Circulating Filtration Cleaning Bath Ultrasonic Cleaner of Auto Parts_Engine Block_Supersonic Degreasing Machine with Oil Filter

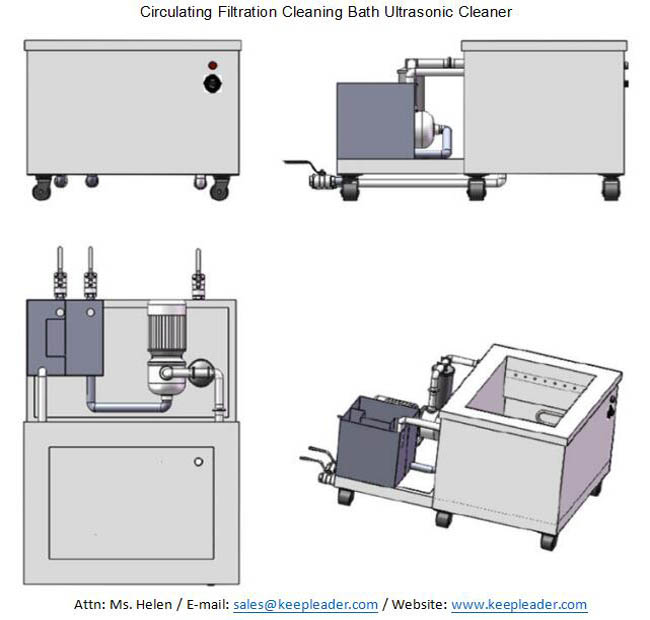

Circulating Filtration Cleaning Bath Ultrasonic Cleaner

Circulating Filtration Cleaning Bath Ultrasonic Cleaner works by creating a large number of microscopical bubbles in the cleaning tank, a phenomena called cavitation, the bubbles are a vacuum created by high pressure pressure waves moving through the water, every ultrasonic cycle bubbles are formed and collapsed, releasing energy as heat and minuscule strong water jets, these effects combined thoroughly clean all surfaces down to a microscopic level, in addition, circulating filtration reservoir is integrated into the fluid flow procedures,which can efficiently improve cleanness via removing floated oil and settled sludge in a closed processing circle

Machine Description

Circulating Filtration Cleaning Bath Ultrasonic Cleaner

01: Application

Circulating Filtration Cleaning Bath Ultrasonic Cleaner uses of high frequency sound wave to remove a variety of contamination adhering to parts like metal, plastic, glass, rubber and ceramics,contaminants can include dust, dirty, oil, rust, solder flux, grease, bake-on carton, lime scale, polishing compounds, mold release agent, fungus, bacteria and so on, this ultrasonic cleaner constructs filtering circulation system, which is considered for saving water consumption, and removing floated oil and dislodged residues to avoid cross contamination, Circulating Filtration Cleaning Bath Ultrasonic Cleaner can vary in cleaning application of automotive, printing, marine, medical, pharmaceutical, electroplating, disk drive components, engineering and chemical fiber industries

02: Parameter

Name | |

Model | KLE-1058R |

Ultrasonic Power Output | 3kw |

Power Supply | Phase Voltage:110v,60hz or 220v,50hz |

Ultrasonic Frequency | 40Khz or 28khz |

Heating Power | 4kw |

Cleaning size inside | 800*650*650mm |

Filter reservoir Size Inside | 400*328*328 |

Pump Power | 0.3kw |

Temperature Range | 35~95 degree |

Temperature Controller | Digital Control |

Timer | 0~99 minutes |

Power intensity | Adjustable |

Ultrasonic Generator | Integrated into cabinet |

Filtering System | Filter, Separated reservoir,filtering reservoir and cartridge |

Construction | Stainless steel enclosure 304, and tank 316 |

Weight | 360kgs |

Measure | 1100*1300*1100 |

03: Working Principle

Circulating Filtration Cleaning Bath Ultrasonic Cleaner consists ultrasonic generator, soap tank, ultrasonic vibrating spectrum, filtering circulation system, the built-in ultrasound generating transducers produce ultrasonic waves in the fluid by changing size in concert with an electrical signal oscillating at ultrasonic frequency, this creates compression wave in the liquid of the tank which tear the liquid apart, leaving behind many millions of microscopic voids or partial vacuum bubbles, this bubbles collapse with enormous energy, however, they are so small that they do no more that clean and remove surface dirty and contamination adhering to parts like metal, glass, rubber and ceramics, this action also penetrates blind holes, cracks and recesses, the higher the frequency, the small the nodes between the cavitation points, which allows for cleaning of more intricate detail, the intention is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surface, water or solvents can be used, depending on the type of contamination and work-pieces, built-in filtering circulation can timely remove stripped-off particles in floating and sludge settled at the bottom of cleaning tank, which is auxiliary device to enhance cleaning effectiveness and decreasing liquid consumption

04: Functional Variation

Variables in Circulating Filtration Cleaning Bath Ultrasonic Cleaner include

Temperature of fluid

Gas contact of the fluid

Shape of pressure pulse

Flow and filtering of the fluid

Fluid contaminants such as water

Cavitation density changes with time

Cavitation density changes with position in tank

Geometry of system and associated fixture

Nature of the cleaning fluid if different from the transducer media

Surface in the transducer media that must transmit the pressure waves

Nature of ultrasonic cycle train(quiet time, degas time cycles per train)

Energy of cavitation implosion (temperature, pulse height of ultrasonic wave

Amplitude and frequency of pressure wave (energy density, standing wave pattern)

05: Salient Character

All stainless steel construction

Low water level sensor prevent dry run

Slopping tank base, effective draining out sludge

Dedicated connections for closed loop circulation

Operating panel in ergonomic and comfortable angle

Simple operation, and complete safety protection function

Adjustable ultrasonic power density, adjustable cleaning time

Consistent cleaning small apertures, blind holes, and crevices

Advanced diagnostic,performance monitoring and service capabilities

Aluminum casting heating plates take temperature raised to rated scale

Sweep frequency generator provides effective cavitation with no standing waves

Advanced driven circuit of ultrasonic generator to perform even and strong effect

High Q value transducer, high ultrasonic conversion efficiency and long service life

Power intensity tuner to select suitable power output varies in different cleaning processes

Detailed Images

Circulating Filtration Cleaning Bath Ultrasonic Cleaner is applied for some specific cleaning purposes, we make ultrasonic cleaner with circulating filtration, during cleaning process, filtration system filters out contaminants, such as metal chips, fines, burned carbons and other particulate residues removed from materials to be cleaned, it is a circulation system, which keeps running throughout the cleaning process, in such ultrasonic cleaners, a filtration assembly is fitted, which comprises of filtration bath,motor pump and filters, there are many benefits of using filtration system with ultrasonic cleaning machine, first, it delivers most efficient cleaning as compared to basic ultrasonic cleaners, second, it extents life of cleaning agent or fluid and third is possibility of re-deposit of contaminants almost zero, in this way, ultrasonic cleaning machine with filtration system perfectly meets your requirements

Machine Uses

Circulating Filtration Cleaning Bath Ultrasonic Cleaner applies in industrial cleaning of auto parts such as engine parts, cylinder, carburetor, pistol, engine head, Fuel nozzle,engine block and other hardware, ultrasound wave agitation force can penetrate into the blind holes, cracks,crevices, corners, and any other hand-inaccessible area to dislodge the robust contamination, the built-in circulation filtration system integrates in the cleaning procedures

Via intermittently drain out the floating oil and resettled sludge, the whole cleaning procedures are accomplished in one machine

Illustration

Circulating Filtration Cleaning Bath Ultrasonic Cleaner is composed of ultrasonic generating system, vibration spectrum, liquid tank, filtering circulation system and controlling panel, all in one machine of compact structure used for small, medium volume industrial cleaning process, the completely circle integrates modular units of immersion, dislodging, stripping off, filtering, circulating, and draining out

Contact Us

Circulating Filtration Cleaning Bath Ultrasonic Cleaner is acceptable for bespoke constructions in functionality, dimension , processing procedures, keepleader has decades of experimental fabrication, our in-house technical support team can help our clients around the world with their individual cleaning processes,please don’t hesitate to contact us for further advice and assistance

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader