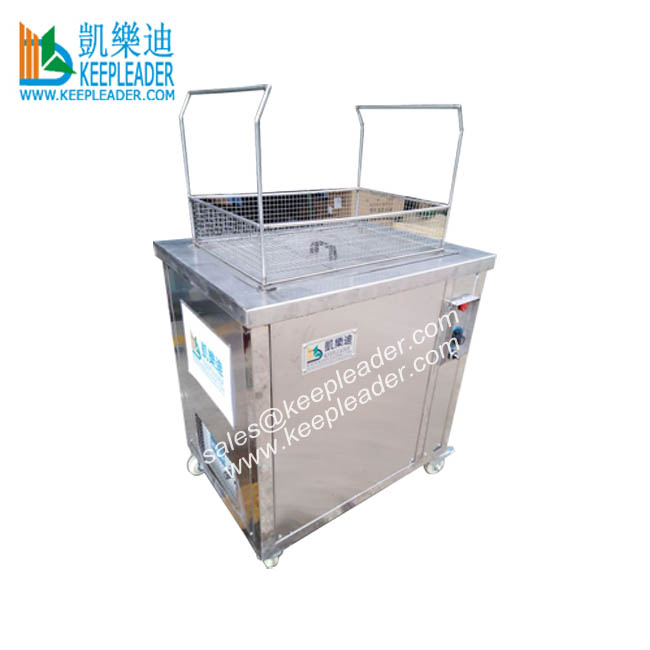

Carb Cleaner Ultrasonic Carburetor Cleaning Machine of Greasy Motorcycle Carbs Ultrasonic Cleaning for Carburetor Restoration

Carb Cleaner Ultrasonic Carburetor Cleaning Machine

Carb Cleaner Ultrasonic Carburetor Cleaning Machine has become the most popular way of carburetor/curbs cleaning in restoration, especially when it comes to complex carburetors and other sensitive automotive parts, engine components

Machine Description

Carb Cleaner Ultrasonic Carburetor Cleaning Machine

01: Application

Carb Cleaner Ultrasonic Carburetor Cleaning Machine is a strong, accurate yet gentle cleaning method that makes practical use of phenomenon call cavitation, the term refers to the action of bubbles in the liquid that are subjected the strong levels of pressure variation at the curtain hz range, Carb Cleaner Ultrasonic Carburetor Cleaning Machine has two popular hz range: 28khz and 40khz, or dual frequency in one machine, when large changes o pressure and vibration pass through a liquid, the condition creates tiny bubbles that rhythmically implode into extreme shock-waves, process generated by this implosion can be significant enough to dislodge grease, varnish, fuel gel rust or other stubborn deposits, the carburetors and other related engine parts on power-sports motorcycles, ATV or UTV’s are mostly mechanical devices designed to achieve precise fuel-air mixtures from their internal combustion engines, they are built of valves, chambers, floats, bowls, jets and other intricately designed components placed together in delicate balance, when carburetor parts become plugged, varnished, greasy and coated with soot from extended use, it can result in difficult starts, poor power delivery, and fuel inefficiency, soot-filled exhaust, timing sneezes and overheating, cleaning carburetors and other engine parts require the ability to clean all surfaces o the component thoroughly

02: Cleaning procedures

Carefully place the basket with carburetors, engine parts in the ultrasonic cleaning tank, fill the tank with mixture of distilled water and cleaning concentrate at designed rate, fully submerge carbs for cleaning in the solution, set the desired cleaning temperature and activate the tank heater, wait for liquid in tank to reach set temperature, and than set ultrasonic timer, in accordance with requirements of cleaning process, depends in the type and degree of contaminants of cleaning carburetors, once cleaning is complete, wait for liquid to cool down and then carefully remove basket with carburetors, rinse carbs with clean water, change bath regularly when the solution becomes dirty

03: Parameter

Name | |

Model | KLE-1024 |

Internal Tank size | 590*400*400mm |

Ultrasonic Power | 1200w |

Vibrators quantities | 24pcs*50w/pc |

Power Supply | 110v,60hz or 220v,50hz single phase |

Ultrasonic frequency | 28khz or 40khz |

Heating Power | 2kw |

Heating elements | casting Aluminum |

Auxiliary | Cleaning basket and tank lid |

Net Weight | 130kgs |

Gross Weight | 180kgs |

Overall size | 720*500*600mm |

04: Character and advantages

Steel tight-fitting lid with handle

1~30min adjustable timer settings

2kw heating power, and 1200w ultrasonic power

High quality durable stainless steel construction

Drainage built-in for convenient cleaning ultrasonic bath

Moisture-proofed and anti-corrosion ultrasonic generator for enhanced cleaning

Time saving: carburetor components are cleaned faster, only water-based chemistry used and partial dismantled in cleaning process

Gentle cleaning: unlike traditional cleaning methods where abrasion plays a significant role in stain removal, ultrasonic cleaning depends entirely on sound waves which causes the molecular scrubbing action and no abrasion is involved, this is vitally important because components wear and tear is greatly reduced

Wide range of contaminants removal: since carburetors are prone to a variety of chemicals and dirty, Carb Cleaner Ultrasonic Carburetor Cleaning Machine offers a tremendous level of flexibility when it comes to stain removal

Convenience and efficiency: with Carb Cleaner Ultrasonic Carburetor Cleaning Machine, it is possible to clean every part of the engine easily, in fact, one only needs to dip the parts to be cleaned into the ultrasonic tank, turn the ultrasonic sound generator on, and use the right ultrasonic cleaning detergent, you will quickly notice that not only large debris is removed from the carburetor, but also, extremely tiny debris

05: Tips for cleaning carburetors

Mix the concentrated carburetor cleaning fluid with water at ration of 10:1 (10 parts water to 10 parts cleaning fluid). for heavily soiled components, the ration can be strengthened to 7:1, the working temperature on the ultrasonic cleaner should be between 50~80 degrees centigrade, after cleaning, rinse the carburetors with clean water and leave to dry, if the contaminants are heavy, prepared cleaning by rubbing, spraying before ultrasonic cleaning is recommended, for robust and harden debris trapped inside of carburetors or other engineer parts, prior to ultrasonic cleaning, immersible cleaning to soften rugged dirties is necessitated

After you are pulled the carburetor, make sure it is free of gas, twist it around, blow it off and give it a quick once over, you don’t want any gasoline contaminating the process

Brush off any loose dirty and grim, and give the carburetor a quick blast, this is not so much to clean the carburetors, but it is really to keep the ultrasonic cleaning fluid free of crud

Take of all the gasket, seals and any rubber, you will probably be replacing all these things anyway, so why bother to clean them? Even if you don’t replace them take them off so the carburetor gets max exposure to the ultrasonic

Remove the float bowls, you want as much of the carburetors’ internal guts exposed to the ultrasonic cleaning fluid as possible, removing the floats help the cavitation get all the nooks and crannies inside the carburetor

Put the carburetor in the ultrasonic cleaning machine for about two minutes, and then pull it out and check it, you want to make sue that the parts are all aluminum alloys, sometimes, if a carburetor has other alloys like nickel, the ultrasonic can blacken and pit the metal, you just want to be sure you know what you are working with

Don’t overload the ultrasonic cleaning, just because of you have a big tank does not mean should jam it, full of parts, make sure there is good space around each carburetors you put in the tank, if you lay them in top of the other, the ultrasonic cleaning machine doesn’t work the way it is supposed to

Choose the right fluid, it is not only the cleaning action of the fluid, but the fact that you can get non toxic

Detailed Images

Carb Cleaner Ultrasonic Carburetor Cleaning Machine is popular model with based configuration, keepleader also accept custom ultrasonic carburetor cleaning with optional features in #1:Complete thermal insulation #2: laminar flow separation system #3: filter recirculation #4: frequency flushing #5: program automation #6: elevator tray #7: Stop & Go

Product Uses

Carb Cleaner Ultrasonic Carburetor Cleaning Machine not only does carburetor cleaning reduces the overall time and money spend on cleaning carbs/engine components/automotive parts, but also it helps to delivery the best remarkable and reliable results that have never been attained with other cleaning agents

Contact Us

When Carb Cleaner Ultrasonic Carburetor Cleaning Machine comes into your consideration, please tell us your preferrable considers in #1: Internal size of cleaning tank #2: Maximum Loading weight #3: Auxiliary Function your preferred #4: Purchasing budget

☺ Attn:Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone:+86 13590415784

☎ Tel:+86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader