Saw Blade Ultrasonic Cleaner For Fan_Mill Saw Blade Ultrasonic Cleaning_Washing For wood working Machinery Saw Blade Cleaning

Saw Blade Ultrasonic Cleaner

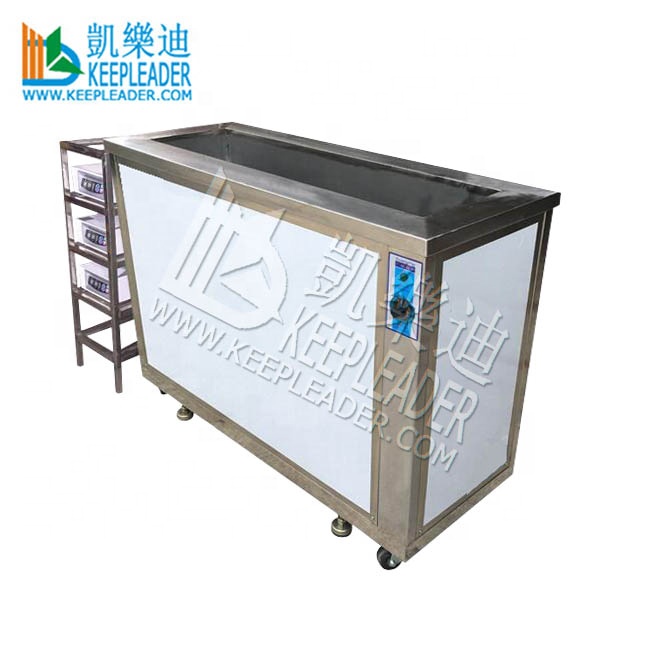

This "Saw Blade Ultrasonic Cleaner" has inner size: 1000*500mm*1000mm, if you need custom size, pls advise us

your preferred, also advance notice us if you need circulation and filtering device, hot air drying and lifting system

Product Description

01: Parameter

Name | |

Model | KLE-1080 |

Ultrasonic Power | 4000w |

Ultrasonic frequency | 28khz |

Inside size of cleaning tank | 1000*500*1000mm |

Blade Size | 58~89cm |

Power Supply | 220V,60HZ or 380V/50HZ |

Packing Volume | 2.4CBM |

Net Weight | 220kgs |

Gross Weight | 260kgs |

02: Application

Saw blade ultrasonic cleaner makes saw blade repair faster, safer and more reliable, furniture manufacturers, closet fabricators and any industry cuts wood for their final product requires consistent saw blade maintenance, ultrasonic cleaner removes wood pitch residue faster and safer that overnight cleaning methods, this saw blade ultrasonic cleaner can clean multiple blades up to 89cm in diameter, often in as little as three minutes, then, blades can be dipped in a rust inhibitor, flash-dried and prepared for assessment and sharpening

03: Highlighting

Leans even the toughest substances form the dirtiest blades

Stream lined process increases efficiency and productivity

No soaking or hand cleaning

Uses safe water-based solutions

No Training required

04: Advantages of ultrasonic cleaner for saw blade

Over time, pitch and resins build up on the cutting edges of saw blades, this effectively costs the edges, making the blade act as though it is dull, friction and heat increase, cutting is more difficult, and the resulting cut edges are not as clean as they cold ne, while it may seem counterintuitive, dull blades are more dangerous that sharp blades, blades cut at maximum efficiency reduce the strain on the saw’s motor

If you find that your blades and bits just aren’t performing like they used to, you might not need to send them out for a sharpening. They might just be in desperate need of a good cleaning. Over time, pitch and resin builds up on cutting surfaces and causes them to cut less effectively. If the buildup isn’t removed, the increased friction and heat will accelerate the dulling of the edge and eventually the blade or bit will be toast.

Detailed Images

Saw Blade Ultrasonic Cleaner can construct specified dimension and function to gratify your cleaning demands and purchasing budget

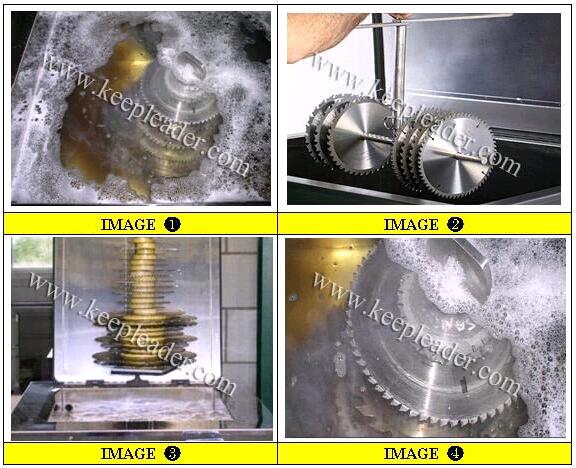

Product Effect

For "Saw Blade Ultrasonic Cleaner" the saw blade accumulate in the cleaning basket, so its necessary to double check the maximum cleaming weight with our sales representatives

Buying Gides

BUYING GUIDANCE

01: Choose your correct system

For customers demanding multiple stage ultrasonic cleaning and high efficiency parts drying, KEEPLEADER™ multi-stage consoles provide the same efficient, effective ultrasonic cleaning technology plus the ability to move the items items through additional wash and rise stages, KEEPLEADER™ will design a custom-sized and custom-featured ultrasonic cleaning machine to meet your specific needs

011: heated ultrasonic cleaning

012: heated ultrasonic cleaning + heated rinse

013: heated ultrasonic cleaning + heated ultrasonic rinsing

014: heated ultrasonic cleaning + heated ultrasonic rinsing + hot air drying

015: Inner size of cleaning tank, frame construction, custom color, ultrasonic frequency

02: Choose your tank size

021: the length*Width*depth you wanting

022: advise KEEPLEADER™ the size of your cleaning parts and cleaning efficiency

03: Each system includes:

031: Full insulated stainless steel tanks

032: Exterior power coat finish

033: Digital temperature controls-each tank

034: Digital timer-controlled ultrasonic cleaning

035: Dual stage filtration-cleaning stage

036: Single-stage filtration rinse stage

037: Low-level float sensors-each stage

04: Exceed industry standards

041: All size available, including bench version

042: High quality stainless steel construction

043: For vapor degreasing, cleaning and drying applications

044: Full solution control features

For Saw Blade Ultrasonic Cleaner, you need to calculate inside size of cleaning tank with your workable loading size in cleaningContact Us

We welcom the opportunity to explain every last details and all of the options available in fact, and. Won't waste your time and ours, our goal is to educate our potential customers and let them make an informed dicision, pls contact KEEPLEADER for more info of Saw Blade Ultrasonic Cleaner

☺ Attn: Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone/Wechat/Whatsapp: +86 13590415784

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader