Spin Butt Fusion Welding Machine For Tube_Filter Cartridge Spin Welding equipment of Spin Friction Plastic Welding Machine

Spin Butt Fusion Welding Machine For Tube_Filter Cartridge Spin Welding

Spin Butt Fusion Welding Machine For Tube_Filter Cartridge Spin Welding consists of generating heat by rotational friction at circular joint to weld thermoplastic parts, the spin friction welder applies force axially while rotating one part against its stationary mate, the resulting friction generates heat that melts the parts at the spherical interface,once rotation stops, the material cols and solidifies, forming a welded assemble with impervious effect,for cases where the parts must be oriented in a particular manner with respect to each other, the spin friction welder stops the rotation at the precise angular orientation that driven by servo motor as another solution

Machine Description

01: Parameter

Spin Butt Fusion Welding Machine For Tube_Filter Cartridge Spin Welding | |

Model | KL-2P |

Motor Power | 1500W |

Power Supply | AC 220/380 V 3P |

Welding Diameter | 30-150MM |

Journey | 80mm |

Air Pressure | 0.2-7Bar |

Production speed | 1Pcs/0.1-3.0S |

Delay Time | 0-100 seconds / adjustable |

Hold Time | 0-100 seconds / adjustable |

Torsion | 10 N*M |

Gross Weight | 380kgs |

Dimension | 1.1*1*2.1=2.31CBM |

02: Application

KEEPLEADER’s high torque Spin Butt FusionWelding Machine is designed to accommodate a wide range of spherical andcylindrical applications, Spin Butt Fusion Welding is the preferred techniquefor thermoplastics with a circular axis joint which have high bondstrength/hermetic requirements, during Spin Butt Fusion Welding, one part isheld stationary in a holding fixture while a second parts is rotated against itunder pressure at speeds up to 1600rmp, this resulting friction causes thejointing surfaces to melt and fuse together, producing robust, water andair-tight welds

03: Character

Ability to weld parts with circular jointthat are not easily welded by ultrasonic

Relatively fast cycle times when comparedwith other methods

Compatible with most thermoplastic

Ideal for welding of PP and PE materials

Ability to weld several dissimilarmaterials

No consumables, fumes, or emissions

High strength, hermetic welds are typical

Heat confined to weld interface

Easily automated

Low cost, quick change tooling

Low maintenance

Low power consumption

04: Spin Butt Fusion Welding Tool

Driver: Customized tool used for spinningone half of welding article and generate the melting, drivers commonly useraised or relieved

Holding fixture: Thenon-rotating part half must be grip securely so that one part half does notrotate and remains in alignment with the spinning part half

Spin Butt Fusion Welding Machine For Tube_Filter Cartridge Spin Welding varies from fixtures of both manual and pneumatic clamping

Machine Uses

Spin Butt Fusion Welding Machine For Tube_Filter Cartridge Spin Welding is suitable for sepherical or cylindrical thermoplastic parts bonding, specially, for PP,PE, Nylon parts, which is not easy for ultrasonic welding

Detailed Images

Spin Butt Fusion Welding Machine For Tube_Filter Cartridge Spin Welding is suitable for sepherical or cylindrical thermoplastic parts bonding, specially, for PP,PE, Nylon parts, which is not easy for ultrasonic welding

Buying Guides

Designing for Spin Butt Fusion Weldingprocess produces a welded joint which in many cases, yields a weld strengththat is consistently equal to or stronger that any other area of the part, as aresult, the weld area can most often the exposed to the same strains andstresses as any other area of the parts

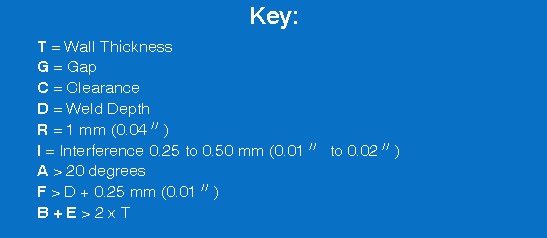

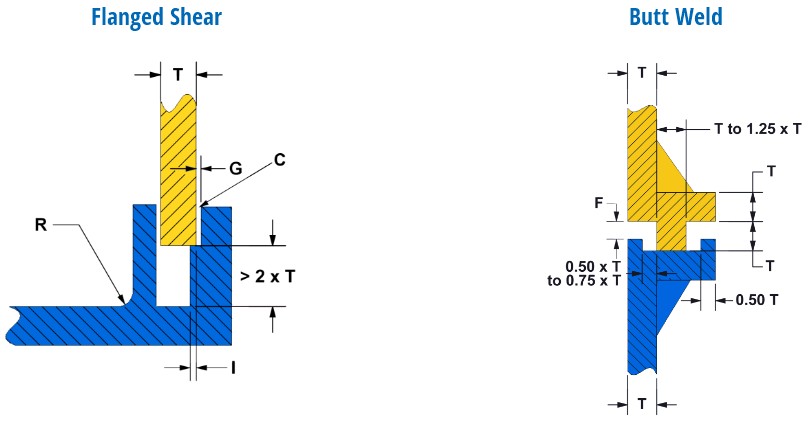

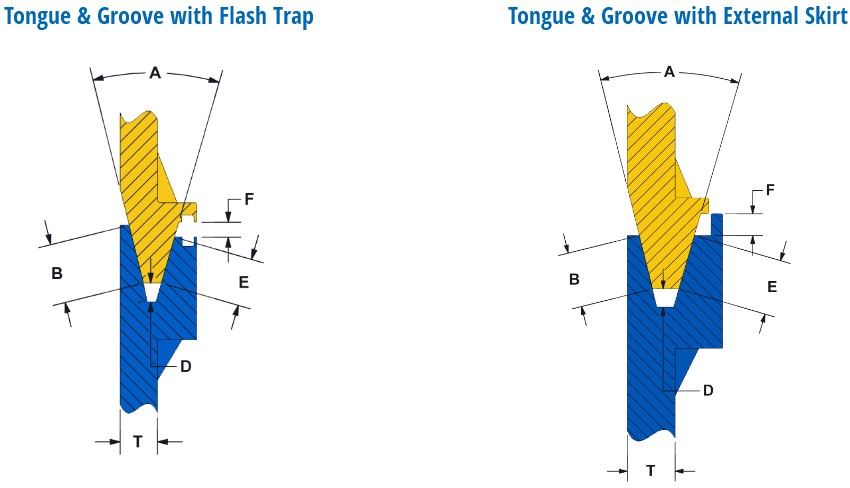

01: Weld joint designs:

A good Spin ButtFusion Welding joint should have a weld area equal to or greater that a typicalwall section of the part, joints should also provide sufficient part-to-partalignments

Notes: joints should the designed withlocating features for part-to-part alignment, to prevent deflection, partsshould be designed such that wall thickness is robust enough to resist weldforce (50~400 ponds), adding a return flange adjacent to the weld joint canensure proper support

02: Drive feature designs

Drive features are profiles in the partdesign which provide suitable surfaces to transmit the drive torque during thespin welding process, they also provide loading for loading and orienting thepart, some parts may have inherent drive features, which other designs manyrequire them to be designed into the [art, drive features many be: notches,ribs, through-holes and other non-circular features

Contact Us

We welcome the opportunity to explain every last details and all of the options available in fact, and. won’t waste your time and ours, our goal is to educate our potential customers and let them make an informed decision, please contact KEEPLEADER for more info of Spin Butt Fusion Welding Machine For Tube_Filter Cartridge Spin Welding

☺ Attn: Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone/Whatsapp: +86 13590415784

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader