Pneumatic Hot Stamping Machine for Plastic Rubber Indenting_Leather Embossing_Wooden Branding_Paper Gilding Heat Press Imprinter

Pneumatic Hot Stamping Machine

Using Pneumatic Hot Stamping Machine has two definite advantages when compare to using a manual unit, the first is consistency: each and every imprint is made with exactly the same amount of downward pressure and dwell time, once the appropriate combination of pressure and dwell time are determined, the operator can be assured that every imprint will be precisely the same as his and her previous imprint, the second advantage is speed, hot stamping operations can be completes as quickly as the operator can insert the item to be imprinted and press the activation buttons, these Pneumatic Hot Stamping Machine can complete the job in half time required for manual hot stamping unit, digital controlling system is utilized throughout Pneumatic Hot Stamping Machine for temperature control, dwell-timing and pressure, all of our Pneumatic Hot Stamping Machines have a number of unique features, including lubrication-free cylinder and valves, adjustable air-flow control, air exhaust-mufflers for quiet operation, regulator with pressure gauges for incoming-line pressure and working pressure, and separate electric air-activation switch, the low volume of air consumption allows any unit to be operated with small, inexpensive air compressor, which we can provide if you do not have one, all electric and pneumatic controls are arranged in a compact manner for easy use

Product description

Pneumatic Hot Stamping Machine

Mainly Application | |

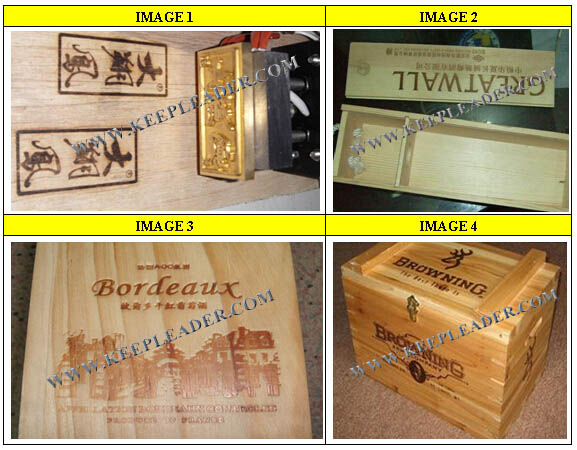

Pneumatic Hot Stamping Machine is used for logo, trademark, Serious Number, production date in printing by hot stamping technology, also used for hot pressing, hot welding, hot sealing, hot embossing, hot impressing, hot forming, hot stamping, Available material: Plastic, rubber, solid wood, cable, wire, Chinese chess, leather, bamboo and etc, which are made of various commodities | |

Character | |

Microprocessor control and pneumatic component drive for easy operation Flat and cylindrical shape stamping both are available Manual/semi-auto/auto operation available With function of foil winding and foil collecting Stamping pressure/temperature/speed all adjustable Structure solid and durable Pneumatic driven is durable and stable in movement No impact during the working to guarantee the stamping effect Two buttons triggered to run for safety purpose Assembled the pedal Switch for convenient operation Have function of self-counting in outputting | |

Mainly parameter | |

Model | KLS-1800 |

Heating plate size | 150*210mm |

Working plate size | 170*220mm |

Pressure | 100-500kgs |

Maximum pressure | 800kgs (made-to-order) |

Stamping Stroke | 300-500mm |

Max. Work piece height | 200mm |

Piston Diameter | 63-125mm |

Air pipe | 3/8PT |

Air consumption | 10L |

Net Weight | 180kgs |

Heating power | 1800w |

Power | 110/220V 60/50Hz |

Max. Printing speed | 1000 PCS/hr |

Stamping pressure | Within 800kgs |

Pneumatic Hot Stamping Machine accepts customized construction, likely dimensional fram, specified engraved die and controlling system and driving device

Detailed Images

Using Pneumatic Hot Stamping Machine attains advantaged elements, such as No.1:free hands, and height efficiency because of air operated pneumatic driven activator with foot switch and every hot stamping work can be finished within 1~3s;No.2: simple and easy operation, the journey of stamping head accept freely-adjustment, the mounting plates designate sufficient space to mount the stamping die/mould;No.3: Excellent stamping effect, the stamping pressure up to 500kgs, four column sliding activate downward plump to distribute uniform pressure without uneven indenting imprint, and its travelling speed, dwell-time and applied pressure are all in digital control;No.4: with counting and clearing function, display of set temperature(SV) and real temperature (PV);No.5: big working table with adjustable mounting slot for accurate position

Product uses

Pneumatic Hot Stamping Machine assist you on adding value to your production in imprinting decoration,hot stamping is a dry imprinting method that delivers clean and consistent images on parts of all sizes with various geometries and textures, the print require no solvent, hence, no drying time and provides a high-quality, accurate and durable image, our Pneumatic Hot Stamping Machine also include heat staking, heat transfer and hot foil gilding on plastic, paper, wooden and leather, automatic foil roll feeding and rewinding device can integrate into Pneumatic Hot Stamping Machine to complete foil gilding process, when the preheat engraved die contact the printing object with golden foil sandwiched, the marking foil deposits onto the substrate, the foils consists of three layers, a color layer that contains a metallic or pigment dye, an adherence layer that provides a lasting bond, and release layer that allows the die to be pulled away,the foil is pinned between the hot die and substrate for a certain amount of time, known as dwell time, when the dwell time is sufficient, the press release the pigment layer, which binds to the work-pieces, substrate with heat and pressure when contact is made with the die

FAQ

01: How do I get the best Pneumatic Hot Stamping Machine?

For hot printing, there are many differences,the usually modes has hot branding, foil hot stamping and heat transferprinting, So, you need to tell keepleader your expected printing effect, it isbetter to show an existed samples, our sales representatives will make acorrect recommendation with your description, pictures

02: Can keepleader make printing tools of thismachine?

Yes, as your request, keepleader can makeprinting die and fixture in need, if you have artwork, please send to us, or,you can tell us your explicit application, we also can design artwork for youconfirmation before production,

03:Do I need other device or material in using this machine?

Thismachine can print the wood case by hot branding, you don’t need aluminum foil,but, your factory must have air compressor, because this machine has pneumaticactuator, you don’t need any operate this machine

03:What material of products can be printed by this machine?

Allof thermo material can be printed, for example, bamboo, plastic, wooden,rubber, paper box

04:Can this machine damage my box?

No,because, keepleader will study the geometry structure of your parts to designfixture, only the printing area bear the pressure, the printing temperature andpressure also are precision-controlled

05:what about the warranty?

Allof our machine has one year warranty, during the warranty time, keepleaderprovide free parts to replace the defects, we also can arrange our engineer toprovide service to your factory, for oversea clients, we can provide remotetraining by drawing, video, and on-line communication

06:Are you trading company or manufacturer?

Keepleaderis a manufacturer from design to build,

07:How long is your leading time?

Forstandard model, our leading time is 5~ 10 business days, but, need more timefor customized in large quantities

08:How about terms of payment?

T/T.30% Deposit, the balance before delivery, or you can pay us from our on-lineshop

09:Does keepeader accept OEM order?

Certainly, please try to confirm the detailsbefore orderContact us

Pneumatic Hot Stamping Machine has compact structure but, sturdy construction and, applied for heat impression mark, if you cannot find your concerned features, or you have other exception consideration for your individual production, please contact our experienced sales preventatives to find what more we can do for you

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader