Industrial Parts Cleaning Ultrasonic Cleaner of Water Bath Sonicator Ultrasonic Cleaning Machine for Metal Parts Washing Bath

Industrial Parts Cleaning Ultrasonic Cleaner

You can count on KEEPLEADER Industrial Parts Cleaning Ultrasonic Cleaner to remove oil, grease, dust and other stubborn dirty, our solution give you cleaner parts with less effort, from table top to large-capacity units to accommodate casual to heavy users and parts of any size

Product Description

Industrial Parts Cleaning Ultrasonic Cleaner

01: Application

Industrial Parts Cleaning Ultrasonic Cleaner can be used for many applications, including plastic parts, bearings, bolts, rubber parts, internal parts, plastic injection molds, transmission parts, engine parts, electronic parts, Industrial Parts Cleaning Ultrasonic Cleaner can also be customized to suit the specific needs of a factory, hospital or other business, with thousands of commercial and industrial cleaning applications, Industrial Parts Cleaning Ultrasonic Cleaner is tailored to the types of parts that they are cleaning, table top and bench top cleaners, for example, are best for cleaning small or delicate parts like bearing, surgical instruments, optical parts, machined parts, small gears and carburetor components, precision cleaning is used for cleaning and restoring delicate items that may have been damaged by traditional cleaning methods

02: Parameter

Industrial Parts Cleaning Ultrasonic Cleaner | ||||||

Model | Sonic Power | Inner Size (mm) | Volume | Frequency | Vibrator | Heat Power |

KLE-1018 | 900 W | 500*300*250 | 38L | 40/28KHz | 18 | 1.5kw |

KLE-1030 | 1500 W | 500*350*300 | 53 L | 40/28KHz | 30 | 1.5kw |

KLE-1036 | 1800 W | 550*400*350 | 77 L | 40/28KHz | 36 | 3kw |

KLE-1048 | 2400 W | 550*450*400 | 99 L | 40/28KHz | 48 | 3kw |

KLE-1048 | 2400 W | 800*300*400 | 96 L | 40/28KHz | 48 | 3kw |

KLE-1060 | 3000 W | 600*500*450 | 135 L | 40/28KHz | 60 | 4kw |

KLE-1072 | 3600 W | 700*500*500 | 175 L | 40/28KHz | 72 | 6kw |

KLE-1090 | 4500 W | 800*600*550 | 264 L | 40/28KHz | 90 | 6kw |

KLE-10108 | 5400 W | 1000*600*600 | 360 L | 40/28KHz | 108 | 9kw |

KLE-10150 | 7500 W | 1000*900*600 | 480 L | 40/28KHz | 150 | 18kw |

KLE-10216 | 10800W | 1200*1000*800 | 960 L | 40/28KHz | 216 | 24kw |

03: Advantages

Ultrasonic cleaning saves time and money

Life of parts is extended due to gentle cleaning

High effective cleaning all contaminants

Various size of cleaning tank for different shape, measure of cleaning object

Automatic control system can be integrated with production line

Grated bins to hold the cleaning basket for convenient transmission

Fully insulated stainless steel tank

Equipped with low liquid level sensor

Illuminated control panel

Hinged or removable stainless steel cover

Four casters for portability

04: Buying guides

041:Following information necessitate selecting a suitable Industrial Parts Cleaning Ultrasonic Cleaner

Soils to be removed

Current cleaning method used

Materials from which your parts are manufactured

Size, weight, configuration, and quantity of the parts to be cleaner per day

Operations immediately before and after cleaning

Preferred method of handling manual or automatic

Single or multi-step cleaning required

Type of cleaning fluid solvent or water based

Budget on the cleaning procedures in your production

042: Pre- and post cleaning steps for Industrial Parts Cleaning Ultrasonic Cleaner

Pre- and post-cleaning steps are summarized because in many instances in need to perform these operations is governed by accepted good manufacturing practices

Grossly contaminated parts should be scarped or pre-cleaned with high-pressure water to cut down on introducing contaminants into the cleaning parts

Post-cleaning steps such as the removal of cleaning solution residues can be accomplished by spray wash, by immersion in a standard rinsing bath, an ultrasonic rinsing bath or by several of these steps

Products can be flash dried by hot air or placed in electric drying ovens

043: Description of Industrial Parts Cleaning Ultrasonic Cleaner

Ultrasonic frequency determines the size of the vacuum bubbles that implode and do the cleaning, the lower the frequency the large the bubble (though you can not see the difference with the naked eye), lower frequencies implode more violently that higher frequencies and are generally sued for removing contaminants from industrial parts, higher frequencies implode less violently and preferred of delicate parts, and parts with high finishes

044: How to determine the tank size of Industrial Parts Cleaning Ultrasonic Cleaner

Purchase a ultrasonic cleaner that will accommodate the largest parts you will be cleaning, know the weight of parts being cleaned, this will determine if they are cleaned in baskets are suspended from overhead or rest on racks built into the tank bottom, don’t overload the bath-efficiency drops off, much better to do several smaller batches that one large batch, for tank with weirs, be aware that the weir must accommodate the volume of liquid displaced by the parts, as a general rule the volume of parts should mot exceed 30% of the tank volume, for best results parts should not be in contact with each other, parts must not rest on the bottom of the tank, unless that tank has racks to allow this, an important consideration is what is called the working depth of an ultrasonic cleaner, this is defined as the distance between the basket bottom or bottom rack and the surface of the cleaning solution, it is important because, as noted above, parts must be fully immersed for effective cleaning

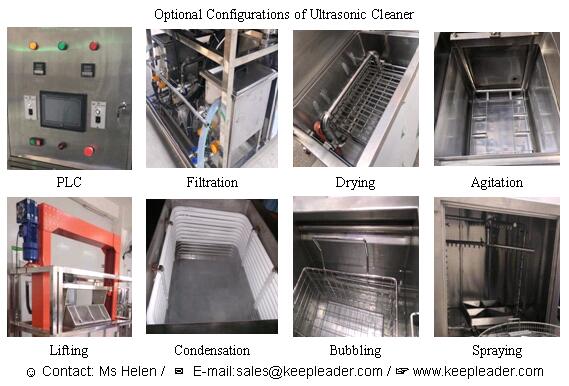

Functional Option

KEEPLEADER Industrial Parts Cleaning Ultrasonic Cleaner vary in size, configuration for functional solution for different solution to match your specific cleaning challenges

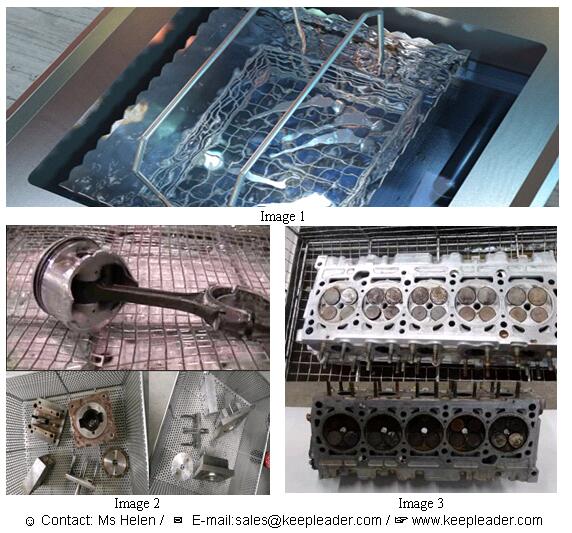

Product Uses

Industrial Parts Cleaning Ultrasonic Cleaner in the markets of aerospace and aviation, automotive and transportation, industrial machines, medical equipment, metal finishing, printing and 3D printing, specialty cleaning, tooling and machining applied for Disaster recovery, industrial manufacturing, cleaning and degreasing industrial parts, light-duty vehicle and heavy equipment mechanics, equipment and tool maintenance, cleaning molds, refurbishment and repair workshops, polishing and metal finishing

Contact Us

KEEPLEADER teams are constantly improving our designs to keep our Industrial Parts Cleaning Ultrasonic Cleaner at the cutting edge of the ultrasonic cleaning industry. And we offer dedicated technical service to each and every KEEPLEADER client. In addition to putting our customers first, we are fully committed to environmentally friendly practices, we know the method and machinery you use may be what sets your company apart from its competitors, so removing unwanted and unseen residue is of paramount importance, we take this to heart and strive to provide our customers with the best and most affordable Industrial Parts Cleaning Ultrasonic Cleaner on the market, please contact KEEPLEADER for updated information of ultrasonic cleaning solution

☺Attn: Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone/Wechat/Whatsapp: +86 13590415784

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader