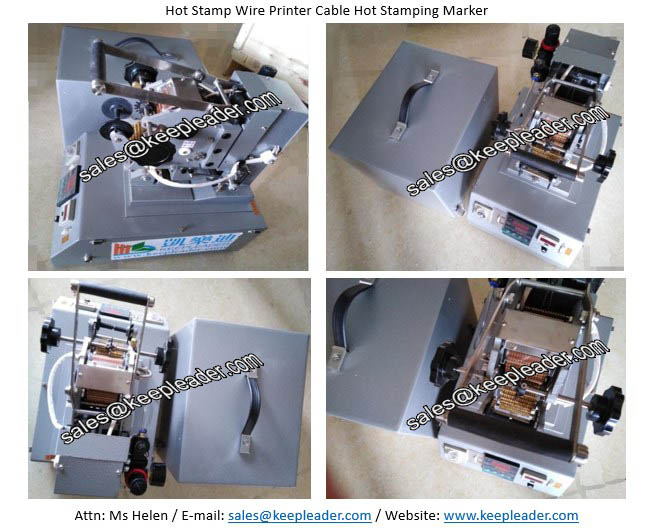

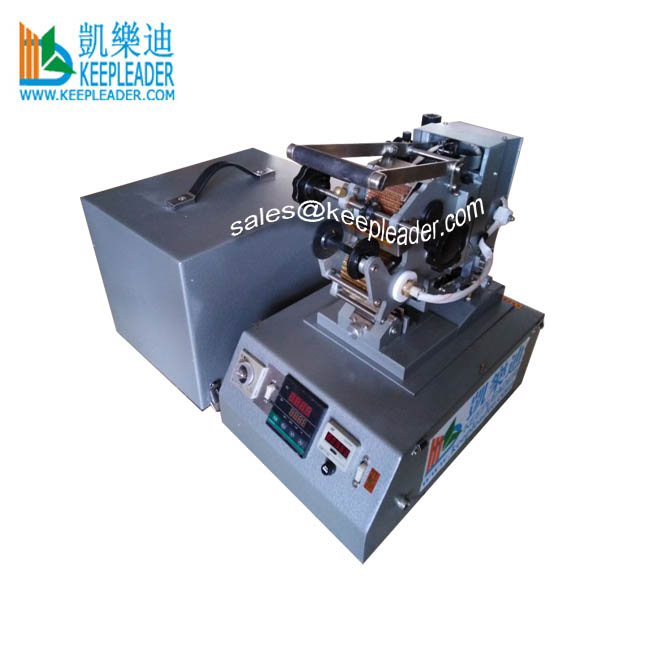

Hot Stamp Wire Printer Cable Hot Stamping Marker for Sleeve_Tube_Cable_Wire Jacket Coding_Marking_Printing_Labeling Stamp System

Hot Stamp Wire Printer Cable Hot Stamping Marker

Hot Stamp Wire Printer Cable Hot StampingMarker is an electro-pneumatic hot stamping unit used to print on wire, cables,and hoses, the hot stamping process produces abrasion-resistant markings inhigh quality, in this process a heated printing wheel packet presses printingpigment foils onto the insulation jacket of wire and cable to be printed on

Machine Description

Hot Stamp Wire Printer Cable Hot Stamping Marker

01: Application and principle

Hot Stamp Wire Printer Cable Hot Stamping Marker is a lithography printing process, electric heated rotary character wheel driven by pneumatic or servo motor to apply indenting into the surface of wire, cable or sleeve in which the pigment foil is sandwiched, this system entails using high temperature scaled 90~180 degree to transfer pigment foils to print codes, identification numbers on rubber surface of wire and cable, it is traditional solution in wire and cable marking

Hot Stamp Wire Printer Cable Hot Stamping Marker is also a dry, no-pollution imprinting solution, once the wire has been properly treated, it can withstand severe treatment, the property of pigment foil is also very important which necessitate pre-confirming its formation and trial printing result, Hot Stamp Wire Printer Cable Hot Stamping Marker encompasses mainly driven system, rotary character wheel, foil cartridge and heating elements, the electric heated engraved wheel engraved preferred characters which is pressed against the wire with marking foil sandwiched between them where the combined character in each wheel come in contact with the rubber surface of wire where the foil leaves link, the most common tools are foil and character wheels

Character wheel of each comes in quantities of 40 numbers, letters or symbols made of brass, the other pre-consideration is ink foils, which consist of a color layers, adherence base and release layer, ametallic foil will replace color layers with a layers of aluminum or chrome, it will have a metal like sheen and comes in a number of shades, including gold,silver, bronze and copper, pigment foils are upmost utilized in wire marking,which may be matte or glossy, actuator of up and down pressing is last pre-considered in lever manual press, motor driven, or pneumatic coupled

Hot Stamp Wire Printer Cable Hot Stamping Marker

02: Parameter

| Description | Hot Stamp Wire Printer Cable Hot Stamping Marker |

| Uses | Insulated wire and cable including Teflon, PVC, Tefzel, Kapton, etc |

| Model | KLS-1640 |

| Power Supply | 220v,50hz, 425VA |

| Heating Power | 300w |

| Compressed air supply | 0.7Mpa |

| Heating Control | 90~180 degree |

| Production Rate | 0.5 seconds per marking (depending on time and stroke) |

| Integral Dwell Timer | 0.1~1.2 seconds, adjustable |

| Qty of rotary wheels | 1.2~2.3mm to 44pcs, 2.5~3.6mm to 26pcs |

| Qty of characters in wheel | 40pcs |

| Fonts’ size | 1.2~3.6 |

| Imprinting Type | Vertical: 1.6mm, Flat: 3.5mm |

| Operation | Pneumatic/electric, remote signal operation in conjunction with in-line wire processor |

| Available Signs | Letters: A~Z/ Numbers:0~9/Symbols: - / . blank |

| Color | Various Foil color to contrast with wire insulation color |

| Weight | 38kgs |

| Notice: Specifications are subject to change without notice, and exceptions may apply depending on application, wire and other variable, optional equipment may require standard machine modification and/or later specifications | |

03: Buying guides

Around since the 1940s, hot stamp marking is the traditional and inexpensive solution for wire identification, this method produces very durable and legible markings and can be used on both soft and hard insulation, including Teflon

As wire is manually or automatically pulled through a wire guide, a pigment foil roll is placed between the wire insulation and heated character wheels, a pneumatic cylinder, motor driving device or manual lever as actuator to drive the characters wheels against the foil, which consists of a backing and pigment that imprints engraved characters on the insulation

Producing the best quality mark requires the correct foil, wheel temperature, pressure and dwell time, pressure is a measure of how hard the character wheel presses against the wire insulation, dwell time is the length of time the character wheel contact wire insulation

Hot Stamp Wire Printer Cable Hot Stamping Marker has two important limitations, the first is it creates an embossed imprint that could possible affect the integrity of thin insulation,another is its slow production rate, which keeps it from being used for application involving large amounts of wire, the character is also engraved in the wheel, which is fixed, cannot change after building, the barcodes is also cannot imprint, maybe, the UV laser printer or ink jetting printer is satisfied in priority

If automatic cutting, stripping and terminating machines are concerned in line with the Hot Stamp Wire Printer Cable Hot Stamping Marker, they have to stop with every marking cycle, also the text must remain the same on each wire piece until the character wheels are adjusted, either manually or automatically, but, our Hot Stamp Wire Printer Cable Hot Stamping Marker has interface to connect with your existed other wire processing machine in automatic production line, if you have this request, please confirm all of your concerns prior to ordering

04: Character

Operates remotely or with foot pedal

Utilize full-size 40 characters type wheels

Prints horizontally or vertically along wire

Additional cassettes/foil cartridge for quick foil change

The faster intermittent hot stamp wire printer on the market today

Most important changeover operations possible without tools

Shortest changeover times, and adjustable feeding length and pressing time

Compact structure has itself light for convenient shifting of printer position

Available For insulated wire and cable with connectors or terminated ends

Quick-change fixture system minimizes set-up time and maximizes printing speed

Prints on command from virtually any wire processor, cutter, stripper or terminator

05: Maintenance

A maintenance schedule is recommended for Hot Stamp Wire Printer Cable Hot Stamping Marker, the hot stamping of plastic creates a residue on the character wheels, which, when combined with high temperature, increase the rate of oxidation, high temperature grease, which is suggested for lubrication, also prevent corrosion, the grease must be high temperature resistance, which will add into the lubrication accessing port, also frequently swap the outside of machine clean by lint-free cloth, often put the wire into wire go-through guiding anvil to avoid wrong pressing down causing metal collision

Machine Uses

Hot Stamp Wire Printer Cable Hot Stamping Marker has advantages of #1: highestcontrast #2: sharp outline #3: embossed print in wire marking solution

Machine Details

Hot Stamp Wire Printer Cable Hot Stamping Marker is #1pneumaric driven up and down press, #2: pigment foil sandwiched #3:electric heated under precision control #4 radom combined character wheels in wire, cable and hoses marking application

Contact Us

Hot Stamp Wire Printer Cable Hot Stamping Marker is acceptable for modification in #1: quantities of character wheels #2: the size of each character #3: driving mode in pneumatic, servo-motor and manual lever, if you cannot find your concerned data in our weibsite, please contact us for further assistance

☺ Attn: MsHelen

✉ E-mail:sales@keepleader.com

☎ Cellphone:+86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader