Wire Terminal Bonding Ultrasonic Metal Spot Welder for Al_Cu_Ni_Cu Cable Harness Splicing Soldering Ultrasound Welding Equipment

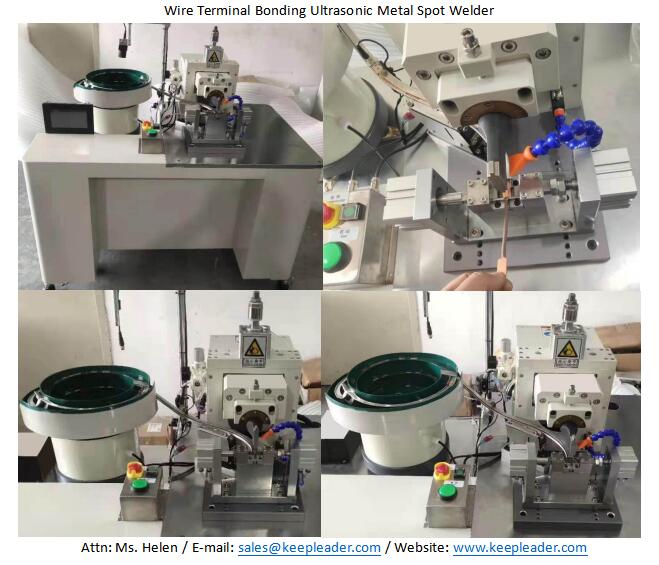

Wire Terminal Bonding Ultrasonic Metal Spot Welder

Wire Terminal Bonding Ultrasonic Metal Spot Welder eliminates twisting, fluxing, and tinning,oxidation, so it is usually faster than soldering, resistance welding and brazing,which is the high frequency vibration between the work piece surface, until the contact surface heating and welding together under controlled pressure, as copper, silver, nickle chromium,aluminum, copper can welding to dot or strip,can be widely applied to silicon chip fuses, quick fuse melts melting, electric wire terminals, lithium ion, nickel metal hydride, nickle cadmium battery pole piece sun as dot, strip welding silver, nickel chromium can welding to dot or strip, which can be widely applied to the silicon chip fuses, quick fuse melts melting, electrical wire terminals, lithium ion, nickel metal hydride, nickel cadmium battery pole piece such as dot, strip welding.

Machine Description

Wire Terminal Bonding Ultrasonic Metal Spot Welder

01: Application

Wire Terminal Bonding Ultrasonic Metal Spot Welder is one of most important joining technology exerted in the manufacture of wire harnesses for the automotive, construction equipment and household appliance industries, among other things, the process is used for joining multiple wires with each other as well as for joining wires with grounding terminals or high-current contact, the wire cross-section size which can be ultrasonically welded ranges up to 30 square centimeters, compared with crimping or resistance welding,ultrasonic welding offers numerous advantages, these include the excellent electrical properties of the joint, extremely low energy consumption and comprehensive process control and corresponding process data management

the following popular welding fields of Wire Terminal Bonding Ultrasonic Metal Spot Welder is just for reference

011:Multi-layer positive and negative electrode welding for dynamic power battery

012:Li-ion battery and polymer battery, copper foil welds nickel sheet, aluminum foil welds aluminum sheet, aluminum foil welds nickle sheet

013:Auto splice welding, formation of electric wire end, welding for electric wires, multiple electric wires bond welding

014:Electric wire and cable welding, terminal, connector, electric parts welding

015:Solar panel battery, flat solar plate, copper and aluminum plate joints

016:Solenoid switch, fuse-less switch, big current joint point welding and dissimilar metal welding

017:Refrigerator and air conditioner copper tube sealing, vacuum parts of copper tube and aluminum tube sealing

02: Parameter

Name | ||

Model | KLM-2620 | Klm-3620 |

Ultrasonic Power | 2600w | 3600w |

Ultrasonic Frequency | 20khz | 20khz |

Power Plug in | 220v,50hz or 110v,60hz | |

Driving Mode | Pneumatic, with air supply 0.3-0.6Mpa | |

Max Welding Area | 20 square centimeter | 30 square centimeter |

Cylinder Bore | 80mm | 100mm |

Cylinder Stroke | 15mm | 15mm |

Working Temperature | 0~40 degree | |

Max welding thickness | 5mm | |

Activation | Adopt the solid crystal type, with functions of automatic frequency tracking With over-current, overheating, mismatch alarm | |

Amplitude adjustment range | 50%~100% | |

Operating humidity | 10%~85% RH | |

Cooling System | Fan cooling | |

Intake Connection | Quick coupling | |

Welding Time | 0.01s~10s | |

Preloading Time | 0.02s~1s | |

Frequency Calculation | 0.00-50000HZ | |

Frequency Tracking | Range ± 20Hz | |

EMI/EMC | Strong anti-interference ability | |

Weight | 45kgs | 50kgs |

Size | Power Box:700*600*400/Head:800*500*500mm | |

03: Salient Features of ultrasonic welder for wire bonding

Oxidation or tin-plated metal is weldable

Welding material does not melt, no fragile metal properties

Short welding time, no need additional flux, gas,solder or filler

Cold solid welder, no sparks, environment protection and safety

Good conductivity and resistivity very low or almost near to zero

Creates permanent, metallurgical bond between dissimilar metals

High quality ultrasonic transducer, strong power and good stability

No melting required,no change to chemistry or metallurgy of material

Ideal for joining highly conductive alloys, reactivity of material does not matter

Creates no inter-metallic components, particulates or corrosion-causing reactions

Works with wide range of nonferrous material, likely copper, aluminum, Nickle, silver, and gold

Not necessary for frequent replacement of amplifier due to step-less adjustment of amplitude

Low energy consumption, high efficiency, no distortion, no pollution, convenient operation, strength welding even stronger that material itself

Compared with other pressure welding, ultrasonic welding requires less pressure and less that 10% deformation, while cold welding require 40% to 90% deformation of work-piece

Ultrasonic welding does not require the pretreatment of the welded surface and the post-treatment of the welded surface as other welding

Ultrasonic welding can minimize the temperature effect of the material, the temperature of the welding zone does not exceed 50% of the absolute melting temperature of the welded metal, so it does not change the structure of metal, so it is very suitable for welding in the electronic components

Not only similar metal, but also dissimilar all can welding together, it can weld metal slice or sleeve to thick metal, usually used for transistor or IC leads welding

04: Character

Easy installation and operation

Microcomputer control, electronic tuning frequency

Power adjustable,operation simple, and run stable and reliable

Over-current protection and soft start can keep the machine safe

High quality ultrasonic transducer, strong power and good stability

Touch screen display keeps the machine visible in operation and regulation

Available with multi optional modes, optional welding quality monitoring system

The ascending and descending speeds can be precisely controlled and adjusted

Accurate positioning of upper and lower positions of the welding mechanism

When the voltage fluctuates, the ultrasonic generator can automatic compensate the output voltage value to ensure stable amplitude output of the welding hone section

The automatic cooling device can reduce the accumulation of heat when the equipment is operated at high speed

Precise energy control method can ensure the stability of each welding and reduce the influence of external factors

Unique ultrasonic welding unit design can maximize the conversion of ultrasonic energy to the welded product

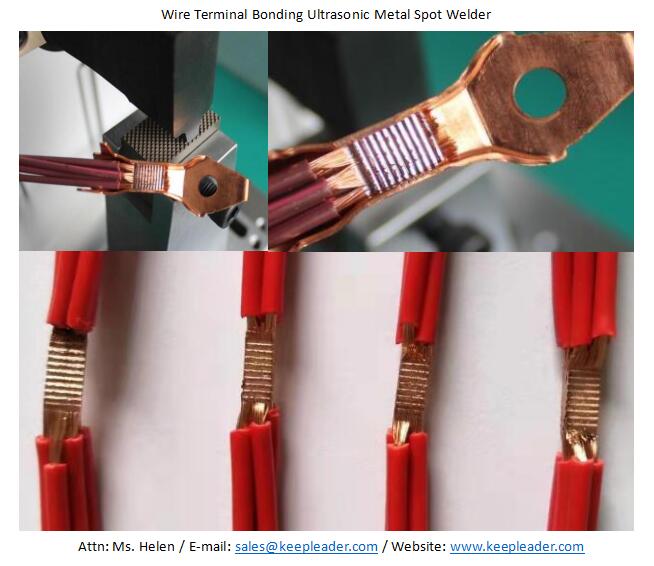

Detailed Images

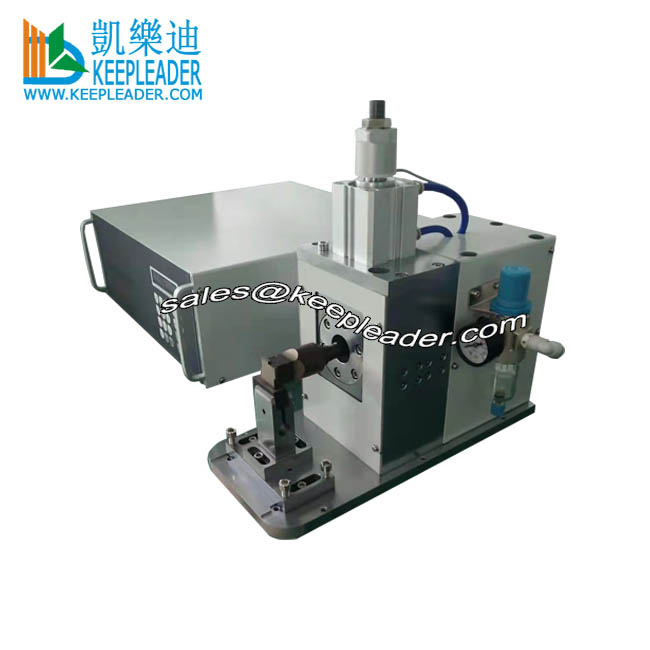

Wire Terminal Bonding Ultrasonic Metal Spot Welder is well-developed and established production method for joining non-ferrous metals, especially in the automobile industry, this reliable and trend-setting technology has been used in the production of wire harnesses for decades, Wire Terminal Bonding Ultrasonic Metal Spot Welder is a cold, friction welding proce4ss, no liquid-melt phase occurs, the parts being joined are rubbed together at their contact surfaces under slight pressure, compared with crimping or resistance welding, this process offers numerous advantages, besides the excellent electrical properties of the joint and the extremely low energy consumption, this method is particularly characterized by comprehensive process control and process data management

Machine Uses

Wire Terminal Bonding Ultrasonic Metal Spot Welder is ideal process of wire welding in precision metal jointing, which is high frequency mechanical friction at the jointing surface of non-ferrous metal without any consumable materials, likely flux, solder, filler, resulting in molecular scale dispersion bonding, works out a surpassed expectation in wire connection, compared with clamping, resistance welding, ultrasonic metal welding machine, welded wire keeps the electric property and mechanical characters, robust bonding, but no fragile, good conductivity and consistent, repeatable, and reliable working performance

Contact Us

We,keepleader persevere in fabricating Wire Terminal Bonding Ultrasonic Metal Spot Welder many years, our main criteria is “we don’t focus on leadership in quantity and sale volume,but, we focus on leadership in quality and service”, to make a essential decision in choosing a correct ultrasonic metal welder is first step in success of wire bonding process, we arranges crucial confirmation prior to production, and promise the last welds are exactly same with previous confirmed specimen,please let us know more your production to find what can do for your individual application

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader