Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine of Top Loading Jet Blasting Parts Hot Water Washing Equipment

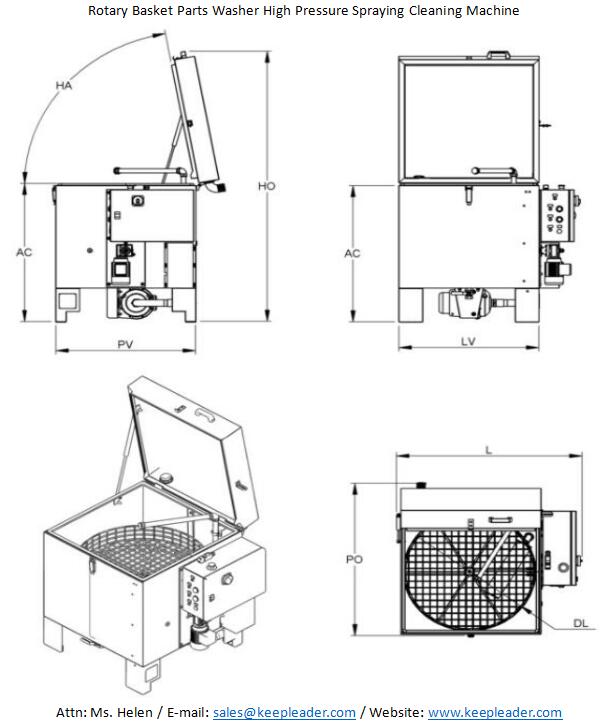

Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine

Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine is carried out by the action of upper, lower and side nozzles, the slow rotation of the platform is ensured by a gear motor with a torque limited, a PLC management enables numberless customization, thanks to a wide range of accessories, particle filtering inter-circulation and status-flow of jetting are also integrated

Machine Description

Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine

01: Application

Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine has been developed to provide fast and efficient cleaning of manufactured components, suitable for parts with simple geometry with batch of small parts loaded on a rotary basket or individual big parts on fixtures, the rotation is driven by a motor and gearbox arrangement in slow speed, during the rotary blasting, the solution formulated water with alkaline from the tank is pumped with the help of high pressure pump to wash chamber of top loading spray washer through inline filter multiple and spray nozzles loaded above, below and to the side of rotary table to attain higher degree of cleaning results, from Rotary table Parts Washer High Pressure Spraying Cleaning Machine chamber it drains back to the tank via a basket filter, spray pressure indicator is provided to monitor the line pressure, low water level indicator and digital temperature indicator controller is provided on the control panel to exert efficient and reliable washing performance

Rotary table Parts Washer High Pressure Spraying Cleaning Machine uses only hot water and biodegradable alkaline detergent products making them good for the environment and good for operator, which is designed for fast and effective space saving and economical high levels of cleanliness can be achieved for low cost and little efforts, the dirty parts placed on the rotating table are cleaned with high pressure chemical liquid, the hot chemical liquid inside the tank is transferred to the nozzle line through the pump, the high-pressure liquid hits the surface of the parts and removes the dirt during operation, the table is rotated at slow speed to ensure that the chemical liquid cleans all surface of the parts in all directional jetting 02: Parameter

Name | Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine | ||

Model | KLE-100RS | KLE-120RS | |

Basket Diameter(mm) | 970mm | 1170mm | |

Loading Height(mm) | 540mm | 700mm | |

Height (Lid open) | 1900 | 2060 | |

Depth (lid open) | 1290 | 1450 | |

Loading Capacity | 200kgs | 300kgs | |

Tank Capacity | 210Lt | 270Lt | |

Flow Rate | 180Lpm | 200Lpm | |

Heater (kw) | 6kw | 8kw | |

Electric (V/Phase/Freq) | 220b/380V/3p/50Hz/60Hz | ||

Control | 24V | 24V | |

Press Time (Min.) | 0~90 minutes | 0~90 minutes | |

Working Temperature | 0~90 degree | 0~90 degree | |

Pump Power | 3.0Hp | 3.0Hp | |

Pressure Pump | 60 Bar | 60 Bar | |

Door System | Pneumatic | Pneumatic | |

Parts Observation | Top Glass Window | Top Glass Window | |

Material | SUS304 | SUS304 | |

Spraying Impingement | Direction from Low, top and side | ||

Function | Rotary spray impingement combined hot water cleaning | ||

Drainage | At the bottom of inner tank | ||

Wall thickness | 2mm | ||

Inner Dimension | 1100*1100*740mm | 1270*1270*900mm | |

Machine Dimension | 1200*2100*1440 | 1370*2270*1600mm | |

Packing Dimension | 1300*2200*1740mm | 1470*2370*1900mm | |

Weight | 300kgs | 380kgs | |

03: Salient Characters

Specified diameter of rotary table and loading height are acceptable

Wash solution temperature and spray pump pressure are adjustable

Filtration range of 150 micron to 5 micron filtration can be provided with online and off-line filtration

Washing,rinsing and drying process can coexist

Stainless steel pumps are suitable to use chemical and high temperature

Steam suction system is available

The oil separator and filtration system are equipped

Maximum liquid level control in tank and filling solenoid valve

Pneumatic cover opening and closing with two-hand safety control unit

Additional basket/fixture in stainless steel

04:Accessories

Rotary table Parts Washer High Pressure Spraying Cleaning Machine are:

Well-designed rotary table washing machine wash chamber with

Mechanical top lid seal, no rubber seal to replace or leak

High pressure vertical/horizontal pumps

High pressure centrifugal blower with electric hot heater for components drying

Sprocket drive system (as opposed to troublesome direct drive or chain drives

Low water shut off protect heat elements for low water conditions

Stainless steel V-jet nozzle, durability and precise 360 degree cleaning coverage

Rotary table component cleaning machine is provided with PLC controlled panel

Gravity filter to keep tanks free of larger debris

Mist collector for exhaust systems

Oil skimmer for effective removal of oil from tank

Washable filtration system for reuse of aqueous solution

A thermostat-controlled electric immersion heater in rotary table

Rinse tank for removing alkalinity from component post spray wash in top load cabinet

05:Operation Schedules

Operating a Rotary table Parts Washer High Pressure Spraying Cleaning Machine is easy to get your parts cleaned without hazardous chemicals, you and your techs deserve a safe working environment that doesn’t sacrifice efficiency or cost-effectiveness, when you are ready to operate your Rotary table Parts Washer, just follow these simple steps and your are done

051: Load those filthy parts on the over-sized rotary table or place them on the sturdy parts tree or hanging parts basket

052: Close and latch the door then set the wash-cycle timer for up to 60 minutes

053: As the rotary table, the parts are blasted from all angles with hot soap and water, the solution is continuously filtered and recycled

054:The powerful force of the jets and the hot detergent combine to remove grease,oil, carbon and other grime in just minutes

055:Unload the clean parts and allow them to flash dry in seconds

06:Buying Guides

Selecting an Rotary table Parts Washer High Pressure Spraying Cleaning Machine that meets all of your cleaning needs can be challenging, parts washers are rarely one-size-fits and it can be difficult to decide what type of machine will bring your company the most value, to make a process easier, when choosing an aqueous cleaning solution there are three main questions you should ask yourself before purchasing

061:How clean is clean enough

Deciding the level of cleanliness you need your Rotary table Parts Washer High Pressure Spraying Cleaning Machine perform will be key factor in choosing a machine, better engineering’s aqueous parts washes can clean across a large spectrum of needs, options span from visible clean to microscopically clean, parts washer that clean to visible standards are perfect for those looking to remove remnants such as dirty. Grease, grime, and other contaminants, therefore, these heavy-duty cleaning systems ideal for manufacturing and industrial rebuild/repair industries. Meanwhile, companies

062: What size and shape are the parts

If the parts that you need to cleaned are small, you may be interested in drum rotary basket/drum washer, or immersion washer with ultrasonic agitation or not, drum and immersion washer clean small items quickly and efficiently, however, large such as totes or dunnage may be best cleaned by conveyor washers, these parts washers clean large items quickly and efficiently and can be customized with robot arm integration

063:How fast does the parts washer need to operate

Your company likely has requirements for how many parts need to be cleaned on a daily, hourly, or weekly basis, because of this, is important to take into consideration how quickly a machine cleans parts when choosing a machine, this will ensure that the machine meets your company’s parts cleaning needs, and cleaning deadlines, companies with high volume needs will likely machine with high levels of automation and robot integration, companies looking to clean a few parts per day may find more valve in an operator run machine, if you are unsure of the type of machine that may best fit your needs,technique team members of keepleader are always ready in assist you in selection with our rich experience

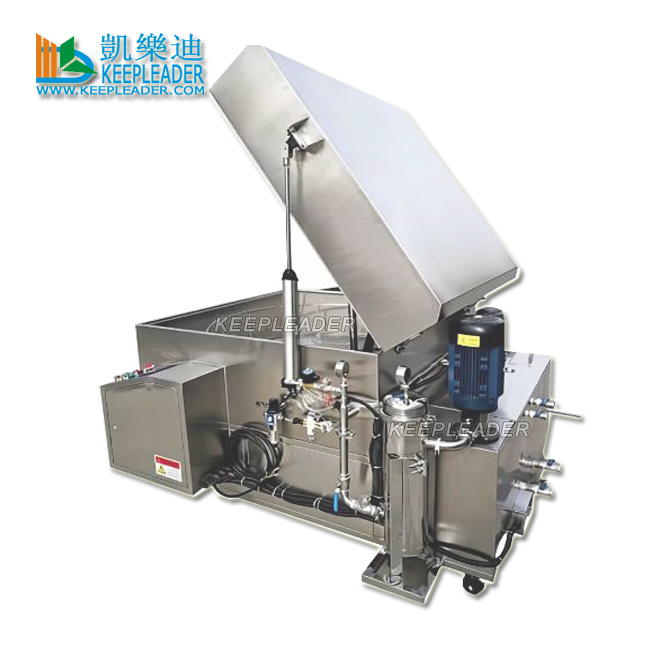

Detailed Images

Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine is designed for medium or large size parts washing, operator place parts onto rotary table or hanging tree, close the top cover and start the automatic cleaning process, a gear motor slowly tunrs the table and the pump sprays the washing liquid over the parts in 360 degree angle direction throughout the spray nozzles, degreasing chemical products mixed with water in low percentage, the temperature and the liquid pressure ensure an appropriate washing of parts, on the switchboard can be set all machine parameters (temperatures, heating starting and washing times) through a colour touchscreen display, and displayed the machine alarms and warnings as well as monitored the washing process status-flow,Rotary table Parts Washer High Pressure Spraying Cleaning Machine can be equipped with a large number of accessories available such as compressed-air blowing, hot air flash drying, tank emptying pump,standard steam extraction and many others you concerns for your individual washing

Machine Uses

Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine is suitable for general cleaning of different components in all process in the same cabinet,which also integrated off-line filtering circulation system to avoid second or cross contamination and save the water consumption, is ideal washing solution of wide variety of components, intermediate or final cleaning in the automatic parts washer, general engineering washing by rotary table,thanks our rich experienced technical teams to impel us to be a leading supplier of cleaning solution in aerospace, manufacturing, railway degreasing, hydraulic industry of cylinder washing, metal pressing industry of pressed component washing, metal casting industry, printing industry and crankshaft washing and other middle or large size parts washing

Illustration

Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine is exerted aqueous washing with alkaline solvent immersed into hot water, which is jetting blast from 360 degree angle V-jet nozzles under high pressure, in addition, off-line filtering circulation system is integrated into cleaning cabinet to achieve a whole cleaning process, customized diameter of rotary table, loading height and other specified configuration are all acceptable

Contact Us

Rotary Basket Parts Washer High Pressure Spraying Cleaning Machine is ideal solution of aqueous cleaning for medium or large size parts, which also can combine rotary drum immersed into immersion tank with ultrasonic agitation for small, medium and large size parts cleaning, all of our rotary table washers are considered in line or off line filtering system to reduce water consumption, avoid cross-contamination, we know that the various practical cleaning process cannot be satisfied in an invariable solution with fixed structure and configuration, that’s why we always listen to clients’ existing procedures, unsatisfied aspect in cleaning effect, expected process and additional concerns in improving our achievement

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader