Cardboard Cake Box Bottom Forming Machine for Paper Cake Box Base Forming Equipment of Cake Paper Box Making Bottom_Base Forming

Cardboard cake box bottom forming machine

"Cardboard cake box bottom forming machine" is used to form/made paper birthday cake box in its base/bottom/tray, both round and square shaped bottom/base/tray are acceptable

Product Description

01: Parameter

Model | KLY-5040 |

Power | 0.05kw |

Power supply | 220v/380v*3P, 50hz/60hz |

Forming height | 8~40mm |

Paper gram | 3~120gram |

Driven mode | Pneumatic |

Air pressure | 0.6MPa |

Pressure | 15 tons |

Size of forming | Square shaped: 46cm, Round shaped: 52cm |

Forming speed | 200~350pcs/h |

Protection system | Grating protection+ start with two hands |

Operation mode | HMI touch screen |

Forming type | Square and round paper box bottom/base |

Overall dimension | 800*600*2300mm |

Material | Coated paper, gold paper, sliver cardboard, white cardboard Grease proof paper, PE coated paper |

Net weight | 900kgs |

Packaging volume | 2.5CMB |

02: Application

Cardboard cake box bottom forming machine can be sued for paper cardboard birthday cake box base forming, the shape can be round or square, maximum forming diameter is 52cm, and maximum forming height is 4cm, pneumatic driven

03: Highlighting

Wide application: applied for paper box bottom forming, the material can be coated paper, gold paper, silver cardboard, white cardboard, greaseproof paper, PE coated paper box

The bottom tools equipped with heating plate to form shape under top tools pressure

The machine can produce 6~20 inch round chase box bottom base or square cake box bottom base

The machine can improve efficiency and reduce labor

Digital operation panel, the setting is readable and visual

Forming pressure and stroke depth is adjustable

Forming, tighter and cutting in one circle

Tooling and mold support quick mounting and changing

Sturdy framework, the life-span can be over 15 years

Cold forming and cutting save the consumption and reduce the fire risk

Pressure and forming size are adjustable to produce various paper boxes

04: Production flow

Paper cardboard gluing →Pre heating →Drying →Paper cardboard base forming →Holding →Cutting Edge→ Finished product

Detailed Images

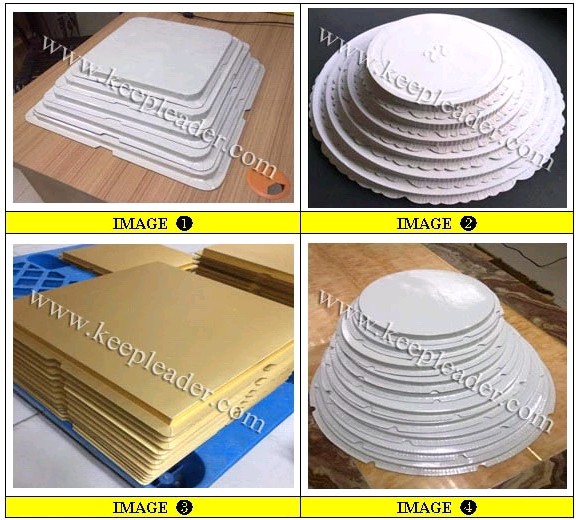

KEEPLEADER has stocked "Cardboard cake box bottom forming machine", welcome to vist our displayed samples

Product Uses

Produced samles of "Cardboard cake box bottom forming machine" And produced samples of "Paper cake box edge curling machine"

FAQ

ABOUT PRODUCT

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

Cardboard cake box bottom forming machine

KEEPLEADER has paper cake box edge curling/forming machine, paper cake box base/bottom/tray forming machine

Contact Us

About "Cardboard cake box bottom forming machine" & " cardboard cake box edge forming/curling machine" pls contact keepleader

☺ Attn: Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone/Whatsapp:+86 13590415784

☎ Tel:+86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader