Circuit Board Packing PCB Skin Vacuum Packaging Machine of Hardware_Fitting_Carpentry Tool Cardboard Film Pack Sealing Equipment

Circuit Board Packing PCB Skin Vacuum Packaging Machine

Circuit Board Packing PCB Skin Vacuum Packaging Machine is available in customized construction of heating mode, maximum loading size and type of feeding tray, with skin vacuum packaging machine, products are skin packaged to a substrate card with a sheet of transparent film, which is softened with heat and vacuum sealed over the product and card, skin packaging provides lock down product protection, product visibility and tamper evidence, a lower cost packaging option, skin packaging is often used to display products and protect products during shipping and processing, following the skin packaging process, roller die cutting machine is added as a finished option, often times, multiple products are skinned to one card and then roller die cut into individual packages, skin vacuum packaging is often used to display sharp objects like saw blade or drill bits and tamper evidence application, in addition, perform a protective packaging for circuit board transportation

Product description

Application | ||

Circuit Board Packing PCB Skin Vacuum Packaging Machine Application 1: wide application range 2: save cost 3: packed in any shape without mould 4: packing procedure is simple 5: transparent, stereo sense is strong, moistureproof, dustproof Main parameter | ||

Parameter | ||

model | KLP-390 | KLP-540 |

Voltage of power | 220V / 380V 50Hz | |

power | 7.5KW | <10KW |

Packing area | 390×540(mm) | 540×780(mm) |

productivity | 50-60(pcs/h) | 50-60 (pcs/h) |

material | Skin packing film | |

Film width | 450(mm) | 600(mm) |

Overall dimension | 610×880×1350(mm) | 1250×850×1350(mm) |

pack measure | 980-720*1420(mm) | —*—*1420(mm) |

weight | 180kg | 260kg |

MFR: KEEPLEADER™ have modified and designed Circuit Board Packing PCB Skin Vacuum Packaging Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Product uses

Circuit Board Packing PCB Skin Vacuum Packaging Machine is similar with blister packaging, both are transparent packaging,however, skin vacuum packaging machine gains contouring fit the products tightly after sealing that perform protective packaging, particularly for industrial parts, small tools, hardware for assembles,automotive aftermarket parts, gardening tools, construction parts, and many other products in resulting from dust-proof, moisture-proof, tamper-proof and loosing resistance,not only for these advantages but also for advertising performance

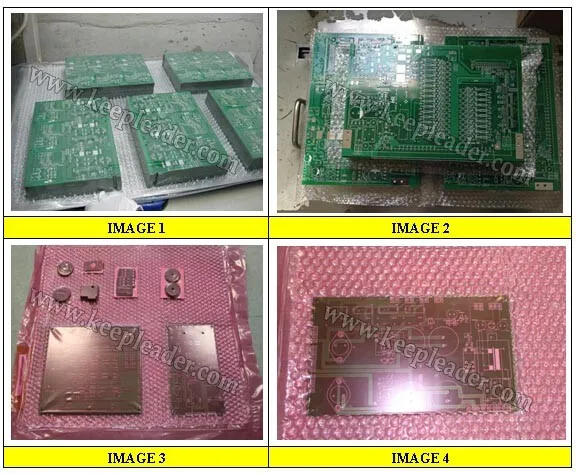

Detailed Images

Circuit Board Packing PCB Skin Vacuum Packaging Machine is reliable transparent packaging solution for small tooling, hardware and other tiny metal assembles, it have simple working procedures, the master sheet of skin board is placed in a skin packaging machine, heated skin film drapes over the master sheet, a vacuum drawn, tightly contouring a round the product, and heat sealing to the backer card, the skinned mater card is removed from the skin packaging machine. And achieve the final cutting steps in roller die cutting machine

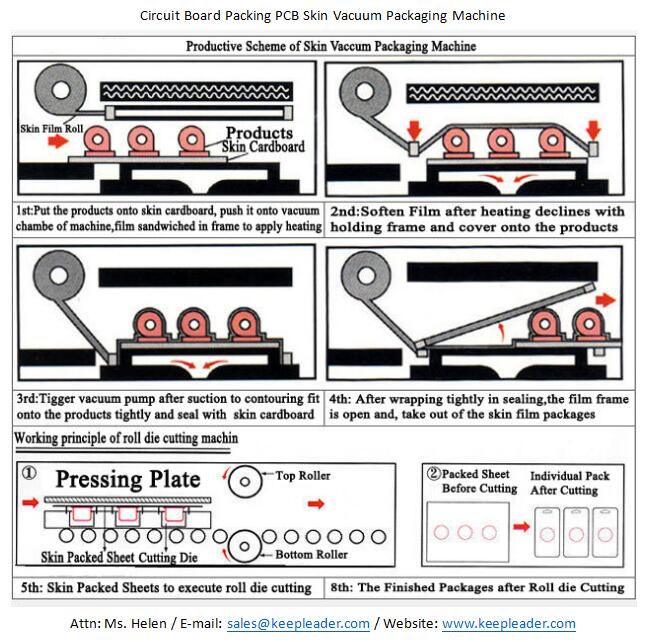

Production Flow

Circuit Board Packing PCB Skin Vacuum Packaging Machine has simplicity in packaging process, in order to create a high quality skin package requires specialized skin paperboard backer card with specific inks and heat-seal coating, skin film, and equipment to seal and die-cut material sheet, herein, we’d like introduce the brief procedures for operation guidance, 1st: manually place the parts on the master sheet of skin board;2nd: the master sheet of skin board is placed into the chamber of skin packaging machine;3rd: in skin packaging machine, heated skin film drapes over the master sheet;4th: a vacuum is drawn, tightly contouring around the parts, and heat-sealing to the backer card;5th: the skinned master card is removed from the skin packaging machine;6th: the master sheet is moved through a roller die cutter to cut into pieces containing individual products, key-slot, rounder corners, and internal die cuts perhaps be achieved simultaneously

Contact Us

Circuit Board Packing PCB Skin Vacuum Packaging Machine earns reputation because of prominent performance in PCB/circuit board packaging,that is benefited from keepleader’s advantages, such as: 1st: knowledge and experience: we are professional manufacturer of skin packaging machine over decades, our dedicated team will take the time to understand your needs and work with you to provide skin packaging solution to fit your budget and your application;2nd: affordability and efficiency: the use of semi-automated or fully automatic skin vacuum packaging machine will completely transform you packaging process making it faster,more efficient and more affordable.3rd: variety: keepleader, we offers a wide range of packaging equipment including skin vacuum packaging machine, blister packages ultrasonic welding machine, and high frequency blister welding machine, which all can integrated in automatic production line,supposing that yuo cannot find your concerned model, kindly consult it with our sales representatives, believe that we are capable of working out a reliable and affordable solution for your individual production

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader