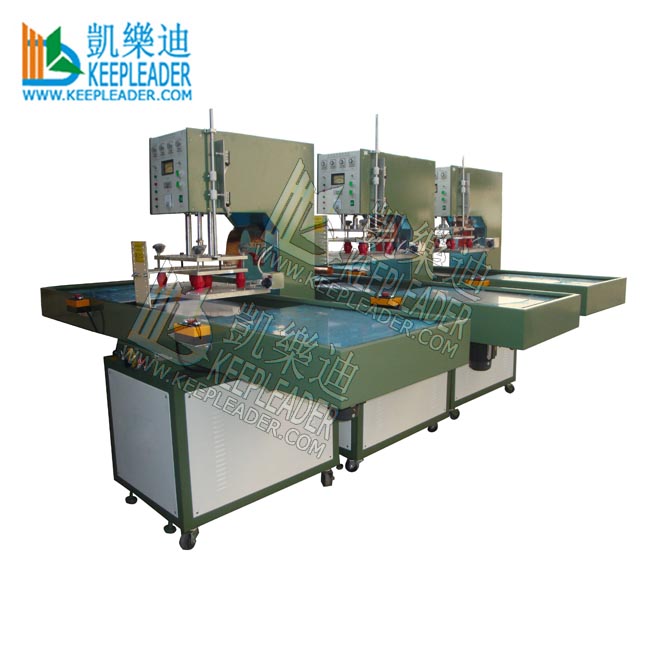

Clam Shell Blister Paper Card Sealing High Frequency Welding Machine of Shuttle Tray PVC_PET Bubble Shells Packing HF/RF Welders

Clam Shell Blister Paper Card Sealing High Frequency Welding Machine

Clam Shell Blister Paper Card Sealing High Frequency Welding Machine has ♦1:Power:5kw~25kw ♦2: Auto Shuttle Tray ♦3: Customized Toolings ♦4 Pressure Made as requested

Product description

Mainly application | ||||

Clam Shell Blister Paper Card Sealing High Frequency Welding Machine for double-sides, welding of inflatable toy, raincoat, and any PVC, or PVC contained 30% up | ||||

Character | ||||

Using high Q oscillation value is installed in this machine which is stable and reliable in output. High sensitive spark depressing circuit is used for preventing mould damage. The rotating-plate, pusher-tray structure can improve the production effectively. The cylinder propping positioning gadget can make precise positioning of turntable. It is made of a whole set high quality imported components | ||||

Technique specifications | ||||

Model | KLR-5000S/A/ET | KLR-8000S/A/ET | KLR-10KWT | KLR-15KWT |

Power | 5000W | 8000W | 10KW | 15KW |

Voltage | 220V/380V 50/60HZ | |||

Frequency | 27.12MHZ | 13.56MHZ | ||

Input power | 8KVA | 15KVA | 18KVA | 25KVA |

Rectifier | SILICON DIODE | |||

Oscillation tube | 7T85RB | 7T69RB | E3069 | 8T85RB |

Max pressure | 350kg | 500kg | 800kg | 1000kg |

Electrodes Gap | 160 up to 200MM | |||

active horn | 175MM | 200MM | 150MM | |

upper electrode | 200*350 | 400*600 | 500*700 | 600*900 |

lower electrode | 400*600 | 600*800 | 600*800 | 600*900 |

Range of temperature | 30 up to 200 Adjustable | |||

Welding time | 0 up to 10S Adjustable | |||

Productivity | Equal or less 4000times per 8h | |||

Net weight | 280kg | 330kg | 360kg | 500kg |

Overall dimension | 1000*660*730 | 1000*720*1860 | 1000*720*1860 | 2500*2100*2000 |

Standard equipment:

Name | Origin | Brand |

Air driven components | Taiwan | Airtac |

AC contactor | Korean | LG |

Relay | Japan | Omron |

Electron Tube | Japan | Toshiba |

Time controller | Taiwan | CKC |

MFR: KEEPLEADER™ have modified and designed Clam Shell Blister Paper Card Sealing High Frequency Welding Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Product uses

The most important factors influence Clam Shell Blister Paper Card Sealing High Frequency Welding Machine: #1: electrical power #2: pressure applied #3: welding time #4: cooling time, Finding the optimal process parameters will depends on your specific equipment, the materials involve and the specific geometries including thickness and area to be welded, achieving optimal results is often an experimental process guided by experience, as a guiding rule, the thicker material and focus on short welding times you need, the stronger electrical power you need

Machine Uses

Clam Shell Blister Paper Card Sealing High Frequency Welding Machine takes prominent features in #1: High Automation degree: auto turntable indexing or shuttle tray with high frequency alternation; automatic robotic unloading device, auto loading paper card is available to combine a whole automatic production in blister packaging #2:Flexible operation: quick shift in auto and manual mode, close the automatic turntable or shuttle tray, the working model also set manual stationary status as a free-standing model, touch screen is convenient accessed in setting, operation, reading with programmable logic control system #3: customized solution: support quick-changeover upper electrodes and bottom nests among different blisters/clamshell in shape and size, automatic feeding paper card and loading parts are acceptable in construction as per demands

Contact Us

KEEPLEADER is reliable supplier in blister sealing, Clam Shell Blister Paper Card Sealing High Frequency Welding Machine is our semi-automatic solution in welding of PVC/PET Blister packaging, which also can combine your or specified automatic feeding, loading device for large scale production, if the configuration and parameter herein are not your concerned, please consult with your sales with your expectation, we promise to complete them after technical confirmation, and let your double examine prior to production

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader