PVC Name Badge Pocket Holder Making High Frequency Welding Machine of Vinyl Clear ID Card_Tag Pouches Holders Auto HF/RF Sealing

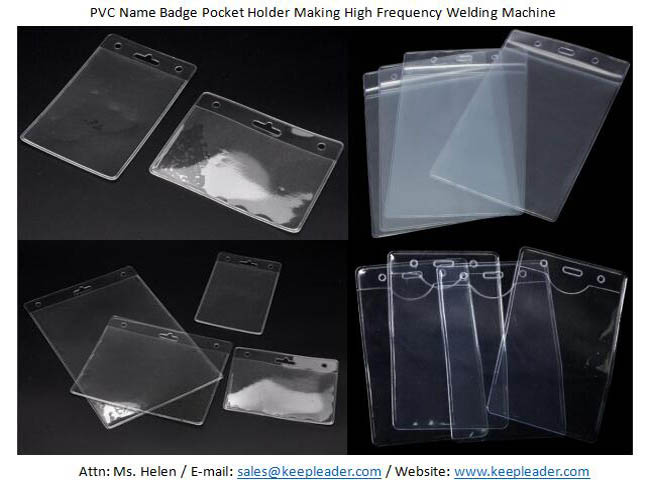

PVC Name Badge Pocket Holder Making High Frequency Welding Machine

PVC Name Badge Pocket Holder Making High Frequency Welding Machine is 8kw H.F welder integrated with flattening device, punching unit, automatic transmission feeding and collecting system in form of automatic production line, its productive ranges cover versatile shapes and sizes of PVC,PET,PP bags,case,name card keeper, ID card holder, Clear plastic purse,tote bag, blood bag,urine bag,infusion bag, book cover, inner page,PVC badge holder,plastic pocket,wallet, punch and etc soft bag

Machine Description

PVC Name Badge Pocket Holder Making High Frequency Welding Machine

01: Application

PVC Name Badge Pocket Holder Making High Frequency Welding Machine is H.F welder integrated automatic transmission of material in roll, auto flattening/leveling device, auto punching sect to built hanging holes and automatic collecting system after completing multiples badge holders in roll but ready for stripping, the produced badge holder has versatile classifications in business card holder, name card sleeve, PVC ID card holder,PVC pouch, plastic pocket, band card cover, identification Card Holder, multiple-layers pocket badge holder is built in laminated 2~5 layers, the machine supports many rolls feeding in automatic transmission, if there is rigid material layer, the auto flattening/leveling device can quickly connect into whole production, but, only flexible plastic layers is used in building badge holders, the production also can leave the flattening device in ideal status, this flexible arrangement satisfies versatile production, thanks to years of practical construction and endless efforts of keepleader’s technical team, this PVC Name Badge Pocket Holder Making High Frequency Welding Machine is prominent considered by clients around the wold to enhance their production in making card holders at affordable cost

02:Parameter

PVC Name Badge Pocket Holder Making High Frequency Welding Machine | |

Model | KLR-8KW-CZY |

H.F Power | 8000w |

Power Supply | 380v,50hz three phase or 220v/60hz three phase |

Frequency | 27.12Mhz |

Input Power | 15KVA |

Rectifier | Silicon Diode |

Oscillation Tube | 7T69RB |

Maximum Pressure | 1000kgs |

Pressure Mode | Hydraulic |

Flattening/leveling | Oil heat |

Anti-spark device | Sensitive spark suppressing system:NL-5557 |

Electrode Distance | 200mm |

Active Electrodes | 100mm |

Upper Electrode | 500*700mm |

Bottom Electrode | 600*800mm |

Temperature range | 30~200 degree adjustable |

Welding Time | 0.01~9.99s adjustable |

Productivity | 3~6 seconds per circle |

Net Weight | 1380kgs |

Gross Weight | 1880kgs |

Packaging Volume | 12CBM |

03: Salient Characters

Programmable Logic Control with touch scree is visual in setting and operation

Easy and simple access channel in resetting, maintenance, and trouble-shooting

All functions are clearly labeled on the display panel,which is convenient to access

Modular component design minimizes maintenance requirements

Automatic material roll feeding in ranges of PVC,EVA,PU,PETG,APET,GAG or PP

Adopt High Q oscillation tube for stable and reliable output

Pneumatic pressing system,max pressure can up to 1000kgs

Heated Electrode with horn holding plate for good plastic welding result

H. F generator at a stabilized frequency of 27.12Mhz with tolerance 0.6%

With 5557 anti-spark system to protect mold and welding material in case of over-current

Transmission system uses wear resistant resin material to reduce its consumption

Transmission poles rolls, all are coated with suede adhesive cloth to avoid scratching

Auto feeding material roll has adjustable speed, its width and apart distance is rectified

Stepped motor driving transmission system to exert roll feeding

Flattening/leveling device is installed stands next to material roll stand for multiple layers

Completed bags in roll automatically collected and pull out of transmission belt

Taiwan, Taiwan AIRTAC pneumatic components, Japan's "OMRON" relays, micro switch.

Accurate counterpoint of auto transmission system, punching mold and welding system

Great Shielding structure, all the parameters has passed the inspection of state department

Detailed Images

PVC Name Badge Pocket Holder Making High Frequency Welding Machine has compact structure, robust construction, and customized configurations, Interchangeable molds is supportive in making versatile pvc badge holders, flattening device and punching unit assist on processing of rigid material layers with hanging holes in auto production line, the controlling system installed touch screen which is visual and convenient in reading, displaying, operating, maintaining and malfunction-shooting

Machine Uses

PVC Name Badge Pocket Holder Making High Frequency Welding Machine is suitable for making plastic pocket, punch, case, bag, sleeve, book cover, inner page, photo album, ID card and badge holder of Double or multiple-layers laminated,the hanging hold is also can applied, if rigid material laminates the flattening/leveling device can exert flattening process prior to contour sealing

Contact Us

PVC Name Badge Pocket Holder Making High Frequency Welding Machine clarifies H.F welder combined Flattening device, punching unit and automatic transmission system in making plastic sleeve,bag,case,pocket, punch,keeper, holder, because of their individual processes in laminated layers, material property, size, shape, and extended procedures, likely punching, printing, automatic collection, keepleader’s technical staffs continue to its rectify its detailed construction to apply reliable and consistent production, if you still cannot find your concerns but which are vital for your output or quality, don’t hesitate to consult them with our experimental engineers for technique audit prior to offer, we believe that versatile views in initiation of your production always avoid unexpected loss and improve efficiency

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader