Servo Motor Spin Welding Machine for PP Mug_PE Pipe_Filter_PP Cup Spin Friction Melting Welder of Servo Orientating Spin Welder

Servo Motor Spin Welding Machine

Servo Motor Spin Welding Machine is #1: servo motor drived for #2: Orientation in rotary degree +1

Product Description

Servo Motor Spin Welding Machine

01: Application

Servo Motor Spin Welding Machine is a method of joining plastic components together with surface friction concentrated in a circular weld joint, one part is spun relative to another and force is applied, causing the material to heat and melt, the spinning process stops and parts continue to be pressed together while they bond

Servo Motor Spin Welding Machine or orientation spin welding has several additional benefits over inertial spin welding, the main benefit is the ability to stop the part being welded at a specific point during its 360 degree of rotation and index to a specific spot with respect to the mating part with an accuracy of ±1 degree, also this indexing is available at both ends of the stroke, at the head up position, the driver can be rotated to any position for loading purpose or part pick up, making it ideal for automation application

Another benefit of servo motor spin welding machine is that there is no need to store energy or inertia in a spinning flywheel because of the torque generated by the servo drive motor, so it is possible to contact the part with the driver and to apply pressure to the part before rotation begins to either compress or align the two mating parts before welding, the circumference speed calculation found in inertial spin welding don’t apply to orientation (servo) spin welding

With servo motor spin welding application is also important to have the appropriate conditions for spin welding success along with sturdy driving features to allow for proper orientation

02: Parameter

Name | Servo Motor Spin Welding Machine |

Model | KL-2900 |

Servo-Motor Power | 2.9kw |

Power Supply | AC 220V/380V, 3P, 50Hz |

Motor Speed | Max 1500 RPM |

Rotation Circles | 30 (adjustable) |

Delay Time | 0~100 seconds (Adjustable) |

Hold Time | 0~100 seconds (Adjustable) |

Working Pressure | 0.5~0.7Mpa |

Torsion | 10N*M |

Gross Weight | 350kgs |

Dimension | 900*700*1900mm |

03: Character and advantages of servo motor welding

Position-based indexing possible

Requires less velocity (better for engineering resins)

Improved process control

Heat confined to weld interface

Compatible with most thermoplastics

Ideal for welding of PP and PE materials

Ability to weld several dissimilar materials

No consumables, fumes, or emissions

High strength, hermetic welds are typical

Password protection of setup parameter

Relatively fast cycle times when compared with other methods

Low power consumption, low maintenance and quick change tooling

Up to 150,, stroke for greater versatility and easier part load and unload

High precision servo spin driver with orientation accuracy of +/- 0.1 degree

Ability to weld parts with circular joint that are not easily welded by ultrasonic

Programmable welding methods include weld by time, rotation circles, speed and orientation

Aggressive jointing method

High-strength welds

Hermetically sealing joints

Cost-effective for round weld joints

04: Servo Motor Spin Welding process steps

Head Down: upper spin driver moves downward (typically without rotation) until the part halves make contact

Spin: Upon contact, a slight delay occurs to insure parts are seated properly and rotation is maintained at the user programmed RPM until the programmed number of revolutions and final axis of rotation (degrees) of the weld is achieved, if orientation is not required, user many program RPM and one of the following: a)time, b) collapse distance, c) absolute distance during the weld.

Hold/cooling: pressure is maintained on the part after rotational welding motion has ceased, allows thermoplastic material to solidify, ensuring the optimum bond of the two part halves

Home: Servo motor rotates back to its indexing or home position automatically

Touch screen with intuitive menu structure

Product Uses

Servo Motor Spin Welding Machine is advanced in PP,Nylon low viscosity resin polymer of circular joint hermeric bonding

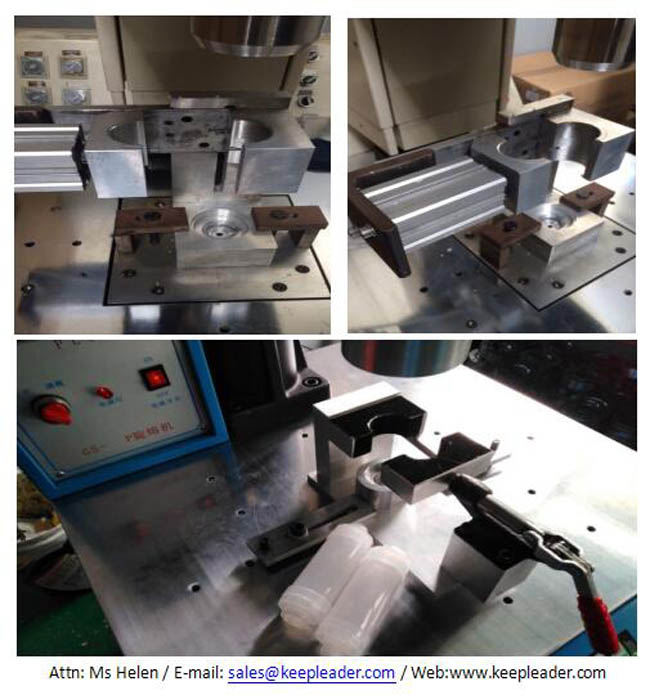

Tooling Images

Servo Motor Spin Welding Machine is optional in #1: Manual Fxiture #2: Pneumatic Fixture combined with elastic lined actuator

Contact Us

Servo Motor Spin Welding Machine is Servo orientaion based model, keepleader also has inertial based for option, please contact us for more information

☺ Attn:Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone/Wechat/Whatsapp:+86 13590415784

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader