Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning of Hardware_Metal Parts Ultrasonic Bath

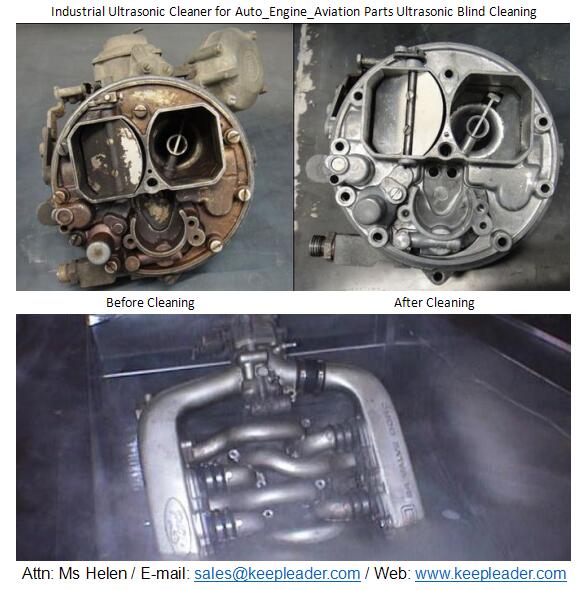

Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning

Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning has cleaning size/basket size made as your demanding applied for your delicate metal parts cleaning with ultrasonic vibration scrubbing

Machine Description

Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning

01:Application

Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning can clean delicate parts, engine, auto parts, and aerospace, electronic components thoroughly without harsh chemical or damaging abrasives, this is achieved with a process called “cavitation”, cavitation is the creating and implosion of microscopic bubbles in the solution created by transducers, stud bonding to the beneath or side of stainless steel tank, the ultrasonic transducer produce a frequency through the solution, this combined with heat and a cleaning solution specific to the cleaning task result in a very thorough cleaning process that will penetrate into the tightest space invisible to the naked eye, in industrial production, the prominent demanding on removing the contamination of delicate parts play a exclusive role for Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning

02:Parameter

Name | Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning |

Model | KLE-1036 |

Vibrators | 36pcs |

Ultrasonic Power | 1800w |

Power Plug | 110v/220v/380V |

Ultrasonic Frequency | 28khz or 40khz |

Heating Power | 2~4kw |

Material | SUS304/SUS316L |

Tank Capacity | 180L |

Timer | 1 thru 30min adjustable |

Timer style | Mechanical tuner |

Temperature | 20~80 degree adjustable |

Cleaning Mode | Sweep |

Internal size | 600*600*500mm |

Net Weight | 150kgs |

Gross Weight | 180kgs |

03:Character

2~4kw heating power for quickly pre-heating applied

Bonding transducers guaranteed for 10 years

Thermostat optimizes tank temperature to 60 degree

Corrosion-resistant welded stainless steel construction for longevity

Double walled insulated tank and lid to prevent heat loss

Equipped with stainless steel basket

Suitable for a long time and continuous running more than 24 hours

Independent ultrasonic generator makes industrial cleaning stable and effective

Professional mesh cleaning basket makes cleaning effective and easy

Bonding transducers guaranteed for longevity not less 10 years

316 grade stainless steel lift off lid with handle for easy and safe access to parts being cleaned

Sound deadening insulation package to reduce nose emitted from the ultrasonic cleaner

Illuminated controls for ultrasonic and heater function, easy to see display to control frequency setting and to manipulate heat of the tank

04:cleaning sequence

041: Pre-cleaning and hot degreasing: complete removal of various forms of surface contamination by means of ultrasonic and hot cleaning solutions

042: Rinsing, crease/cleaning, solution removal: rinsing of residual grease/dirt and cleaning solution from the component to avoid cross contamination of subsequent bath

043: Corrosion removal: complete removal of the corrosion at 55 degree using ultrasonic and gentle, slightly acidic complex de-ruster, suitable for hardened or polished surfaces

044: Rinsing and acid neutralization: residual acid and removed corrosion residue are rinsed off, preparing for the final step

045: Water displacement and preservation: water displacement and passivating agents ensure that the metal surfaces do not rust upon exposure to air

05: Highlighting of Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning

There are a number of benefits realized from the application of industrial ultrasonic cleaner for Auto_Engine_Aviation Parts

051: Enhanced cleaning speed: ultrasonic is faster than any conventional cleaning method, entire assemblies can be cleaned without disassemble

052: Often the labor-saving advantages make ultrasonic the most cost effective choice

053: Unmatched cleaning consistency: the ultrasonic activity is micro in nature and reaches all areas for uniform cleaning, this is true for large or small parts, simple or complex parts handled singly or in batches, thorough soil removal is not operator dependent

054: Easier compliance with safety and environmental regulation through reduction of dangerous chemical concentrations or substitution of less aggressive cleaning media

055: reduction of direct worker contact with hazardous cleaning substances

056: Saving in energy costs, labor and floor space

In addition to the mechanical advantages provided by ultrasonic, there are a number of chemical or process benefits which can also be gained

057: Speeding up the rate at which soil dissolves by intimately mixing the cleaning agent with the contaminants

058: Carry fresh solution to the soiled surface through a “micro-streaming” effect

059: attacking the molecular “cement” by which soil attaches itself to cleaning surface

0510: Preventing formation of a neutral film on the cleaning surface that may impede cleaning

0511: Raising the temperature of the liquid, thereby increasing the rate of chemical activity

Detailed Images

Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning is customized merchandise, keepleader is an industry leader, our systems are cutting edge, they feature: 1: All function in one tank #2: Multiple-stage cleaning #3: Auto elevator transfer in cleaning procedures #4: Totally closed structure #5: PLC+Touch screen of legible setting #6: Filtering Pump circulation #6: Built-in High pressure spraying wand #7: Primary water-cooling coil and Condensing Jacket of freeboard #8: Mounted close-loop filtration system #9: Designed precaution alarming system for LL Liquid detector, Reciprocation compressor, Temperature engaged #9: Reduced manipulation by automated elevator with manual spraying wand

Machine Uses

KEEPLEADER is reliable supplier in development and manufacturing Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning with features in #1: customized service #2: competitive price #3: experienced team #4: effective cleaning solution #5: Eco-friendly and creative #6: CE certificate

Contact Us

we are dedicated to providing the best Industrial Ultrasonic Cleaner for Auto_Engine_Aviation Parts Ultrasonic Blind Cleaning in the industry, find out yourself why keepleader is a leader in the ultrasonic cleaning solution and service, please contact our representatives to get more information with your question

☺ Attn:Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone:+86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: https://www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader