Plastic Bonding Welder Hot Plate Welding Machine of PP_PE_PA Tail Light_Water Tank_Ball Pneumatic Heat Melting_Staking Equipment

Plastic Bonding Butt Welder Hot Plate Welding Machine

Plastic Bonding Welder Hot Plate Welding Machine is traditional thermoplastic butt jointing technique, that is melted and solidified process with combined electric heated and precision control of axial loading for plastic bonding, particularly for semi-crystalline, likely PE,PE,HDPE,PA and POM that is difficult for ultrasonic welder, but hot plate welding prove its advantages, additional salients are gratified prominent performance in characters of simple and reliable; suitable complex part geometries,even in the joining plane; can be adapted for use with materials which have different melting temperature and melt viscosity; relatively high tolerance to imperfections on the mating surfaces

Product description

Mainly parameter | |||

Description | Precision Vertical hot-plate welding machine | ||

model | KL-3040 | KL-4050 | KL-5060 |

power | 10KW | 15KW | 20KW |

voltage | 380V/440V | 380V/440V | 380V/440V |

weight | 850KGS | 850KGS | 850KGS |

Size | 1500*1025*1900 | 1500*1025*1900 | 1500*1025*1900 |

Working area Productive | 300*400 2-5pcs/min | 400*500 2-5pcs/min | 500*600 2-5pcs/min |

Pressure | Air pressure | Air pressure | Air pressure |

Application | |||

Plastic Bonding Butt Welder Hot Plate Welding Machine Is Beneficial To Manufacturers Seeking To Join Thermoplastic Parts Where Both High-Strength And Hermetic Seals Are Required, Or Where Parts Have Complex Geometries, Such As Irregular Shape, Or Curved Or Internal Walls, pls contact KEEPLEADER for more its introduction in joint design Lights of car, water thanks, electric irons, washing machines of balance ring, auto toilet, hand shower,LCD/TV frame,dash board,battery, filter, coolant/oil tank, instrument cluster panel, door trim, bumper, engine cover, speak frame and other irregular and larger plastic parts | |||

Features and functions | |||

High stretch, hermetic welding effect Can make circular joint, which is not ok for ultrasonic welding Dissimilar material is ok No consumables, fumes, emissions and noise Easy operation, high efficiency, wide cope of application Multi station/multi stage welders Achieving watertight and airtight welding Excellent for welding large or irregular work pieces PLC control, easy and convenient operation All the process date can controlled at the computer system, without mistake Digital PID temperature control function, resulting in more stable welding temperature Four columns support the design guide to ensure together, the level of accurate and well-behaved straight strong mechanical structure. Brand big cylinder pressure to ensure sufficient stability when welding Welding large surface, by the effect of melting faster than the efficiency of solid good looking | |||

MFR: KEEPLEADER has modified and designed Plastic Bonding Butt Welder Hot Plate Welding Machine to accommodate our customers’ unique and special requirements, pls contact KEEPLEADER for tech assessment with your detailed application

Detailed Images

Plastic Bonding Welder Hot Plate Welding Machine pioneers in producing strong and sealed thermoplastic assemblies, that are complex in shape, particularly for semi-crystalline, likely PP,PE, dissimilar materials having similar welding points and melt viscosity, its outstanding performance in permanent butt bonding attains applause of end user, such as, strong, and hermetic welds,ideal for assembling large components likely fuel tanks, fluid reservoir and more; easily automated, our hot plate welding machine can be easily automated and integrated into a workflow that produces strong, hermetic welds; cost-effective, if joint like aesthetics are not priority, our hot plate welding machine offers a cost-effective solution for welding large and complex parts

Product uses

Plastic Bonding Welder Hot Plate Welding Machine is used for butt bonding in plastic assembling, several names exist for this process, heated mirror welding, mirror welding, hot plate welding and hot blade welding, this welding process is especially suitable for welding large plastic parts, parts with complex geometry, it is used to produce both technique and aesthetic assemblies,the plastic parts are in contact with the hot plate thus allowing the transmission of heat energy to the parts to be assembled, when the material fusion is reached, the hot plate is withdraw,the plastic parts are then assembled together, this technology ensures no-removable assemblies,that can withstand high mechanical stresses and ensure sealing

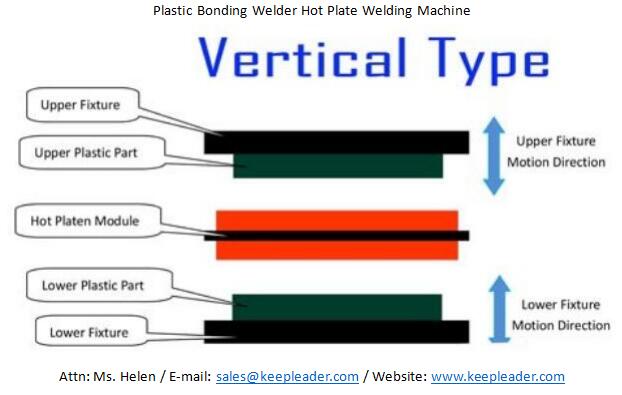

Tech Illustration

Plastic Bonding Welder Hot Plate Welding Machine is the process of welding two plastic parts together using a heated tooling plate, a welding rib or bead on each component is brought into contact with the hot plate, heat conducts into the welding rib causing it to melt, the heated tool is then removed and parts are pushed together until they bond to one another

Contact Us

A professional-designed joint at the assemble interface is critical to achieve a robust hot plate butt bonding, likely over-flow trapped design to gratify aesthetic priority, our technique team can provide you with guideline to optimize your parts design for our Plastic Bonding Welder Hot Plate Welding Machine and achieve the strongest weld possible, we are always ready for our consultation, anticipate your initiation to proceed with our one-stop service

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader