HF Welder Heat Sealer for PVC Tent Canvas Tarpaulin High Frequency Welding Machine of Truck Cover_Oil Booms_Tensile HF Welding

HF Welder Heat Sealer for PVC Tent Canvas Tarpaulin

HF Welder Heat Sealer for PVC Tent Canvas Tarpaulin is optional configuration in #1: HF Power #2: Trough Depth #3: Throat Depth #4: Dimension of Electrode #5: Stroke Distance

Machine Description

HF Welder Heat Sealer for PVC Tent Canvas Tarpaulin

01: Application

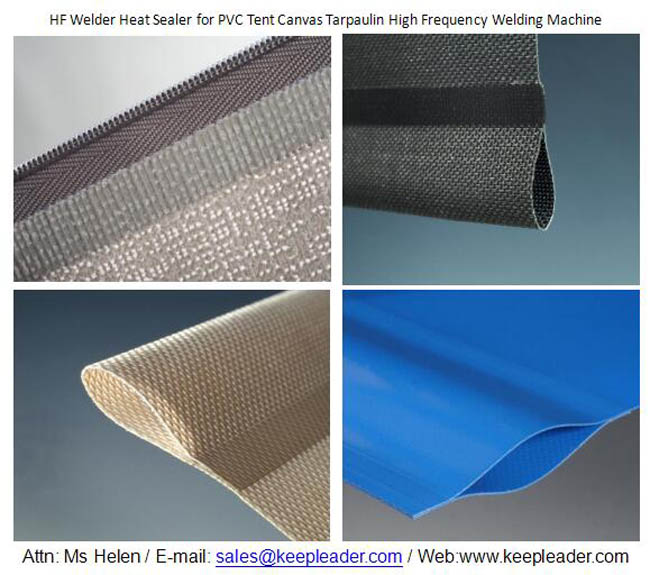

HF Welder Heat Sealer for PVC Tent Canvas Tarpaulin is popular used for flexible products made of PVC,PU,TPU, applied for air, water tight seam sealing, targeted for storage, screen shield, covering, signing and advertising

Advertising signs, and large format billboards

Small and large format technical textile PVC or PU coated

Tensile structures, tents, shade systems, truck covers and side contains

Swimming pool liners and covers, oil booms, flood dams and water tanks

Airport hangars, portable storage structures, containment pools, ground liners

02: Parameter

Name | |

Model | KLR-5KW-SN |

HF Power | 5000W |

Input Power | 8KVA |

Heating Power | 500~1000w |

Power Supply | 220V/350V, 50Hz/60Hz |

Electrode size | 600*250mm |

Stroke Distance | 150~200mm |

Spark detective device | NL-5557 |

Oscillator tube | 7T85RB |

Welding Pressure | 300~500w |

Welding Time | 1~5 Seconds |

Net Weight | 600kgs |

Gross Weight | 650kgs |

Packing Dimension | 130*111*212cm |

03: Advantages

Welding current limit meter read in tuning basing on auto base

NL-5557 Anti-sparkle device to protect the machine for overload

Curved HF electrode is available for sealing round window profile

frame rolled steel structure for excellent strength and work ergonomic

Equipped with laser scan light to guide the seam line in overlap process

With deep and wide trough behind the electrode for material storage and handling

Manual and auto model optional for convenient debugging, maintenance and operation

Heating device with thermostat concerned in HF impulsing seam is additional function

Smooth glide wheel for each movement in-ground welded fabric or relocation desired place

Product Uses

HF Welder Heat Sealer for PVC Tent Canvas Tarpaulin can weld Flexible Products Made of material: PVC, PU, TPU. PE or coated

Tech Support

In order to preserve the longevity of HF Welder Heat Sealer for PVC Tent Canvas Tarpaulin, maintenance is key, when a HF welder goes down, there can be serious ramification such as halts in productivity leading to a loss in profit, this is way KEEPLEADER has created a checklist that outline the preventative measures you can take on a daily to a yearly basis to ensure that HF welder is running smoothly, as a disclaimer, before any maintenance is carried out ensure that it is in a safe condition and that services are switched off and isolated, always short capacitors and components to earth before touching, our HF Welder Heat Sealer for PVC Tent Canvas Tarpaulin has main power switch, and separated power switch on operation panel, if want enter inside to repair or maintenance, must close the main power switch, and close the input power source, which is for double safe consideration, never use wet or oil rags when cleaning HF welder, instead use denatured alcohol, below you will find a tried and true outline for HF welder maintenance

Daily Maintenance

Wipe the table down every morning

Keep the area around the HF welder clean from debris

Inspect the electrode bar for cleaning without melting residues

Listen the oscillator cooling fan is working

Inspect any visible damage outside

Lubricate the mechanical parts

Monthly Maintenance

Inspect the earth connection platen

Inspect the pneumatic supply

Inspect the power wire and components are connected without any loose

Periodic Maintenance

Heating element, thermostat

Parallel electrode holder and platen

Ensure earth connection are in good condition

Check for cracks or discoloration

Yearly Maintenance

Remove all panels and clean inside of the machine

Inspect the wire earth connection (replace if damaged)

Inspect electrode and earth platen (replace if damaged)

Inspect air pressure regulator for leaks

Clean interior of generator cabinet

KEEPLEADER also offers a comprehensive preventative maintenance program that includes adjustments to the HF Welder Heat Sealer for PVC Tent Canvas Tarpaulin, cleaning of surfaces, enhanced training on specific applications and customized manual for ongoing maintenance, if you have any questions about our maintenance programs, you can contact our tech staffs to learn more

Contact Us

☺ Attn:Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone/Wehat/Whatsapp:+86 13590415784

☎ Tel:+86 755 84190358

☞ Website: https://www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader