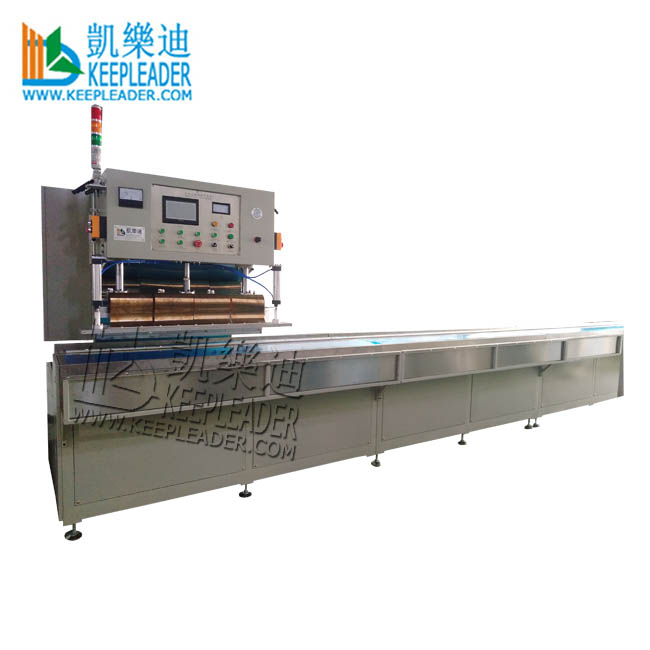

Auto Steps High Frequency Car Curtain Welding Machine For Car Cover Curtain High Frequency Welding of Canvas_Tarpaulin Curtains

Auto Steps High Frequency Car Curtain Welding Machine

The most important factors influence High Frequency Car Curtain Welding Machine : #1: electrical power #2: pressure applied #3: welding time #4: cooling time, Finding the optimal process parameters will depends on your specific equipment, the materials involve and the specific geometries including thickness and area to be welded, achieving optimal results is often an experimental process guided by experience, as a guiding rule, the thicker material and focus on short welding times you need, the stronger electrical power you need

Machine Description

Auto Steps High Frequency Car Curtain Welding Machine

01: Application

Auto Steps High Frequency Car Curtain Welding Machine is professional HF welder of large format structural membranes welding, like pool-lines, oil-booms, water cistern, tarpaulin, tents, tensile structures, advertising billboards, spark protection cloth, tent of truck, agricultural canvas, canopy, swimming pool covers, and other PVC/PU technical textiles, large PVC canvas, digesters, fabric, computer advertising, printing film cloth, the membrane structure, large format technical textiles, large cover for trucks and boats, membrane curtains for trucks, large swimming pool covers, temporary shelters, and other thermoplastic membrane structure made of shielding shaped products

02: Parameter

Name | Auto Steps High Frequency Car Curtain Welding Machine | |||

Model | KLR-8KWF | KLR-12KWF | KLR-15KWF | KLR-25KWF |

HF Power | 8kw | 12kw | 15kw | 25kw |

Input Power | 15KVA | 20KVA | 25KVA | 35KVA |

HF frequency | 27.12mhz | 13.56mhz | ||

Voltage | AC 380V,50hz-60hz or AC 220V,50~60HZ |

| ||

Spark suppress | NL-5557 high sensitive anti-spark system | |||

Welding Time | 0.01~9.99s adjustable | |||

Rectifier | Silicon Diode | |||

Oscillator | 7T69RB | E3130 | 8T85RB | 8T25RA |

Max pressure | 500kgs | 800kgs | 1000kg | 1500kg |

Electrodes gap | 150mm | |||

Active horn | 150mm | |||

Upper electrode | 50*50*800mm | 50*50*900mm | 50*50*900mm | 50*50*1000mm |

Packing Volume | 18.8CMB (with 8 meters length of movable bench) | |||

Gross Weight | 2600kgs (with 8 meters length of movable bench) | |||

03: Character

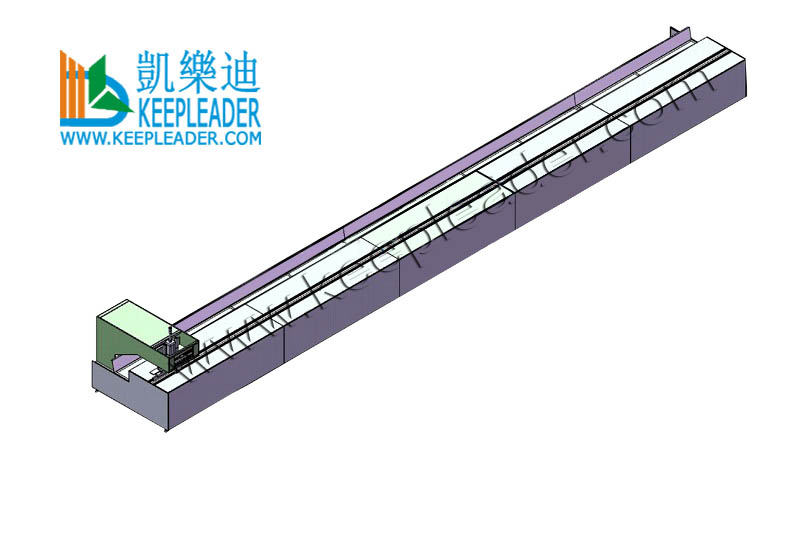

Customized length of movable bench, zipper guides is equipped

Linear bearing driven is servo motor controlled for precision and smart travelling

Touch screen programmable HMI / PLC and operation panel, two operation system

European-model square high frequency vibration box

Continuous HF welding for single line, double lines, even for curve lines

Movable welding head also can be used as freestanding

Customized working bench dimension, electrode holder dimensions and tooling

Laser guide projector generate two beaming lines to guide welding width

C-frame and G frame welded steel structure with integrated HF generator

Automatic high frequency turning technology

Vacuum bench and temperature thermostat are available

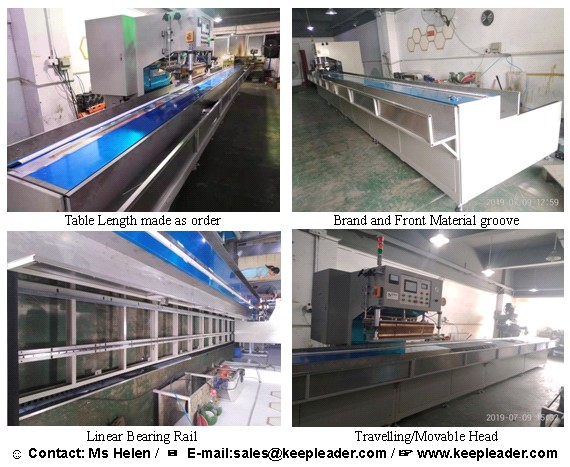

Detailed Images

Auto Steps High Frequency Car Curtain Welding Machine has an interchangeable electrode, or die, machined in the shape of the part to be welded, is used to apply power to the workpiece,so, the electrode, electrode holder, table length, material groove all made to your order

Product Uses

Auto Steps High Frequency Car Curtain Welding Machine Can weld thermoplastic membranes of PET, PETG, PVC, TPU, LDPE/EVA and Open Celled Polyurethanes

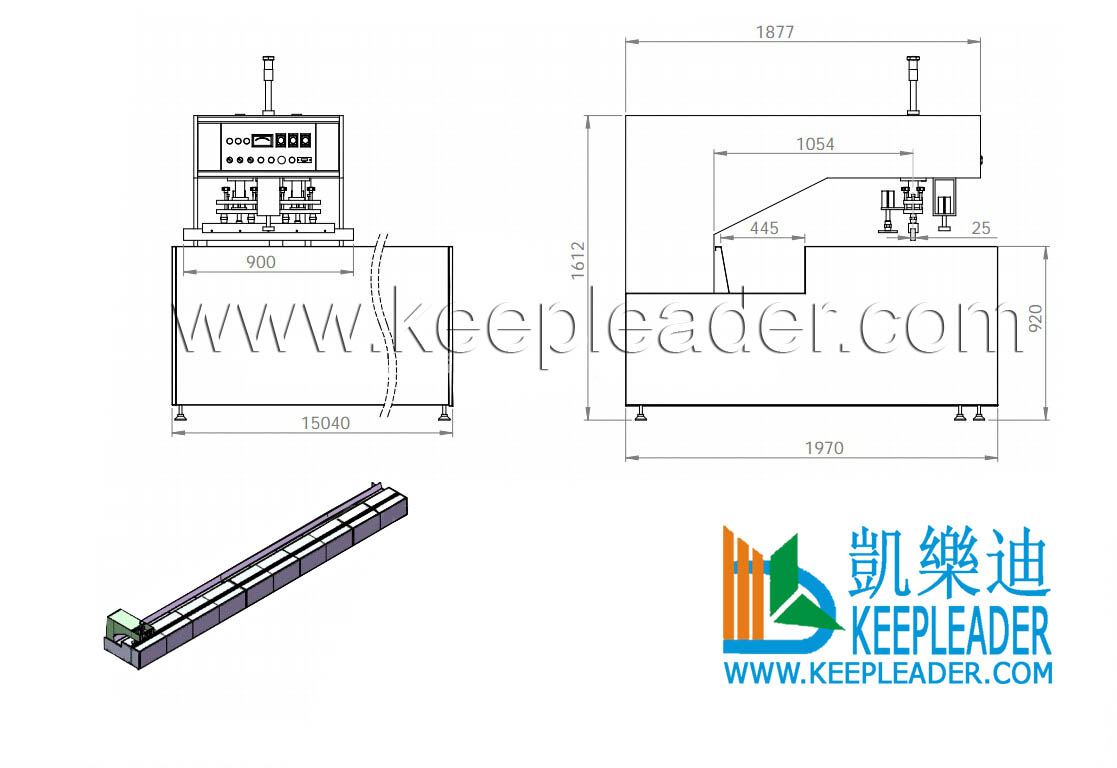

Drawing

Auto Steps High Frequency Car Curtain Welding Machine can have customized factors of #1: Electrode #2: Holder #3: Table #4: HF power #5: Auxiliary Functions

Contact Us

We welcome the opportunity to explain every last details and all of the options available in fact, and. won’t waste your time and ours, our goal is to educate our potential customers and let them make an informed decision, please contact KEEPLEADER for more info of Auto Steps High Frequency Car Curtain Welding Machine

☺ Attn: Ms Helen

✉ E-mail: sales@keepleader.com

☎ Tel: +86 755 84190358

☎ Cellphone/Whatsapp: +86 13590415784

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader