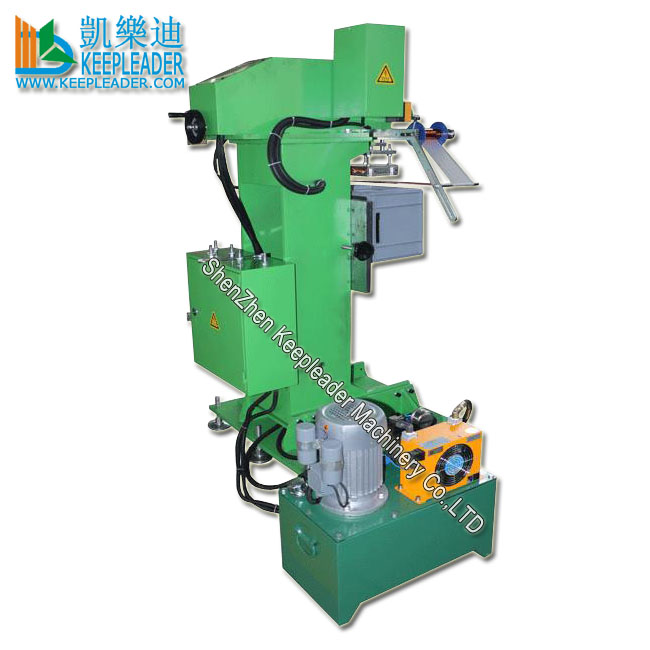

Hydraulic Hot Foil Stamping Machine for Plastic Crates Paper Boxes_Storage Containers_Cases 20 Tons Press Gilding Heat Imprinter

Plastic Crate Heat Press Bronzing Hot Foil Stamping Machine

Hydraulic Hot Foil Stamping Machine for Plastic Crates is designed for gold blocking logo, text, sign, identification codes, graphic image, and serial number onto the surface of small, medium size of plastic turnover box, crate, basket, container and case, it is is the new generation of multi-functional crates gold foil stamping machine, fitting for both flat stamping and for different sizes of crates’ surface gliding the nose vertical adjustment structure, adjustable vertically to solve a variety of mold installation difficulties, and truly realizing of one stamping machine freely arrange versatile production in shape and size

Product description

01: Application

Hydraulic Hot Foil Stamping Machine for Plastic Crates take specified construction, that designs extended tongue to form three-sided suspended structure, hence, the plastic containers with deep hollow can stop into the stipulated working position after precision alignment, which not only save the space of the machine, but also improves the quality of bronzing process, Our Hydraulic Hot Foil Stamping Machine for Plastic Crates adopts hydraulic actuator, that can apply durable, consistent, and robust pressure results in crisp and squeaky bonding performance, typically for versatile cans, boxes, containers, crates and basket made of solid plastic and paper with large Gliding area, Hydraulic Hot Foil Stamping Machine for Plastic Crates often appears in gliding fields in versatility, such as: paper gilding, leather impression, wood ware basking; paper concave-convex embossing, cloth hot stamping; plastic bronzing; woodiness object basking and impress; leather bronzing and molding, paper products concave indentation, and die-cutting

02: Parameter

Name | |

Type | KLS-2129 |

Heating Power | 3800w |

Power Supply | 110v,60hz or 220v,50hz |

Hot Plate Area | 310*290mm |

Working Table | 480*600MM |

Max printing pressure | 20tons |

Stroke Distance | 100mm |

Foil In Feed | Motor Drive |

Temperature Adjustment | 0~300 degree |

Gliding Speed | 600~800pcs / Hour |

Max Loading Height | 1300mm |

Max Loading Depth | 500mm |

Working Control | Pedal Valve |

Safety Control | Laser-Sensor Lighting-gate (optional) |

Hydraulic System | 46# Oil |

Packaging Size | 1.1*1.11.9m |

Gross Weight | 800kgs |

03: Advantages

Advantages of Hydraulic Hot Foil Stamping Machine for Plastic Crates

Efficient and effective: compared with pneumatic devices, the hydraulic system can quickly and accurately complete the travelling of stamping plate with high efficiency

Sensitivity: the fluid in the hydraulic system is basically in-compressible, and there is no hysteresis effect, once pneumatically operated, the stamping plate can complete travelling quickly with high sensitivity

Reliability: hydraulic components has a simple and durable structure and can withstand high pressure and high speed operation, they also have self-lubricating and self-cooling properties, allowing them to work stale for longevity

Adaptation: Adapt to various working environments and working conditions, such as high temperature, low temperature, high altitude, humidity, corrosion and etc

Safety: various safety protection devices and control systems can be used to ensure the safety of stamping plate

This Hydraulic Hot Foil Stamping Machine for Plastic Crates is guaranteed to achieve stable and continuous high pressure and is suitable for hot stamping, concave and convex embossing of large size products, particularly for big hollow plastic container, that request suspended stop in working position with utmost pressure applied

04: Salient Characters

Characters of Hydraulic Hot Foil Stamping Machine for Plastic Crates

Bench made of high strength cast steel forging, has a very high flatness and stability

Thread rinsing institutions to adjust the table lift to facilitate the opening and closing of space according to the height adjustment of the product

Relay control program is running, easy operation and easy maintenance

Pairs of button control the stamping head up and down, security is greatly enhanced

Hydraulic actuator instead of the pneumatic one, stamping pressure significantly improve the stability is greatly enhanced

Stainless steel heating rod to execute quick heating-up, that is convenient to replace and monitor

Heating plate can be removed to facilitate installation and replacement gilt template

Ironing board and table parallelism can be adjusted to facilitate the flexible adjustment depending on the size of different regions of the pressure

Automatic temperature control system can be set depending on the product temperature

Hot foil stamping degree of time and rolls of time can be set freely according to different technical requirements

Foil paper automatic feeder, conveyor length can be set according to the size of stamping area

MFR: KEEPLEADER™ has modified and designed Hydraulic Hot Foil Stamping Machine for Plastic Crates to accommodate our customers’ unique and special requirements, pls contact KEEPLEADER™ for tech assessment

Detailed Images

Hydraulic Hot Foil Stamping Machine for Plastic Crates takes bespoke construction in #1: replacement parts: our components adopt international stander to support local purchasing for future replacement if any malfunction #2: custom fixtures: one of the key ingredients to success is appropriate fixture or tooling to fit versatile crates or align them before printing, hot foil stamping machine supply can design and facilitate fixture from simple to complex depending on the application and speed of printing #3: Tailored throat/nose of supportive holder in depth and vertical height: the user often apply gold blocking on the surface of different crates of sizes and shape, the adjustable throat made of extensive plate is constructed #4: built-in casters: the user can move this Hydraulic Hot Foil Stamping Machine for Plastic Crates freely in different workable location of working shop

Contact UsHydraulic Hot Foil Stamping Machine for Plastic Crates has compact structure, but robust construction, adjustable pressure and loading depth vary on versatile gold blocking on the surface of plastic crates, keepleader, we are reliable manufacturer and commit to provide affordable and customized hot foil stamping machine, thanks for our tech team, they are quality-orientation with your verification, only ship out the finished machine after your validation

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader