PCB Cleaning Ultrasonic Vibration Cleaner for Circuit Board_Motherboard_SMT Cleaning Ultrasonic Scrubbing Megasonic Bath Cleaner

PCB Cleaning Ultrasonic Vibration Cleaner

PCB Cleaning Ultrasonic Vibration Cleaner is accomplished through the rapid formation and collapse of minute bubbles or cavities in a liquid, this phenomenon is called cavitation, it offers intense mechanical agitation combined with enhanced chemical activity, power circuit board that would ordinarily require intense hand scrubbing can often be cleaned in a matter of seconds with Ultrasonic Vibration Cleaner,PCB Cleaning Ultrasonic Vibration Cleaner should be considered in applications where contaminants may be lodged in crevices, or where ultra-clean results are necessary, its laborsaving advantage make it the fastest, most economical way to clean PCB and any other immersible electronic components

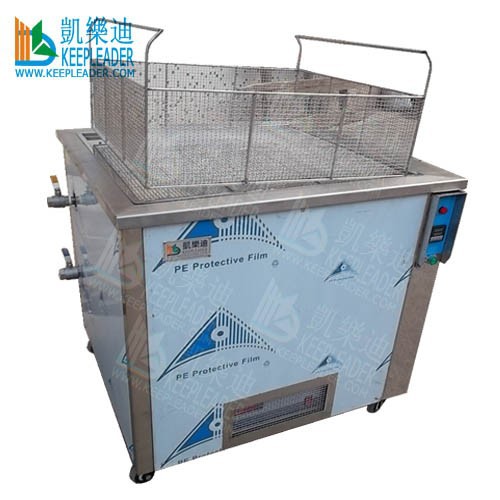

Machine description

Printed circuit board ultrasonic cleaning machine

How to use an ultrasonic cleaning to restore electronic and PCBs

Dust, dirty and corrosion can impact the performance of printed circuit boards (PCBs) used in electronic equipment exemplified by sophisticated hand-held devices such as iphones, some of which have been accidently dunked, can be restored, KEEPLEADER is suggesting to use ultrasonic cleaning along with ultrasonic cleaning solution expecially formulated for delicate electronics

Selecting an ultrasonic cleaning machine

Ultrasonic cleaning machine, such as the tabletop, stationary series are ideal for small volume user in cleaning or used as household device, KEEPLEADER can make to size and make customized function, e.g: heating power, timer, counter, temp display, resetting, cycling and filtering mounted and etc, the multistage ultrasonic cleaning machine is recommended for big factory, manufacturer. For them, KEEPLEADER will consider the automatic loading, unloading and transmit among cleaning process, as well as drying system, water purification auxiliary

How to select and use the cleaning solution

The wrong cleaning solution, just as the wrong ultrasonic cleaning frequency, can do more harm that good, an ultrasonic cleaning solution ideal for glass and ceramic substrates, optics, PCBs plastic parts is the biodegradable concentrate detergent, is removes grease, oil, activated fluxes, dust, fingerprints, light corrosion and residues from coffee, tea, colars, milk and other sources

Depending on the extent of contamination this concentrate is diluted 3% to 10% with water, the recommended ultrasonic cleaning time is 3 to 10 minutes at approximately 65C/150F, after cleaning the parts, must be rinsed in distilled or deionized water, this is very important in order to remove any traces of cleaning solution residue, because tap water also will leave residue deposit, it must not be used as a rinse, dry the components thoroughly before reassembly

Note, that these are only guidelines of KEEPLEADER, the user should consult with the ultrasonic cleaning professionals at KEEPLEADER regarding equipment, solution and procedures to meet your requirements

Other suggestion from KEEPLEADER

A fresh batch of ultrasonic cleaning solution contains entrapped air, you can see evidence of this by the bubbles that appear on the inside of a glass of water standing at room temperature, this air interferes with the cavitation process and must be driven off before you begin the cleaning operation to do under steps;

01: add water and correct portion of cleaning concentrate to the tank’s fill line

02: set the temperature dial

03: turn on the ultrasonic cleaning to start the degassing operation

The rising temperature coupled with the cleaning chemicals and ultrasonic energy will speed the degassing operation and at the same time thoroughly mix the contents of tank, when air bubbles not longer rise to the surface, you are ready to clean the parts, place them in the mesh basket, taking care to keep them from contacting each other, lower the basket into the basket into the cleaning solution and set the timer, as you become experienced with ultrasonic cleaning PCBs and other electronic components, you will become more proficient and efficient, the engineer at KEEPLEADER are ready to help you reach this goal by selecting the ultrasonic cleaning model, frequency, power, cleaning solution, cleaning process that meets your requirements

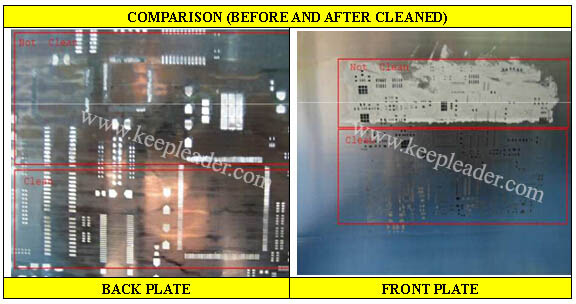

Cleaning effect

PCB Cleaning Ultrasonic Vibration Cleaner is used for power circuit board, and other immersible electronic components cleaning by ultrasonic agitation informed tiny bubbles blusting and jetting to remove the embessed and lodged into the blind, and hard-to-reach area

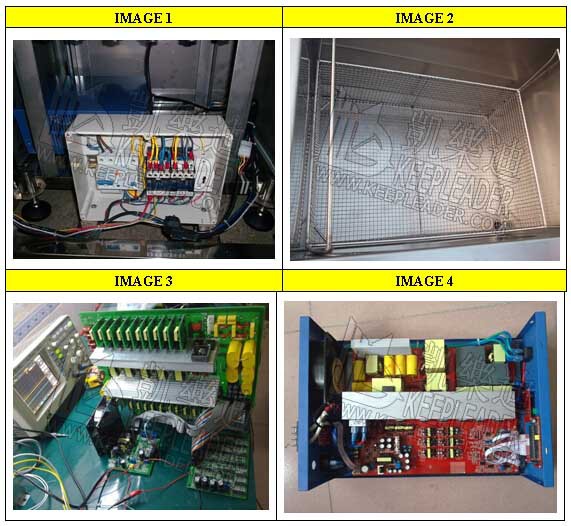

Detailed images

PCB Cleaning Ultrasonic Vibration Cleaner has three basic elements are required to produce cavitation: a generator, a tank, and a transducer, this combination of components produces an ultrasonic system, the intense agitation needed for cleaning occurs when standard electrical current is converted first to electrical energy of a higher frequency by the generator, then into ultrasound wave by the transducers, these transducers are either bonded to the tank bottom, or enclosed in a stainless steel housing which is mounted inside of tank, the sound waves produced by these transducers exert enormous pressure which loosen flux, wax, particles, debris lodged in hard-to-reach areas of power circuit or other electronic components, including blind holes and crevices

Contact Us

KEEPLEADER, we dedicate to offer customized PCB Cleaning Ultrasonic Vibration Cleaner in its size,function and configuration,please let us know more concerning your preferrable terms for tech verification prior to quotation

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader