Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder for Canvas_Tent 15kw High Frequency Electrode Bar Sealing Machine

Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder

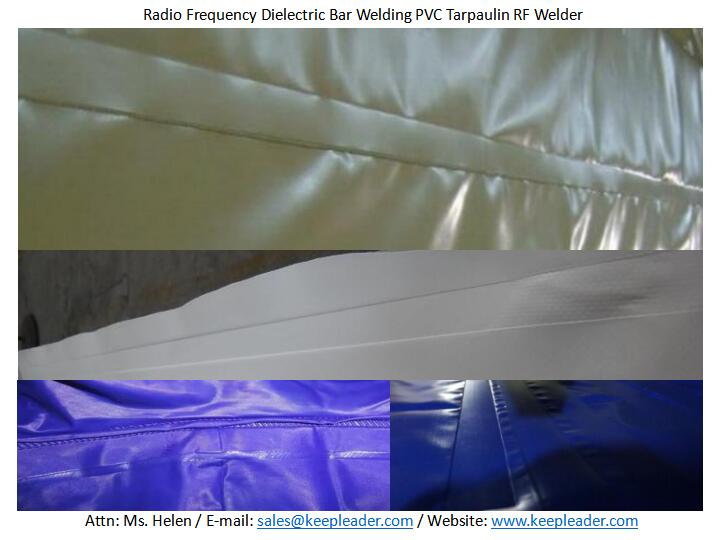

Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder makes use of high frequency electromagnetic radiation (radio waves) to excite the molecules in different types of polymers to provide highly localized heating, major advantages of RF Welder includes a consistent quality of connection and quick cooling action, material that can be used with RF welder includes polyurethane and PVC and polymers like PET, nylon, EVA, and some ABS plastic, the customized electrode bar with your desire size and shape can take performance of your versatile profiles sealing, curved or straight linear seam bonding

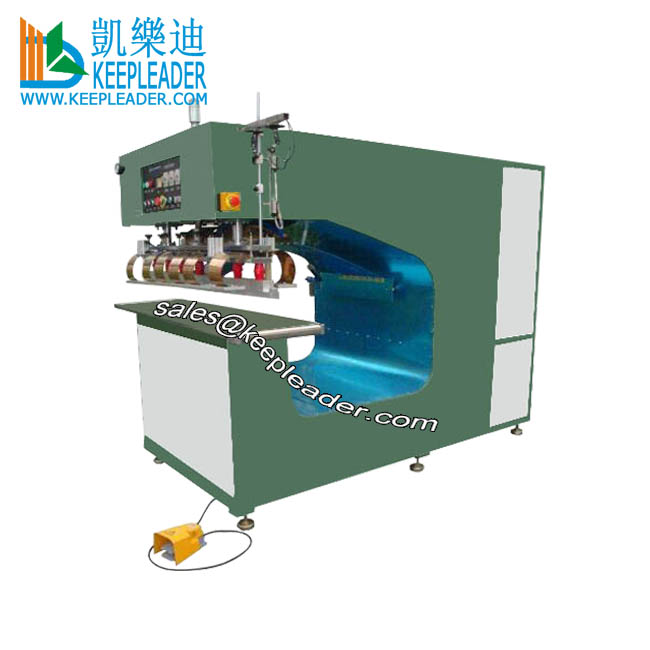

Machine Description

Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder

01: application

Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder is designed specially for production of small and large format tensile structures, membranes, tarpaulin, tents, liners, sun shading, truck covers, film containers, inflatable products, flexible door, and etc, RF welder allows to work with PVC, PU, TPU thermoplastic, and can be equipped with preheated electrode for welding non-HF weldable fabric made of PE, PP and, other non-bipolar material,RF welder can also be quipped with curved electrode for sealing round window profiles made of clear PVC or any other shaped requiring precision welding, intend to the process in performance of large-sale production, Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder also constructs deep material trough behind the electrode for storage and handling, this RF welder has optional smooth glide wheels for easy movement in-around welded fabric, or relocation to desired place

02: Principle of RF welder

Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder employs the same basic principles found in a common microwave oven, the RF welder generates radio waves that create heat inside the fabric via molecular action, the molecules that comprise the plastic are essentially flipped from a positive to negative electrical charge at a rate of several thousand times per second, this process generates friction from inside the fabric that is transmitted to the outside, the combination of the heat produced by the friction and pressure generated by the electrode bar dies creates a seal that bonds the plastic layers together, RF welder is often used to produce liner seam sealing, which is vanguard of membrane seam sealing in flexible lining, covering, shading, banning, signing, and protective packaging

03: Parameter

Name | Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder | ||

Machine Model | KLR-8KWF | KLR-12KWF | KLR-15KWF |

Welding Material | PVC, PU, TPU or coated Fabric | ||

Power Supply | 380v,50hz or 220v, 60hz Three phase | ||

Control Voltage | 24VDC | ||

Installed Capacity | 12KVA | 18KVA | 22KVA |

RF Power Output | 8KW | 12KW | 15KW |

Capacity adjustment | Manual/Auto-tuner | ||

Main Cut-out | 20A,delayed | 30A,delayed | 40A,delayed |

Operation Frequency | 27.12MHz | ||

Frequency Stability | +/- 0.6 % | +/- 0.6 % | +/- 0.6 % |

Anti-flash System | Ultra-fast sensitive ARC Sensor | ||

Air Consumption | 50nl/cycle | 60nl/cycle | 70nl/cycle |

Air Pressure | 0.4~0.8Mpa | ||

Electrode Length | 1000mm | 1000mm | 1200mm |

Work table size | 1350*700 | 1350*700 | 1620*820mm |

Pressure Plate Size | 1000*50mm | 1000*50mm | 1200*50mm |

Actuator Stroke | 150mm | 150mm | 150mm |

Electrode Drive | Pneumatic | ||

Ground electrode | Pneumatic | ||

Pressure Force | 800kgs | 1000kgs | 1200kgs |

Generator Lamp | 7T69RB | E3130 | 8T85RB |

Coolant | Cooling Fan | Cooling Fan | Cooling Fan |

Machine Weight | 800kgs | 900KGS | 1100kgs |

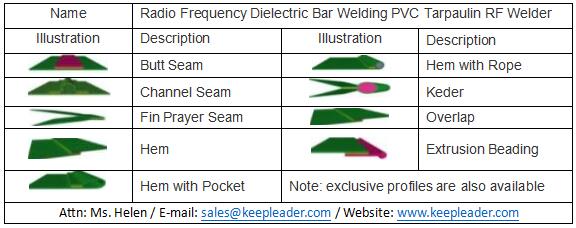

04: Available seam sealing

Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder can perform versatile seam sealing with changeable electrodes and fixtures

05: RF welding advantages

Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder presents many benefits over other welding options, these benefits include:

Environmentally Friendly:Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder does not produce smoke during the sealing process, making it an environmentally friendly option for any manufacturing operation,RF welder are “clean” because the only material needed to produce an RF weld is the material itself, there are not adhesives or by-products involved in RF welding

Minimizes the possibility of damage:most of the thermoplastic material used to produce tarp and liners offer good resistance to the RF heating technology, making the process safe and minimizing the possibility of damage

Prevents adherence of the plastic: A coating of PTFE can also applied to electrode surface to prevent adherence of the melting plastic

Superior quality:Overall, RF welder produces the best quality in terms of bonding stretch and appearance of fabric, RF heating occurs from the inside out by using the material itself as a heat source, the heat is only focused at the weld target so that the surrounding material does not have be super-heated to arrive at the target temperature at the point, with RF heat is generated only when the field is energized, once the generator cycle, the heat is turned off, this allows for greater control over the amount of energy that the material sees over the entire cycle, in addition, the HF welder heat does not radiate off the die like on a heated die, this prevents heat degradation of the material abutting the weld

Ideal welding strength:RF welder is usually run “cold”, this means that once the RF is turned off, the material stops being heated. But remains under pressure, in this fashion, it is possible to both instantly heat, weld and cool the material under compression,more control the weld result in more control over the resulting extrusion, this increasing the weld strength

Superior effect vs sewing: creates airtight and waterproof seams unlike when you sew and are poking hole into the fabric, RF welder also can weld the same area more that once with no damage to the fabric, the specialized dies are made available for intricate welds, seams that are stronger that the material itself for diverse manufacturing job, unfortunately, the sewn fabric is more trended taking apart in tearing force

06: Character

RF Welding bar length, width can be adjusted, fast changeover

European-model square high frequency vibration cavity, more reliable and stable in output

Single or two line both are available, the welding length can make to ordered

Deep material trough,suitable for large size welding in localized seaming position

Customized work tale dimensions, electrode holder dimensions

Laser guide projector: projecting laser lines for quick localized joining seam an the table

High sensitive anti-spark tube to protect the welding bar and welding material

Sealing efficiency from 1kw up to 40 squire centimeters for standard PVC material

Universal usage for PVC,PU, TPU, reinforced technical textiles

The machine routine maintenance is very simple

RF Time, pressure, holding, delaying and dwell time all can be precisely adjusted

Three sets of emergency stop to quick stop working in case of wrong operation

Additional grounding electrode to protect the user against increased HF non-ionizing radiation emitted by the RF welding

Automatic output power control system to increase the operation’s safety

07:Notice

Key considerations in RF tooling include ensuring that uniform thickness is maintained, as well as the removal of any sharp edges or corners, it is also imperative to determine the appropriate level of RF energy that is fed into the seal area using RF Welder, that contains a generator with a high-quality arc suppressor will help regulate the voltage output by stopping the output before damage to the plastic film or die can occur, this will also ensure the temperature does not drop to a level that is insufficient for sealing to take place

Machine Uses

Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder exerts seam sealing of membrane structure in field of following fabrications

Small and large format technical textiles PVC or PU coated

Tensile structures, tents, shade systems, truck covers and side contains

Swimming pool liners and covers, flood dams and water tanks/containers

Airport hangars,portable storage structures

Containment pools, oil booms and ground liners

Advertising sings, banners, and large format billboards

Contact Us

Radio Frequency Dielectric Bar Welding PVC Tarpaulin RF Welder can be used for variety of applications,although the technology has been around for over a half-century, RF Welder is still common in industrial settings and factories,keepleader can fabricate versatile strictures among each individual applications, our tech team is always ready for listening your concerns and work with you

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader