Rotary Hot Foil Stamping Jewelry Paper Box Bronzing Machine of Gift Packaging Cardboard Boxes Gold Silver Foil Blocking Printers

Rotary Hot Foil Stamping Jewelry Paper Box Bronzing Machine

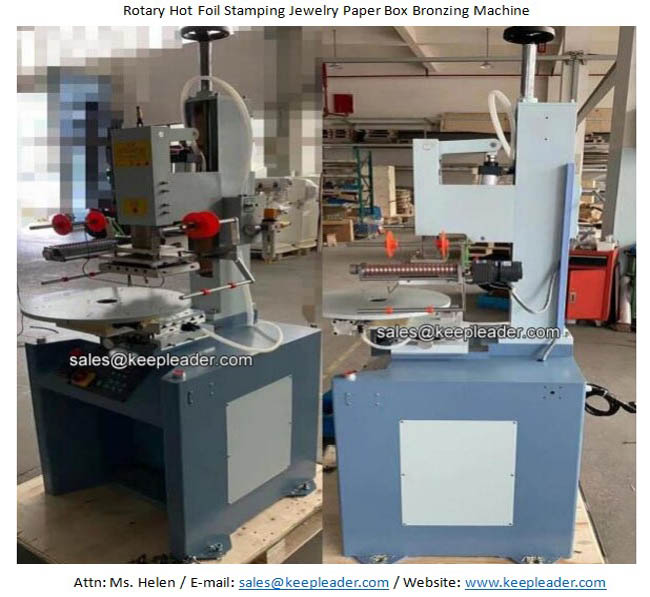

Rotary Hot Foil Stamping Jewelry Paper Box Bronzing Machine is constructed with customized configuration and dimension, is designed and manufactured by using of premium grade of raw materials and high technology, this hot foil stamping machine is capable for crisp imprinting onto the surface of box/container/case made of paper,plastic, leather,wood and any other harden packaging material, automatic turntable cam indexing integrates with auto robotic arm unloading device and paper feeding system to combine a semi-auto production in gift box packaging making, this hot foil stamping machine assures the customer of its quality and authenticity, Rotary Hot Foil Stamping Jewelry Paper Box Bronzing Machine can create a number of beautiful designs and graphic texts onto various materials, this machine is very cost effective and can be easily availed at reasonable prices

Machine Description

Rotary Hot Foil Stamping Jewelry Paper Box Bronzing Machine

01:Application

Rotary Hot Foil Stamping Jewelry Paper Box Bronzing Machine equips with auto pigment foil auto feeding device in roll, automatic turntable indexing of 6pcs working positions,auto robotic arm for unloading, and logo programmable Logic Control with touch screen, is used for golden bronzing Jewelry box in gift packaging making or any other harden case/box/container made of plastic, wooden, paper and leather, the parameter is adjustable in pressure, timer, counter, temperature, speed and depth to get the crisp printing, this hot foil stamping machine have optional colors with changeable pigment foils, servo motor controlled driving system is accessible via PLC programming technology, guiding system in operation assist on setting, restoration, maintenance and diagnosis

02:Parameter

Name | |

Model | KLS-8386ST |

Power Plug In | 220v,50hz or 110v, 60hz |

Power | 1000w |

Maximum Pressure | 0.8Mpa |

Motor Power | 750w |

Max Stamping Size | 100*100mm |

Heating Plate | 150*150mm |

Stroke Distance | 60mm |

Operation | Semi-Automatic |

Actuator | Pneumatic Stamp and Sevo Motor Controlled Unloading Device |

Working Station | 6pcs |

Control System | PLC Touch Screen |

Max Stamping Temp | 380 Degree |

Heating Element | 2pcs of each:600w |

Max Printing Speed | 1500pcs/Hour |

Dimension | 1500*1100*1800mm |

Weight | 380kgs |

03: Salient Characters

Full automatic pigment foil feeding in roll

Hand-wheel drives Vertical linear control the travel of working head

Auto cam Indexing unit for high precise robotic arm unloading device

Quick-changeable stamping die is mounted on the sliding back plate

Laminated heating plate, back plate and stamping die are separated

The sliding back plate mounted stamping die is adjustable in positioning

Adjustable worktable in multiple directions for quick concentric positioning

Programmable logo control with touch screen for visible operation and setting

With crank design of stamping to exert stable,sufficient and uniform pressure

Pressure,temperature, speed and time all are adjustable in stamping operation

Servo-motorized paper feeding mechanism to improve the productive efficiency

Intelligent digital temperature control, automatic constant temperature,uniform heating

Detailed Images

Rotary Hot Foil Stamping Jewelry Paper Box Bronzing Machine adopts pigment foil transfer imprinting that invoices transferring pre-dried inks or foil to the surface of material applying heat and a mold or die, the foil used in hot stamping application is often shiny and metallic, they mimic the look of precious metals such s copper, silver and gold, the person often see hot foil stamping on not only paper box in gift packages but also book cover, stationary, and other paper products where an element design is needed, however, hot foil stamping machine is suitable for imprinting on a variety of materials, such as paper, leather, fabric cloth, plastic and rubber,hot foil stamping allows you to mark or decorate an endless list of everyday products, you can easily stamp words, logos, and images on boxes, invitations, leather products, plastic/paper packaging ad much more

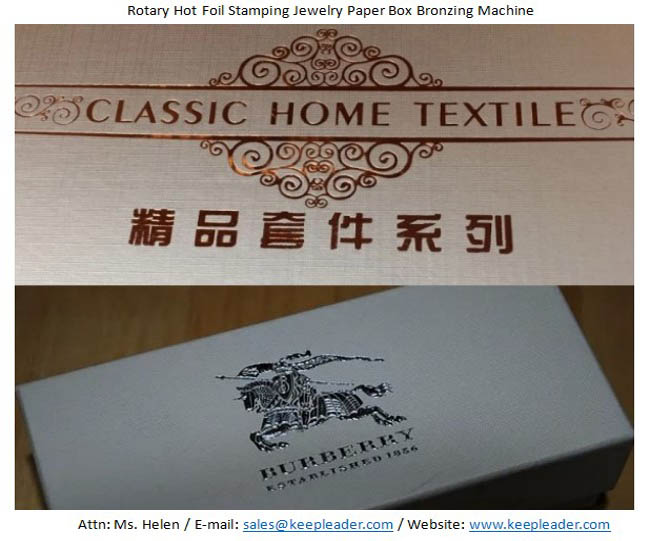

Machine Uses

Rotary Hot Foil Stamping Jewelry Paper Box Bronzing Machine will significantly improve the visual impact of jewelry box in gift packages making, the way to achieve embossing in golden or silver bronzing, the embossing process exerts stamping indents to form a colorful three-dimensional projection, the imprinted paper box will have metallic-looking signs/codes/logos/texts/graphic to catch the eye, moreover, the hot foils stamping also can improve the identification in marketing competitors

Contact Us

You can reply on our Rotary Hot Foil Stamping Jewelry Paper Box Bronzing Machine to handle your tasks with ease of paper box bronzing in gift packages making, our hot foil stamping machine is more compact, every-efficient and user-friendly compared to the competition, you don’t need any previous experience to product beautiful foil images or letters on your paper box, the visible menu controls allow you to easily adjust the temperature, timer, and other settings, thanks for our tech team, never halt our innovation, development upon its configuration in improving gratification, authenticity and efficiency at affordable price,believe that your can attain more from your consultation to our final cooperation

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader