Wire Bonding Ultrasonic Metal Welding Machine of Nickel_Aluminum_Copper Wire Soldering Metal Wire Splicing Ultrasonic Welder

Wire Bonding Ultrasonic Metal Welding Machine

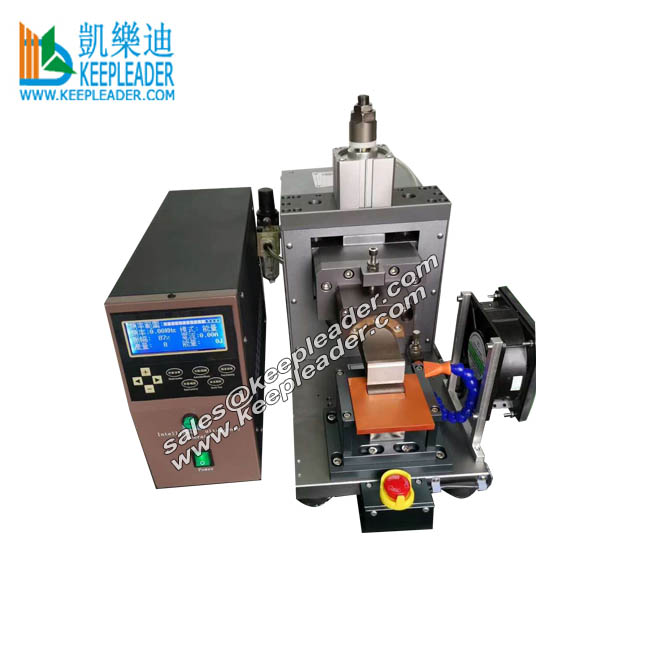

Wire Bonding Ultrasonic Metal Welding Machine has computerized ultrasonic generator, pneumatic clamping device and pneumatic pressing system for metal wire_sheet_wire terminal bonding in various size and shape

Machine Description

Wire Bonding Ultrasonic Metal Welding Machine

01: Application

Wire Bonding Ultrasonic Metal Welding Machine is the future oriented method for wire and terminal application, Ultrasonic Metal Welding Machine is a new industrial ultrasonic wire splice solution, it welds stranded, braided and magnet wires to create a wire splice, wire crimp or a battery cable splice, the connection of Wire Bonding Ultrasonic Metal Welding Machine is reliable welding solution in the automotive, aircraft, computer and consumer electronics industries, as well as other process control and industrial instrument application, ultrasonic metal welding machine is most commonly used in the production of wire harnesses, compared with crimping or resistance welding, Wire Bonding Ultrasonic Metal Welding Machine offers numerous advantages, besides the excellent electrical properties of the joint and the extremely low energy consumption, this method is particularly characterized by comprehensive process control and process data management, Wire Bonding Ultrasonic Metal Welding Machine usually has following scopes

011: Multi-layer positive and negative electrode welding for dynamic power battery

012: Welding material does not melt, non-fragile metal properties

013: Li-ion battery and polymer battery: copper foil welds nickel sheet; aluminum foil welds aluminum sheet; aluminum foil welds nickel sheet

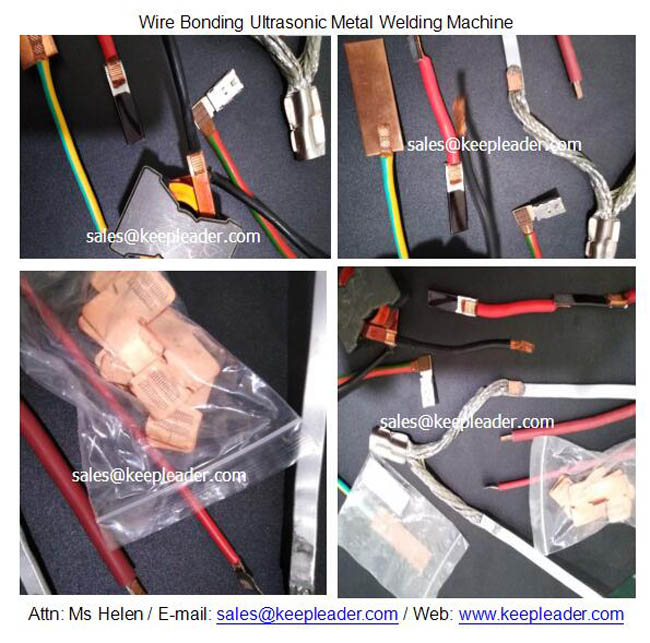

014: Auto splice welding, formation of electric wire end,welding for electrical wires, multiple electric wires bond welding

015: Electric wire and cable welding, terminal, connector, electric parts welding

016: Solar panel battery, flat solar plate, copper and aluminum plate joints

017: Solenoid switch: big currency joint point welding and dissimilar metal welding

018: refrigerator and air conditioner copper tube sealing, vacuum parts of copper tube and aluminum tube sealing

019: copper wire, aluminum wire,such as copper and aluminum wire harness, metal braided wire, metal stranded wire, wire harness terminal, enameled wire, motor lead wire and etc

02: Parameter

Name | |

Model | KLM-3220 |

Ultrasonic Power | 3200w |

Ultrasonic Frequency | 20khz |

Used for | Metal wire and Metal sheets |

Max welding size | For wire splice: 0.5~20mm2/For Battery Foil layer: No. 80 layers |

Productivity | 15~30pcs / Min |

Welding Speed | 0.01~9.99 seconds |

Pneumatic pressure | 0.3~0.6 Mpa |

Driven mode | Pneumatic |

Weldable material | Aluminum, Copper, Sliver, Gold, Nickel and etc |

Net Weight | 60kgs |

Input Voltage | 110v,60hz or 220v, 50hz singe phase |

03: Advantages of ultrasonic metal welding

Oxidation or plating metal can be welded

No welding sparks, environment protection and safety

Good conductivity and resistivity very low or almost near to zero

Keep the metal metallic character, good conductivity, low electrical resistivity

Short welding time, no need additional flux, gas, solder or other additional consumption

Without the need for frequency replacement of amplifier due to consistent adjustment of the amplitude

04: Character

Easy installation and operation

Overheating, overloading double protection system

Automatically adjust the output power according to load

Process optimization using a wide range of welding parameters

Touch screen and digital parameters setting easy to operate and easy to learn

High anti-interference ability, time accuracy is up to 0.01 second and easy to adjust

The wires are mutually melted, entangled into one and a plurality of mutually melted

Fast and efficient production process, low energy input and high degree of quality monitoring

New type of power amplifier circuit with stronger power and more durable transducers with advanced piezoelectric ceramic

Frequency automatic tracking,tuning and real-time display the current frequency, no need to manually tune and can automatic tracking the best working state

Mahine Uses

Wire Bonding Ultrasonic Metal Welding Machine is appropriate for the assembly of similar and dissimilar non-ferrous metals, suitable for welding copper wire and aluminum wire, such as copper and aluminum wire harness, metal braided wire, metal stranded wire, wire harness terminal, enameled wire. Motor lead wire and etc

Contact Us

keepleader is engaged in building Wire Bonding Ultrasonic Metal Welding Machine in prominent stage, clear in deep heart that the stop comes with lost, best wishes for any cooperation with our practical accumulation around the world, let us know your expectation in metal bonding process to find what can we do for you

☺ Attn: Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone:+86 13590415784 (Wechat/Whatsapp)

☎ Tel:+86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader