasonic output stable and smooth High power ultrasonic generator Digital interface, easy to operate special steel rods become vice imported steel welding head, durable linear guide with high quality and ensure stable movement of welding head may be replaced, for a variety of processes | |

Mainly parameter | |

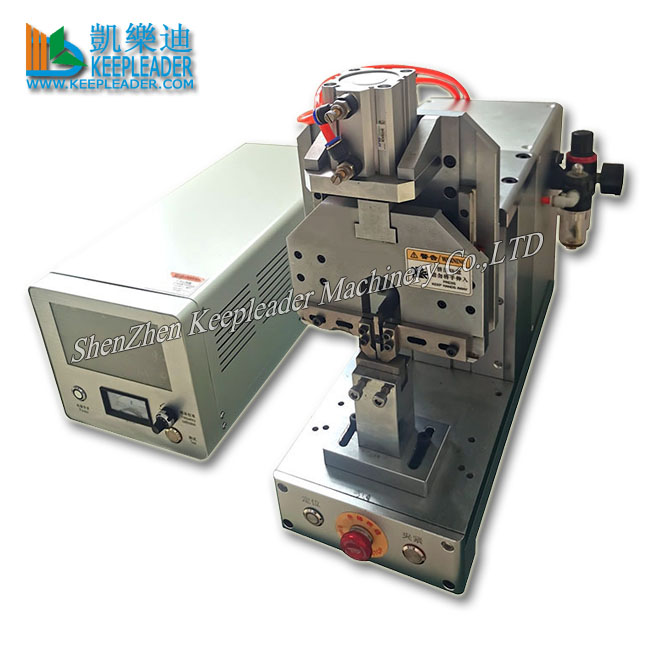

Name of machine | Cable Splicer Bonding Wire Harness Welder Ultrasonic Metal Welding Machine |

Model | KLM-3200 |

Frequency KHz±1KHz | 20khz |

Voltage | 380V three phase four-wire |

Weight | 60kg |

Max Input Power VA | 3200 |

Air pressure | 2-10kg |

Time control | Less than 2S |

Thickness available | With in 5mm |

Material available | Copper, Aluminum, Nickel, Silver |

Main components | |

The whole machine including: Main frame, transducer system, head, ultrasonic generator, power switch, power indication lamp, working indication lamp, output indication lamp, frequency measuring system, pneumatic system, computer panel control output power, welding, holding, etc | |

Cable Splicer Bonding Wire Harness Welder Ultrasonic Metal Welding Machine essentially causes metal wires to become so plasticized that the molecules of both layers end up mixing together, we call this process “molecular displacement” as well, that the different layers become intermixed, when the tool/ultrasonic horn completes withdraw, the single solid piece reaches completion, as opposed to two separate ones, thanks to the molecules being forced into forming new bonds with each other, in addition, the amount of power required for creating this type of cold metal welding, dry bonding is much less that a traditional welding system. Which leaving a stronger weld as well, for these reasons and many more, Cable Splicer Bonding Wire Harness Welder Ultrasonic Metal Welding Machine can be the ideal solution for may kinds of bonding application in conductive material, such as wire harness, wire splicing, terminal wire, battery tab and metal foil layers for battery poles and other more

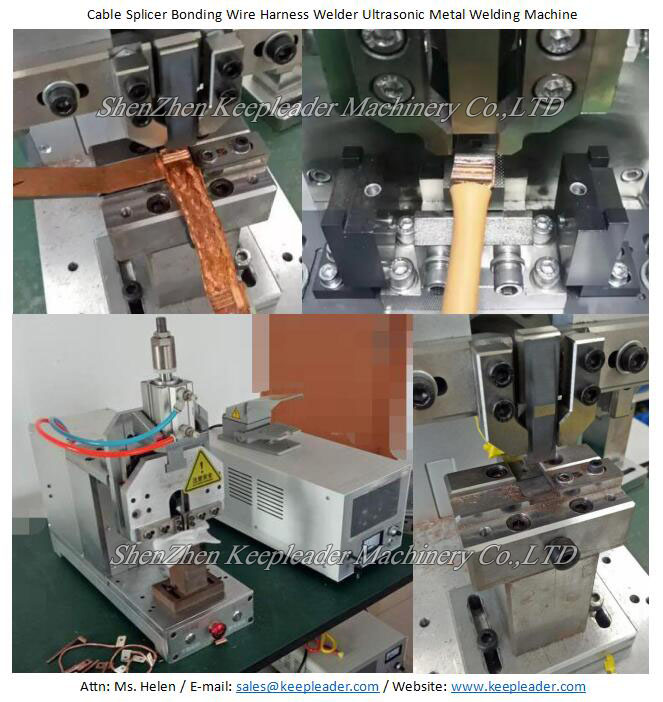

Detailed Images

Cable Splicer Bonding Wire Harness Welder Ultrasonic Metal Welding Machine consists mainly four elements,ultrasonic generator,ultrasonic vibration stack and intelligent controlling system, the ultrasonic generator provides a high frequency amplitude,that is then transformed into ultrasonic vibration stake resulting in mechanical oscillation via its converter, there is another component called amplitude transformer/ultrasonic booster changes the amplitude of vibrations, the ultrasonic horn/sonotrode can do this as well, the entire ultrasonic bonding process involves versatile parameters,that gain intelligent controlling, its main task attributes to introduce the energized ultrasonic into the top of the metal surface horizontally, the ultrasonic causes it to move while the anvil/Fixture holds the bottom of the metal object in localization,molecular vibration rubbing happen here, the roughness peaks of metal are rubbed off, the top layer of oxidation, either or electroplates are broken up and the metal completes plasticity, now, the applications can be joined with them melting, this is perfect for welding thick metal, films and wires

Product uses

As a reliable supplier in Cable Splicer Bonding Wire Harness Welder Ultrasonic Metal Welding Machine,keepleader, we deliver proven performance and quality,our ultrasonic metal welding machines gain sophisticated bonding process in conductive materials of applications such as wire spicing, wire termination, battery tabbing, cable processing, seam welding, copper/aluminum tube end sealing and cutting,keepleader provides the industry’s latest innovation for welding conductive metals, such as copper, aluminum, nickel, silver and more, we additionally offers a complete line of ultrasonic metal welder, tooling and fixtures

Contact Us

The users benefit from the advantages of Cable Splicer Bonding Wire Harness Welder Ultrasonic Metal Welding Machine in connection of conductive material,likely high strength,no losses in conductivity,short cycle time,particularly gentle on metal surface,low energy consumption,permanent process monitoring, to ensure end-users’ success, keepleader, we advise every steps of procurement with decades of ultrasonic experience from first sketch to the development of the application to process optimization and beyond,we can solve your application quickly, reliably, and economically, and respect every initiation whatever enquiry or consultation, please contact us without any hesitation

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader