Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker of Plastic Tube_Heat Shrink Sleeving Hot Foil Press Printer

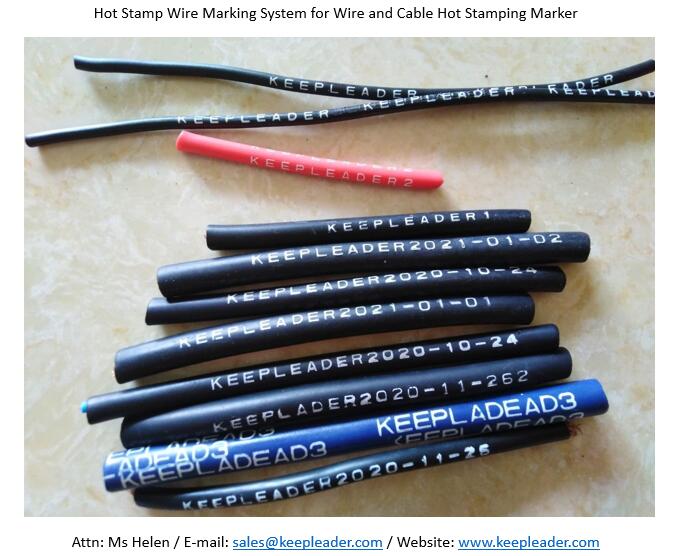

Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker

Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker is extremely tough and durable and, will not cold flow, melt or split, with our Hot Stamp Wire Marking System, characters instantly penetrate and permanently adhere toand become an integral part of the plastic insulation material, the marker is permanently marked with unexcelled clarity and legibility

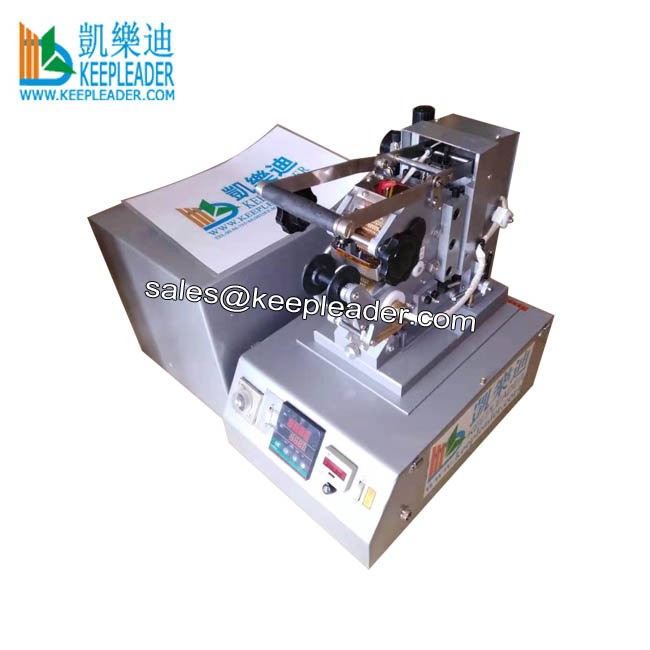

Machine Description

Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker

01:Application

Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker features wheel characters for quick change of marking codes, each printing wheel contains, the full alphanumeric character set and punctuation, and can be rotated in any combination to set the required marking code up to 40 printing wheels can be installed, with the printing wheels pre-loaded into the Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker, change-over of the marking codeis as simple as rotating the printing wheel to the desired characters,eliminating hand setting of individual type characters, and waiting for new characters to reach marking temperature, marking is possible on most wire insulations and for wire from 0.15~16mm in diameter, marking foil is availablein various colors of better contrast with wire insulation color, the end usercan select the driving modes in lever press, motorized or pneumatic driven,quantities of printing wheels and character size

02: Parameter

| Model | Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker |

| Power Supply | 220v, 50hz, or 110v, 60hz equipped with voltage convertor |

| Heating Power | 300w |

| Embossing Temperature | 50~200 degree |

| Air Supply | 5~8 Bar, consumption approx. 0.5l/Cycle |

| Qty of changeover wheel | 11pcs |

| Character in each wheel | 40pcs in read: A~Z, 0~9, . / + - |

| Character Size | 1.2, 1.5, 1.6, 1.8, 2.0, 2.2, 2.4, 3.0,3.3 |

| Wire Diameter | 1.5~16mm |

| Maximum line speed | 16m/minute |

| Maximum wheel qty | 40pcs |

| Printing Speed | Approx. 1 seconds per circle depends on the dwell time |

| Foil Consumption | Continuously variable up to 20mm |

| Foil mounting | Cassette |

| Surface treated | Flat or concaved |

| Available Material | Cable, wire, sleeve, shrink Sleeving, Plastic tubing, strands |

| Triggering system | Manual press and Pedal Valve control |

| Operation | Pneumatic/electric, remote signal operation in conjunction with in-line process |

| Wire guiding | V Shaped positioning guidance |

| Facet Read | Horizontal or Vertical if diameter less 1.5mm |

| Dimension | 350*320*500mm |

| Net Weight | 28kgs |

| Gross Weight | 38ks |

| Specification are subject to change without notice, and exceptions may apply depending on application, wire and other variables, optional equipment may require standard machine modification and/or later specifications, keepleader recommends that wire samples be submitted in case where there is doubt as to the processing capability of a particular machine | |

03: Character

Prints horizontally or vertically along wire

Utilizes full-size 40 character type wheels

Visible digital switchboard is easy to operate

Operates remotely, manually or with foot pedal

Type is standard Gothic unless otherwise specified

Lightweight, portable and inexpensive to operate

Solid base and structure, quick assess ofparts cabinet

Standard print color is black or white (other color available)

Most important changeover operations possible without tools

Rugged, heavy duty construction fo rproduction environment

Reduction in cost and time as compared to doing it manually

New, economical marking wheels available at a reasonable price

The fastest intermittent hot stamp wire printer on the market today

Shortest changeover times, don’t need to wait heating up to print

Free-selection to combined desired printing,Serialization is available

The color foils can be put in the cartridge without interrupting processing

Wire diameter 1.5~16mm can be covered with just two cable guiding anvil

CNC engraved characters of concaved or flat facet, Excellent marking accuracy

Company logo, name, specifications and any other punctuations can be marked

Optional production table for convenient and precise repositioning of marker

Quick-change fixture system minimizes set-up time and maximizes printing speed

Prints on command from virtually any wire processor, cutter, stripper or terminator

For insulated wire and cable, heat-shrink sleeving, rigid or thin-wall flexible tubing

04: Maintenance

A maintenance schedule is recommended for Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker, the hotstamping of plastic or rubber creates a residue on the device, which, when combined with high temperature, increases the rate of oxidation, keepleader’s special high temperature grease, which is proposed to apply in daily maintenance, prevent corrosion and provides lubrication, the grease is also available for purchase separately, a clean machine is a must, or you can findits supplier in your local market, please confirm its property prior toapplication

Detailed Images

As a pioneer and market leader in the field of Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker, keepleader provides its customers with innovative and sustainable solution for any situation that calls for wire and cable marking process, with our Hot Stamp Wire Marking System, you can feel confident that our machines are user-friendly and made to last, have in-built safety features and come with comprehensive instructions as well as free telephone, email or on-line support as needed

Machine Uses

Just like the many for more expensive alternatives, our CE certified Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker is made from solid steel, including lots of flexible options for printing on different shapes and surfaces, and allow you to adjust and fine tuning the setting to achieve perfect results on wire and cable identification codes imprinting process

Contact Us

Thanks to the great keepleader design, decades of practical experience and robust manufacturing processes, our Hot Stamp Wire Marking System for Wire and Cable Hot Stamping Marker is now available at highly affordable price, you won’t find such an impressive combination of affordability and quality anywhere else, please contact us to find what can we do for your business

☺ Attn: MsHelen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +8613590415784 (Wechat/Whatsapp)

☎ Tel: +86 75584190358

☞ Website:www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader