Ultrasonic Label Cutting Machine for Fabric Tape_Satin Ribbon_Nylon_Textile Belt Cutting Machine of Automatic Tap Label Cutting

Ultrasonic Label Cutting Machine

Ultrasonic Label Cutting Machine is #1: automatic feeding #2: ultrasonic agitation cutting #3: in different size and shape for #4: label, table, belt, tube, ribbon band.

Product description

Parameter | |

Ultrasonic power | 1500-2000w |

Ultrasonic frequency | 20khz |

Voltage | 110V-240V, 50HZ/60HZ |

Productivity | 200-230 pcs/minute |

Air pressure | 4-6kgs/cm2 |

Cutting width | 80mm |

Cutting thickness | 1-4.5mm |

Precision | ±1mm |

Dimension | 1200*700*1300mm |

Weight | 120kgs |

Application | |

Ultrasonic Label Cutting Machine is intended for cutting shapes in difference size, the cutting material includes plastic belt, synthetic belt, non-woven belt, and fabric, nylon belt, for example: ribbon, plastic bandage, safety belt, mask ear-loop bandage, plastic rope, braid, cloth, and non woven fabric, nylon, coated fabric, needlework cloth brand, handle and etc | |

Character | |

NTK Ultrasonic transducer, strong power and stable performance 20khz ultrasonic machine, can supply strong output, but little noise Build-in PLC, convenient and visible for operation and debugging Cutting length and width is adjustable Cutting speed can be chosen Cutting shape can completed by changing mold Automatic cutting, and winding, auto detect and rectify the deviation No spark and fog during cutting, won’t damage the fabric edge No preheating, cold cutting, but have not stringing Cutting and sealing edge can complete in one process | |

KEEPLEADER™ remain its right in modify the data for updated design of Ultrasonic Label Cutting Machine

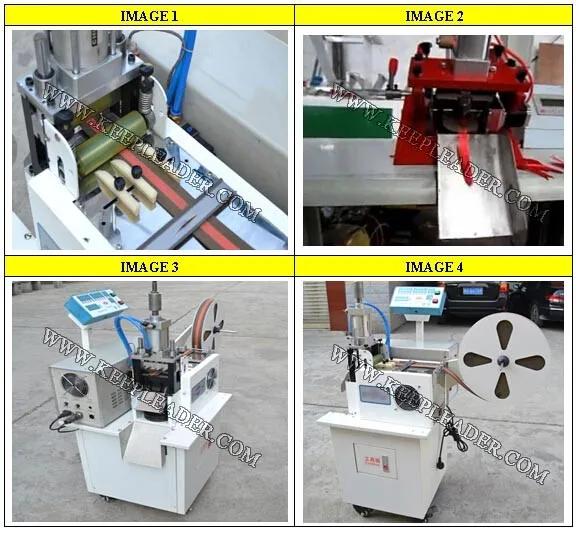

Detailed images

Ultrasonic Label Cutting Machine is computerized in control system, ultrasonic molecular agitation tearing in cutting, servo driven in auto feeding, compact structure in cost-saving and reliable and consistent in cutting performance

Prodcut uses

Ultrasonic Label Cutting Machine is available for belt, strip, label, tube, tape, ribbon made of fabric, satin, webbing, woven, textile, nylon, elastic in cutting within limited width

After-sales service

After purchasing at KEEPLEADER™ is first step of our after-service, all of machines at KEEPLEADER™ has one year guarantee, we provide free samples for

defected parts to do replacement except for human damage, under information for your notice

01: KEEPLEADER™ always posts the new technical file in our homepage that can help our client

in new technical information of machines’ design, character, application, operation, maintenance,

and related, KEEPLEADER™ also welcome our clients feed back the machines’ working condition

that can get one to one service

02: If the machine you purchased has any defects, please contact sales representative

at KEEPLEADER™, we will assign our experienced engineer analyze your case and provide technical

support, in case of damaged parts that cannot repair, KEEPLEADER™ will provide a new parts to replace the defect

03: For any replacement and maintenance, KEEPLEADER™ has user manual and training video

04: KEEPLEADER™ can go to oversea for on-site training

05: KEEPLEADER™ can provide remote training

06: KEEPLEADER™ can provide electric diagram under request

Contact Us

Our company aim to provide world renown brand of Ultrasonic Label Cutting Machine, it is our eternal pursuit for exchange our sincerity, hard work and sweat for customer satisfaction, welcome your inquires, we, keepleader firmly grasps the opportunity of rapid economic development, adhere to the business philosophy of “forging ahead, surpassing” respecting talents, focusing on products and pursuing higher goals based on unremitting efforts

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader