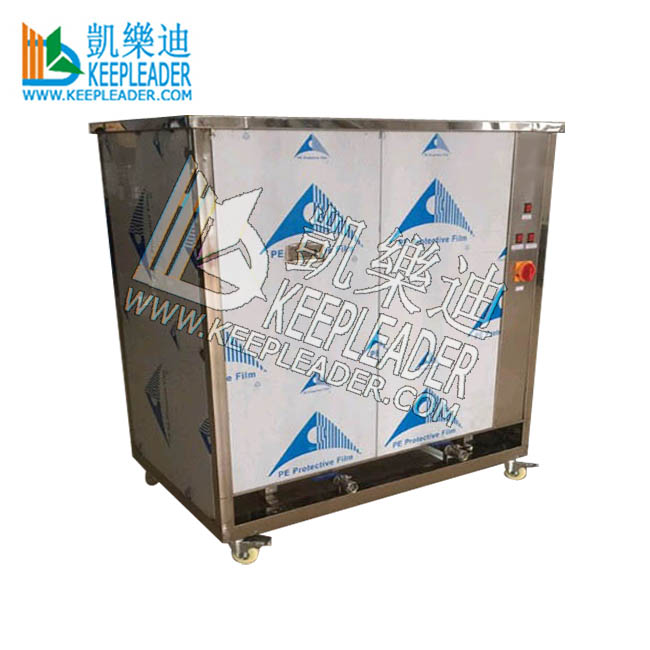

Dual Tanks Ultrasonic Vapor Degreaser of Ultrasonic Vapor Cleaning Machine for Aerospace Components Industrial Vapor Degreasing

Dual Tanks Ultrasonic Vapor Degreaser

KEEPLEADER’S engineers and service specialists offer excellent engineering support around the world, our tech team offer application, evaluation, testing, technical service, contract maintenance, replacement parts, training and installation, we also can customize our Dual Tanks Ultrasonic Vapor Degreaser to your need, if you are thinking about custom design and sizing,please let us know what are you looking for?

Machine Description

Dual Tanks Ultrasonic Vapor Degreaser

01:Application

Dual Tanks Ultrasonic Vapor Degreaser contain two sump, one is boiling sump, the other is ultrasonic agitation sump, there is condensing blanket on top, in boiling sump, the vapor zone is generated with low volume vaporized with precision heating, the ultrasonic sump is ceramically enhanced ultrasonic produces unrivalled cleaning with HFC,NPB and HCFC Solvent, the Dual Tanks Ultrasonic Vapor Degreaser is widely used in parts cleaning process of machinery, medical, aviation, electronic and other most industrial facilities

Precision cleaning medical device parts where critical that no chemical residue is left on parts

Manufacturing processes requiring precision cleaning of oils and particulates and quick drying

Semiconductor printer circuit board cleaning and flux removal

Aerospace parts cleaning for components required to conform to military specifications

Minimizing solvent loss in industrial cleaning process

Our Dual Tanks Ultrasonic Vapor Degreaser come in a variety of configurations depending on customer application, keepleader can size a vapor degreaser to fit not only your parts, but also you circle time and production requirements, with today’s solvent it is essential to size the vapor degreaser properly to ensure maximum solvent recapture through distillation cycle chilling coils

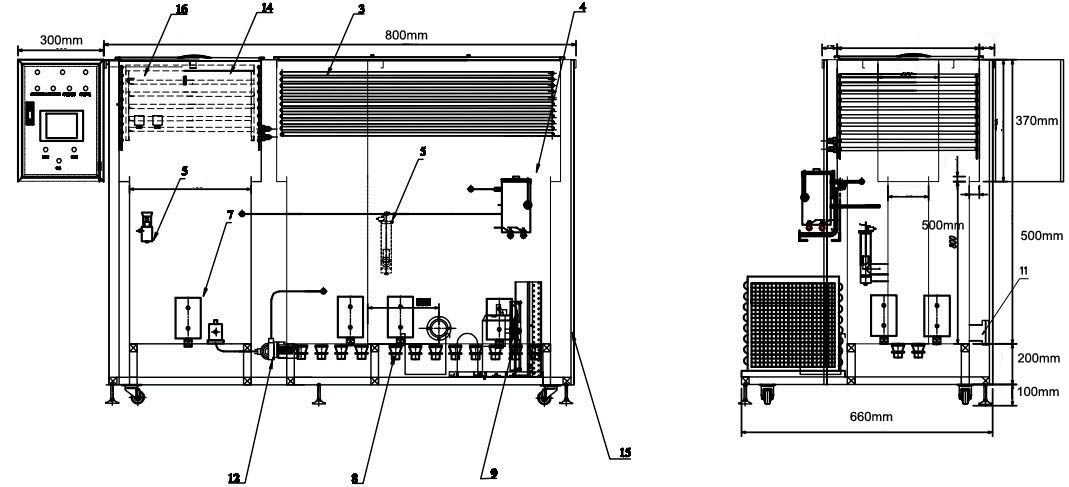

02:Parameter

Name | |

Model | KLE-2012R |

Power supply | 220v,60hz or 380v,50hz three phase |

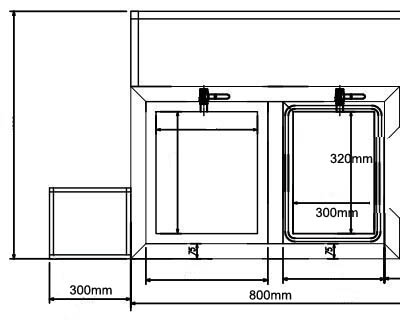

Ultrasonic sump size | 320*300*320mm |

Boiling sump | 320*300*200mm |

Vapor Zone | 320*300*300mm |

Footprint Size | 1100*660*1200mm |

Ultrasonic cleaning | 600watts of power at 40khz field replaceable components, adjustable power and sweep |

Vapor cleaning | Vapor cleaning zone above boil sump and ultrasonic sump |

Spray cleaning | Hand spray wand and large spray reserve tank |

Filtration of sonic sump | Continuous filtration |

Boil sump access door | “Easy ring” door system |

Sonic sump access door | “Easy ring” door system |

Primary condensing coil | Refrigerated stainless steel |

Low-Temp freeboard | Refrigerated stainless steel |

Freeboard Ration | 100~120% ratio |

Horizontal slide lid | Manual or automatic |

Solvent Safety and Temp Control | HTT, LTC, SVC,VU,RT and Low-Level Float |

Monitoring of the vapor degreaser’s correct operation condition | Comprehensive indicator light system and temperature displays |

03: Advantages

Water cooled primary condensing coils

PLC Control with automation capability

Low voltage controls for operator safety

Coolant indicator gives visual confirmation

Vapor Sub-Zero refrigerated cheeseboard coils

Electric low watt density immersion heaters

Electric low watt density immersion heaters

Heavy gauge stainless steel tank construction

Solvent cool down mode to minimize solvent loss

Heat over temp sensor to prevent heater damage

“Ready” light to notify operator the unit is set to run

100~120% cheeseboard ratio to limit solvent consumption

Re circulation with cartridge filtration and filtering pump

No water consumption or wast water treatment required

Compact footprint for easy integration in production flow

Stainless steel process tanks with bright annealed finish

Stainless steel condenser and chiller coils to avoid corrosion

Manual downtime cover/lid,Close loop condensing of vapor

Wash, rinse and dry with a spot-free finish in one compact unit

Easy open clean out door to quick access maintenance process

With gravity water separator with molecular sieve capability

Smaller footprint, faster cycle times compared to aqueous systems

Vapor, High temperature, solvent temperature, low level are adjustable

No exhaust required,Equipped with spray lance, Stainless steel finned coils

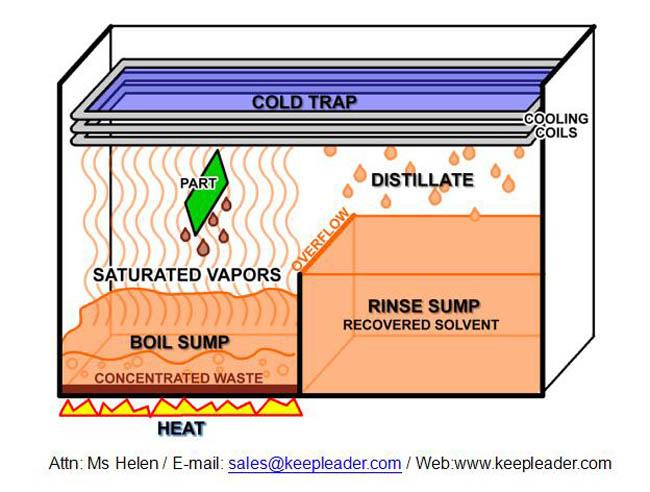

Graphic Illustration

Dual Tanks Ultrasonic Vapor Degreaser has basic function of #1: vapor sunp #2: Rinse Sunp, also optional of #3:ultrasonic sump, #4:distillation sump and #5: Spray wand

Overall Illustration

Dual Tanks Ultrasonic Vapor Degreaser is acceptable for various size, functional sump in complied with your required process

Contact Us

We welcome the opportunity to explain every last details and all of the options available in fact, and. won’t waste your time and ours, our goal is to educate our potential customers and let them make an informed decision, please contact KEEPLEADER for more info of Dual Tanks Ultrasonic Vapor Degreaser

☺Attn: Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone/Whatsapp: +86 13590415784

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader