Threaded Inserts Installation Ultrasonic Plastic Welders for Thermoplastic Staking_Embedding_Sealing Ultrasound Welding Machine

Threaded Inserts Installation Ultrasonic Plastic Welders

Threaded Inserts Installation Ultrasonic Plastic Welders converts electrical power into mechanical vibrations, the downward force is typically provided by a pneumatic cylinder, while an ultrasonic horn delivers mechanical energy to the metal-plastic surface to apply inserts retention into the hole at plastic bosses, the horns are made from various metals, including titanium alloys, stainless steel and aluminum alloys, ultrasonic horns directly contact the metal inserts, an the horn vibrates the mechanical energy is transferred to the plastic surrounding the insert, creating frictional heat to melt the plastic, Threaded Inserts Installation Ultrasonic Plastic Welders offer advantages, first, it is fast, ultrasonic installtion is generally fast inserts less than 6.4mm OD, (the process takes longer as inserts size increases.) second, the Threaded Inserts Installation Ultrasonic Plastic Welders can often be repurposed as an ultrasonic welder, directly jointing two plastic parts, and third, it is flexible, horn sizes and shapes can be easily changed to accommodate different insert sizes, as much as 75 percent of an insert’s performance is a direct result of how well it was installed, as a result, all the factors that affect installation, must be carefully controlled to maximize performance with so many different combination of insert types, plastic types, and performance requirements, engineers are well-advised to consult with experts on inert installation, the right choice of insert and installation method can be the difference between part failure in the field and part integrity for the intended life of the assembly

Machine Description

Threaded Inserts Installation Ultrasonic Plastic Welders

01: Application

Threaded Inserts Installation Ultrasonic Plastic Welders are typically used for thermoplastic inserts installation, the process deploys high frequency ultrasonic acoustic vibration in a localized area to press fit inserts into part geometries, creating a solid-state weld, this process of inserts installation used for medical device, automotive parts, aerospace components, and electronic assemblies, appliance, ultrasonic generator transfer electric current 50hz,60hz to high frequency current alternation 15khz,20khz, the ultrasonic transducer convert sonic wave to mechanical vibration via expand and contract of piezoelectric ceramic, the pneumatic actuator drives the vibrating horn hold press the inserts into the opened hold, the vibration generate heat to melt the bosses wall fill into the retention undercut, knurling serration, barbs to deploy pull-out and torsion resistance,the horn is made of titanium, which takes vibrating press on the holding surface of inserts to avoid abrasive wear, threaded Inserts Installation Ultrasonic Plastic Welders is the fastest, most repeatable and economical assembly method available to the industry today, with ultrasonic vibrating displacement, most thermoplastics can be assembled without heat, mechanical fasteners, or hazardous consumables such as adhesives or solvent, it can join parts, small or large, simply or complex with low reject rates that any other method,using ultrasonic, labor, both as a skill factor, and as a time factor is significantly reduced, and since the equipment can readily be automated, any non-technical operator can be trained in minutes to produce high volume, high integrity inserts assemblies,in plastic fabrication, insert assembling is prominent considered in many industry fields, such as aerospace,automotive, defense, electronics, general manufacturing, medical,recreational equipment manufacturing, transportation

02: Parameter

Name | |||

Model | KLC-2615 | KLC-3215 | KLC-4215 |

Ultrasonic Power | 2600w | 3200w | 4200w |

Max Input Power | 1.2kw | 1.9kw | 2.3kw |

Phase Voltage | 110v,60hz or 220v,50hz | ||

Ultrasonic Frequency | 15khz/20khz | 15khz/20khz | 15khz/20khz |

Max Deployed Size | 200mm | 220mm | 250mm |

Excursion | 70mm | ||

Vibrating System | Auto-Stimulating | ||

Oscillation Time | 0.1~99s | ||

Air Pressure | 2~7 bar | ||

Air Compressor | 1~2HP | ||

Net Weight | 120kg | 120kgs | 238kgs |

03:Salient Features

Threaded Inserts Installation Ultrasonic Plastic Welders has utmost advantages include

Ultrasonic inset installation is faster, this typically leads to shorter cycle time

The horn can be easily changed to accommodate different sized and shaped inserts

Ultrasonic installation machine can also be used for plastic to plastic welding

Ultrasonic installation can quickly deploy inserting without preheating

Compact structure and table top type can save floor space

04: Character

Intuitive and easy to use operation panel

Low trigger force for delicate and miniaturized parts

Closed loop actuation system can be instantaneously

Best repeatability from the advanced actuation system

New quick-change process provides a faster set-p time

Auto-sweeping frequency to match the resonating vibration

The straight line guide bearing, the precision matching device

Pneumatic cylinder driven the actuator to apply controlled pressure

New round or square column design improves rigidity and alignment retention

The horizontal mounting flange of horn is convenient to adjust the pressing balance

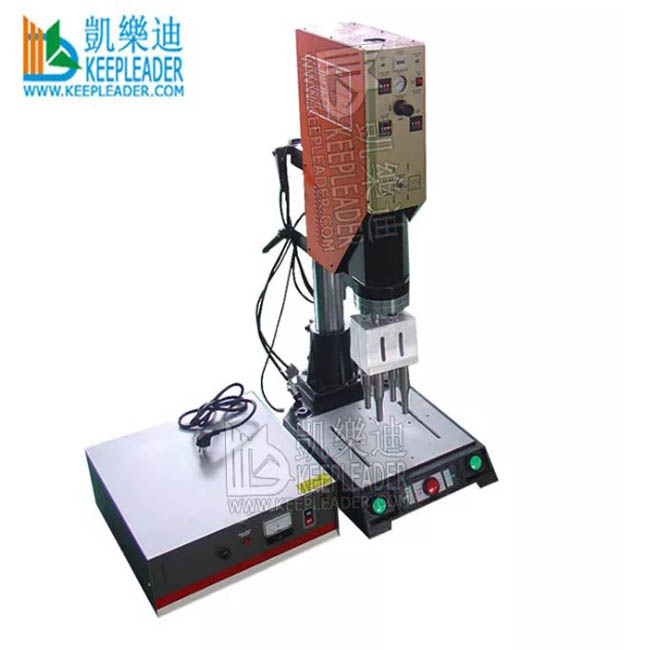

Detailed Images

Threaded Inserts Installation Ultrasonic Plastic Welders deploy process that was originally developed for joining thermoplastic parts, within a very short time, the plastic material is plasticized by boundary-layer friction and vibration absorption of the parts to be joined, this is followed by the joining process, the necessary energy is generated as alternating voltage in the ultrasonic generator, converted into mechanical vibration of 15khz or 20khz, and then introduced with a ultrasonic horn, with the embedding of threaded inserts of metallic M2~M6 in ther thermoplastic material, the melted material is force into recessed areas and undercuts

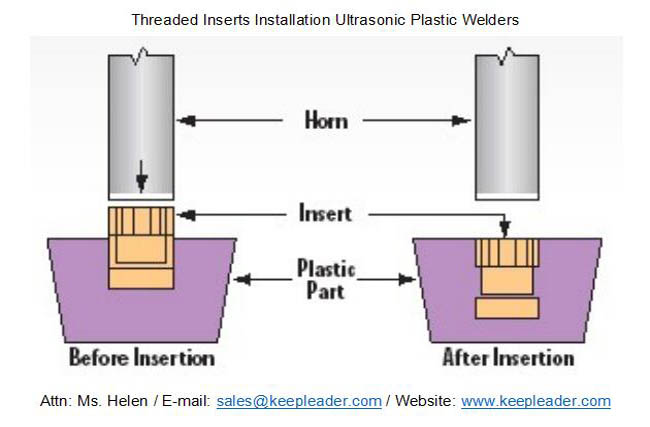

Functional Illustration

In threaded Inserts Installation Ultrasonic Plastic Welders converts, a metal insert is place in a cored or drilled hole which is slightly small that the insert, this hole provides a certain degree of interference and also serves go guide the insert into place, the vibrating, ultrasonic horn contacts the inserts, and the ultrasonic vibrations travel through the insert to the interface of metal and plastic, heat generated by the insert vibrating against the plastic causes the plastic to melt, and as the horn advances, the insert is embedded into the component, the molten plastic flows into the serrations, flute or undercuts of the insert, and when the vibrations terminate, the plastic re-solidifies and the insert is securely encapsulated in place, in ultrasonic insertion a slow horn approach, allowing the horn to develop a homogeneous melt phase, is preferable to pressing the inset, ultrasonic insertion provides the high performance strength values of a molded-in insert while retaining all of the advantages of post-molded installation, inserts can be ultrasonically installed in most thermoplastic

Machine Uses

Threaded Inserts Installation Ultrasonic Plastic Welders have prominent advantages over other methods include rapid installation, minimal residual stresses in the component following insertion, elimination of potential mould damage,reduced mould fabrication costs and increased productivity as a result of reduced mould cycle times, in some applications, multiple inserts can be embedded simultaneously with special horns increasing productivity and further reducing assembly and manufacturing costs,threaded Inserts Installation Ultrasonic Plastic Welders are not restricted to standard type of threaded inserts, inserts that can be installed ultrasonically include a variety of bushings, terminals,ferrules,hubs,pivots, retainers, feed-through fittings,fasteners, hinge plates,binding posts,handle-locating pins and decorative attachments, typically, the plastic component is fixture and the insert is driven in place by the horn, however, in some cases, the part configuration might prohibit insert contact by the horn, and the horn is made to contact the plastic component instead of the insert

Contact Us

Threaded Inserts Installation Ultrasonic Plastic Welders have many benefits that come with ultrasonic installing inserts, one of them is versatility, this installation machine can be changed to accommodate different sized and shaped inserts, another perk is Threaded Inserts Installation Ultrasonic Plastic Welders also can be used for plastic-to-plastic welding and other processes,so, just tell us your intended process in spot welding, hermetic sealing, stitching, inserting, embedding, staking, swaging and others, our engineer will works out customized welding horn in compliance with your application

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader