Degreasing Bath Solvent Vapor Degreaser Machine of Small Vaporized Tank Glass Cleaners Industrial Ultrasonic Cleaning Equipment

Degreasing Bath Solvent Vapor Degreaser Machine

Decreasing Bath Solvent Vapor Degreaser Machine adopts boiling solvent to form vaporized zone and top integrated condensing blanket for fast precision cleaning and removal of true oils from parts, vapor degreaser applies the principle of distillation and condensation to achieve high-quality cleaning and quick drying, our vapor degreaser comes in a variety of configurations depending on customer application, keepleader can size a vapor degreaser to fit not only your parts, but also your cycle time and production requirements, with today’s solvent it is essential to size the vapor degreaser properly to ensure maximum solvent recapture through distillation circle chilling coils

Machine Description

Decreasing Bath Solvent Vapor Degreaser Machine

01: Application

Decreasing Bath Solvent Vapor Degreaser Machine is employed for metal, glass parts prior to inspection and assembly, or in preparation for subsequent processing or finishing operations such as rust-proofing, panting, electroplating anodizing, and galvanizing,other material such as glass, leather, ceramic, and plastics can also be cleaned by this method, essentially, Decreasing Bath Solvent Vapor Degreaser Machine comprises suspending work in the vapors of trichloroethylene, or another chlorinated solvent, causing the the hot vapor to condense on the surfaces, the liquid condensate washes the parts from of contaminates, the parts is removed from the degreaser, clean, dry and ready for the next operation, the vapor stage may be combined with immersion in boiling or warm solvent with ultrasonic agitation, or spraying with warm solvent, as may be required by the shape, size, and type of parts, and nature of the soil to be removed, thus keepleader may have different cycles or occasional variations for special conditions, the following fields are utmost considered in exerting cleanliness of pre or post production

011: Precision cleaning medical device parts where critical that chemical residue is left on parts

012: Manufacturing processes requiring precision cleaning of true oils and particulates and quick drying

013: Semiconductor printed circuit board cleaning and flux removal

014: Aerospace parts cleaning for components required to conform to specification

015: Optical glass parts cleaning prior to installation

02: Parameter

Name | |

Model | KLE-1024R |

Ultrasonic power | 1200w |

Ultrasonic Frequency | 40khz |

Heating Power | 2kw |

Air compressor | 2HP |

Filter pump | 3.7kw |

Power Supply | 220v,60hz or 380v,50hz, single phase |

Auxiliary | Tank lid, cleaning basket |

Cleaning Process | Ultrasonic immerse scrubbing +Vapor cleaning + Condensing Dry |

Solvent process | Boiling+ vaporized + Condensing + Oil water separator + Filtering Pump |

Material | Stainless steel |

Heating Chamber | 300*380*380mm |

Vapor Zone | 300*380*380mm |

Overall size | 1.096*0.606*0.96m |

Packaging Size | 1.27*0.71*1.16m=1.046CBM |

Net Weight | 150kgs |

Gross Weight | 185kgs |

03: Salient Feature

031:Thoroughly removes grease, oil, chips, and most other contaminants from metal parts of any shape,size, usually in a minute or less

032: Leaves parts clean, warm, dry, and ready for inspection, assembly, further fabrication, or finishing of any type

033: Minimizes rejects because vapor reaches and removes contaminants from deep draws,holes, and places which are most inaccessible

034: Reduces risk of damage to delicate parts

035: Can be used along, or as part of a process flow line

036: Utilizes compact equipment that fits into small space

037: Consumes only small quantities of solvent, contaminated solvent is recovered economically for re-use

038: Uses the absolutely pure vapors of a nonflammable solvent as a cleaning medium

039: Simplifies cleaning procedure, is easy to operate

0310: Saves time and cost in its own operation, and in the subsequent handling and finishing of parts

0311: Unique feature of the process, no matter which combination of treatments may be used, is that work leaves the machine through the vapor area, and is washed with pure liquid solvent which has condensed on all surface, the parts are thus heated to the vapor temperature, and, on passing above the vapor level, are quickly dried by evaporation before removal from Decreasing Bath Solvent Vapor Degreaser Machine

04: Operation procedures

Degreasing Bath Solvent Vapor Degreaser Machine takes simplicity in cleaning procedures to achieve completion resulting precision cleaning, rinsing and drying in a compact tank, following chart supports a reference in guidance

Step4.1: Boiling the solvent: First, add the solvent to the vapor degreaser and set the temperature for boiling it, different solvents boil at different temperatures

Step4.2: Activation the vapor degreaser: Turning on the vapor degreaser will activate the cooling coils as well as the heating elements that will boil the solvent, the cooling coils above the heating element ensure that a vaporized solvent remains trapped in a vapor zone inside the vapor degreaser, instead of rising and escaping

Step4.3: Introducing the parts to be cleaned: The parts to be cleaned are added to a metal basket that is lowed in the vapor zone inside the vapor degreaser, either by hand or with automation, the solvent vapor will condense on the parts,eating away at grease and dirt

Step4.4: Removing the parts: As the basket is lifted slowly out of the vapor zone, the cooling coils cause the vaporized solvent to condense further, the solvent then drips off the parts, carrying dissolved grease and solids with it, the dripping solvent is collected at the bottom of vapor degrease for re-use

Step4.5: Ultrasonic degreasing:Ultrasonic agitation integrates at the beneath of boiling sump for our Degreasing Bath Solvent Vapor Degreaser Machine, if any grease or solids remain on the parts after vapor degreasing, ultrasonic degreasing may be required, cleaning parts submerged in boiling sump exerting ultrasonic micro-scrubbing is helpful in dislodge any stubborn solids

05: Frequency asked question

Desiccants are used to absorb the water found in humid condition to reduce or eliminate condensation, it can also be added directly to liquid to absorb the water content from the fluid, the desiccant used in Decreasing Bath Solvent Vapor Degreaser Machine is 3 Angstrom molecular sieve, small pellets of zeolite clay, like all desiccants, the zeolite clay absorbs water from the solvent, and maybe reused by baking it dry, desiccants are most often used in Decreasing Bath Solvent Vapor Degreaser Machine if the solvent contains an an alcohol, this is often the case with solvent used for de-fluxing process on soldered boards and leads, water found in the separator extracts the alcohol from the solvent and in turn the water and alcohol are absorbed by the zeolite clay,if a Decreasing Bath Solvent Vapor Degreaser Machine is operated in a very humid environment, a desiccant may be needed to effectively remove the water from the solvent

06:Operation checks

The following procedures necessitate checking when setting up up an new Degreasing Bath Solvent Vapor Degreaser Machine

061: Check for solvent leaks: leaks can be in the solvent containment systems-sump, return troughs, condensing coils, and connecting pipes, almost anywhere the solvent travels such as lines, pumps (including system seals,gaskets),and the water-solvent separator, anywhere there are welds or canister bolts (such as the water separator), the potential for leaking exists, besides the solvent systems, the refrigeration system must be checked from compressor, through the discharge line, and back to the compressor via the suction line

062: Verify the cooling system is functioning properly: Beside leaks, the refrigeration system necessitates verification that not only it is cooling, but also it can operate adequately to handle the heat load generated during condensation of the hot vapors

063: Check set point temperature of the heating system: The heating system should be checked that it is operational and can hold the set point temperatures, this can be conducted by comparing it to readings from separate thermometer, safety temperature overload should also be verified

064: Check ultrasonic agitation and frequency: Ultrasonic transducers should be checked for the correct frequencies, 28khz and 40khz are popular option, which depends on your material of cleaning components and confirmed prior to fabrication of machine your ordered, the 28khz is generally used for large parts cleaning while the 40khz is seen in more precision cleaning application such as very small or highly complex geometrically shaped components, some degreasing Bath Solvent Vapor Degreaser Machines may have multiple transducers, these either can be outside and attached to the sump (usually the wall but can be on the bottom plate) or can be inside the sump (usually looks like a round bar extending into the fill area of the sump)

065: Test electronics controls: All electronic controls should be verified that they can be properly activated and deactivated

In addition, if your degreasing Bath Solvent Vapor Degreaser Machine has required features from manufacturer in spraying wand and hoist, following checks also necessitate consideration

066: Test wand operation: wand operation should be checked for activation and cut-off by whatever mechanism it uses, most of the time, it is power-activated by a food switch pedal

067: Test movement of robotics: If so equipped, any movement robotic should be checked that they follow the programming guide in time, distance, direction, correct stopping, and smoothness of operation

07: Characters

071: Quality material, 304L stainless steel with 316L stainless steel welded components for long term reliability

072: Vapor condensing collar to minimize evaporation and chemical usage

073: Air-tight lid to trap the vapor and reduce the emission in idle status

074: Removal panels on the front for readily maintenance access

075: 100% standard freeboard,120% or greater option

076: Sloped tank bottom that provide ease of maintenance when cleaning

077: 360 degree peripheral cooling coils surround the internal tank walls with stainless steel condensate troughs

078: Stainless steel external water separator with removable lid

079: Tank provided with thermal insulation covered by stainless steel panels for corrosion resistance and first class appearance

08: Acid acceptance for Degreasing Bath Solvent Vapor Degreaser Machine

Decreasing Bath Solvent Vapor Degreaser Machine is very efficient at removing soils from a variety of surface, and maintaining its efficient operation is relatively easy, one concern that arises with the use of Decreasing Bath Solvent Vapor Degreaser Machine is the determination of when the solvent used in the degreaser is spent, which can mean that either the solvent is saturated with soil, or the solvent stabilizers has begun to acidify” or “go acid”

081:Soil saturated level: There are a variety of ways to determine the soil saturation level, including an increase in boiling temperature, or a shift in specific gravity when can show that the system has reached its soil loading capacity, soil loading capacity of 25% oil by volume is reached when solvent boiling temperature climb,increasing rate depends on the specific solvent being uses, although this is useful measure of soil loading, the test does not show the integrity of the solvent, a simple way to determine this is the acid acceptance test

082: Determination of acidity: As a halogenated solvent is used in Decreasing Bath Solvent Vapor Degreaser Machine, the solvents can slowly break down and form acidic species when exposed to catalytic contaminants such as magnesium, zinc, aluminum, and other fine metal particles, in addition to these contaminants, what that is introduced into the Decreasing Bath Solvent Vapor Degreaser Machine as condensation can accelerate the decomposition and simultaneously remove the stabilizes that are introduced into the degreaing solvent to prevent the solvent breakdown, these acidic material can etch and corrode metals in the Decreasing Bath Solvent Vapor Degreaser Machine and the parts to be cleaned, the acid number test can be run to determine if the solvent is has reached the end of the useful life due to acid formation. Several test method are available for measuring this, including acid acceptance of chlorinated solvent and standard test method for ph of water extractions of halogenated organic solvent an their admixtures

09: Solvent selection

Not all solvent are created equal, modern chemistry has overcome many of the environmental and safety challenges of older cleaning solvents like hydrochlorofluorocarbons (HCFCs), trichloroethylene (TCE) and n-propyl bromide (nPB),the chemical company never cease innovation on reliable solvent of environmental-friend and operation-safe considered, their engineered fluids were specifically invented to combine strong cleaning performance with sustainability (zero ozone depletion potential and low global warming potential) and a high margin of worker safety (low toxicity,non-flammable and no odors)

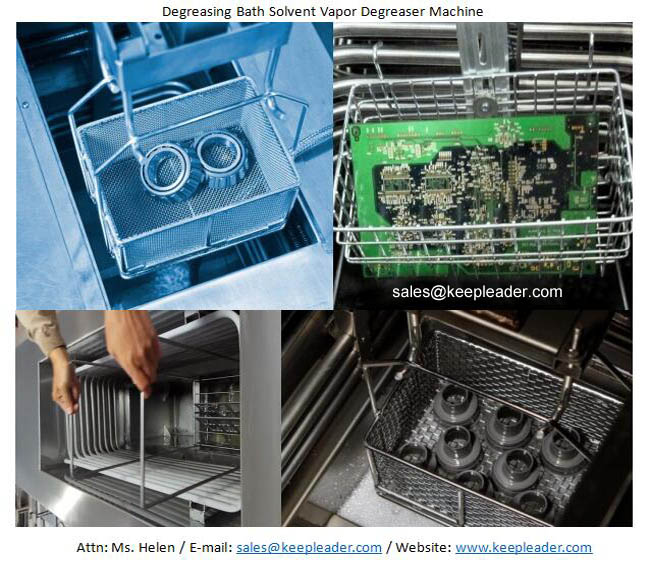

Detailed Images

Decreasing Bath Solvent Vapor Degreaser Machine supports your clean-room process validation with utmost features in #1: dependable and consistent cleaning #2: environmental-friendly process #3:consistent cleaning with little monitoring #4: scalable and repeatable for simplicity #5: easily documented for streamlined record-keeping #6: easy for qualified,trained personnel #7: low maintenance for easy use #8: more controlled work setting #9: compact structure and robust construction

Machine Uses

Degreasing Bath Solvent Vapor Degreaser Machine uses a specially formulated cleaning fluid, parts are immersed in a continuously filtered and distilled fluid, also combined with ultrasonic ultrasonic agitation, and contaminants dissolve off their surfaces, parts then undergo a brief vapor rinse and drying process, where the fluid condenses and drips back into the vapor degreasing sump to be reused and are removed dry

Degreasing Bath Solvent Vapor Degreaser Machine is often highly effective at #1: cleaning mechanical and electronic parts with complex geometries #2: cleaning with zero residue #3:cleaning high volumes of parts rapidly #4:cleaning sensitive parts that need a low-temperature drying process

Contact Us

Decreasing Bath Solvent Vapor Degreaser Machine undergoes rigorous quality control to ensure the prominent performance, moreover, creates configuration with environmentally friendly structure and materials, the technique’s teams are responsible for you and our planet, that’s why our vapor degreasers are fabricated with harmful chemicals, whatever vapor degreaser you decide on, your business will be able to depend on it with no issues,it utilizes the ultrasonic capabilities you’d expect, with modern emissions control and safety precautions, most importantly, this vapor degreaser is thoroughly designed to not only operate efficiently, but also effectively handle a wide range of degreasing solvents that are available, get in touch with us now, we’d love the opportunity to discuss your options for Decreasing Bath Solvent Vapor Degreaser Machine with you, we are a leading company that specializes in more that just ordinary ultrasonic cleaners, we also carry a line of large automatic production in cleaning, our professionals are passionate about how our vapor degreasers make a difference in every industries, so we’re ready to guide you in making the right financial investment for your company, your initiation is our direction in continuous efforts

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader