Wiring Termination Welding Terminals Ultrasonic Welder for Copper Wire Terminals_Wires Harness_Cable Splicing Ultrasound Welders

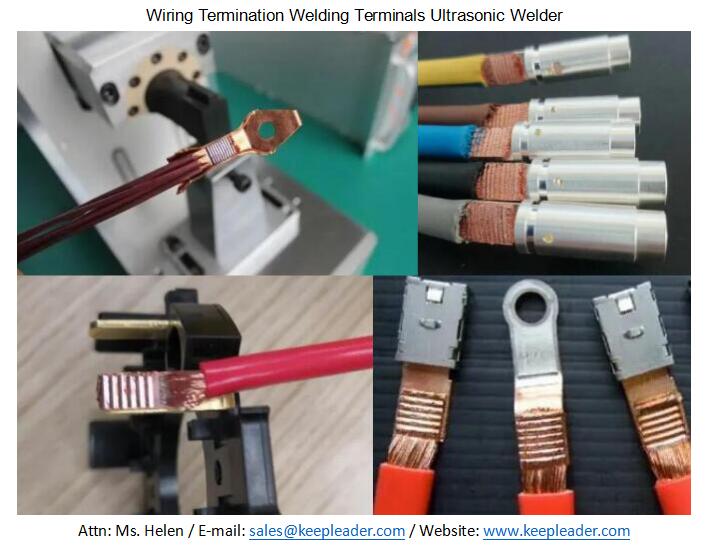

Wiring Termination Welding Terminals Ultrasonic Welder

Wiring Termination Welding Terminals Ultrasonic Welder adopts the solid-phase welding method, and the connection between the wire and termination is realized by the high frequency elastic vibration of the acoustic system and the static pressure between the wire and terminations, under the combined action of static pressure and elastic vibration energy, the wire and termination converts the elastic vibration energy into friction energy, deformation energy and thermal energy, thereby forming pure metal bonding and atomic diffusion on the surface of the two wire and termination

Machine Description

Wiring Termination Welding Terminals Ultrasonic Welder

01: Application

Wiring Termination Welding Terminals Ultrasonic Welder takes reliable bonding process in wire/cable splicing and terminal assembling, computerized ultrasonic generator provide operators with data control of storing, presetting, monitoring, detecting,maintaining and trouble-shooting, pneumatic or servo motor impels activity, ultrasonic sonotrode integrates wedge reed to avoid missed strands in holding pressure,Wiring Termination Welding Terminals Ultrasonic Welder attain increasing favors in wire,cable assembling in manufacturer of automobiles, motorcycles, electronics, motors, electrical appliances, solar energy, batteries, computers, communication equipment, instruments, hardware and other industries,Wiring Termination Welding Terminals Ultrasonic Welder sorts to mechanical process, no current flows through the work-piece, so the metal conductivity is not affected, the metal surface is generally attached with pollutants and oxide layer, the use of Wiring Termination Welding Terminals Ultrasonic Welder, without prior treatment of the bonding surface, ultrasonic vibration can directly crush the attachment after removal

02: Parameter

Description | |

Model | KLM-20HHZ |

Ultrasonic Frequency | 20KHZ |

Ultrasonic Power | 1000 thru 5000w |

Power Plug In | 110v,60hz or 220v, 50hz, Phase Voltage |

Contol Voltage | 24v |

Welding Area | 4~50mm2 |

Wire Material | Copper/Cu, Aluminum/Al, Tin Coated, Enamel Coated |

Welding Pressure | 0~0.9Mpa |

Stroke Distance | 30mm |

Welding force | 1200 Newton Max |

Weight | 80kgs |

Szie | 650*400*860mm |

03: Salient Characters

No Need any flux, fillers, solder, gas to assist on bonding

Ideal parameters reduce stress on wires increasing durability

Adopt a pure cylinder motion system, easy to use and operate

Software has English and Chinese version in one operation panel

Stable welding process, online inspection and control is acceptable

The welding material does not melt and is not fragile as a conductor

Scanning detection to monitor procedures in welding to ensure the yield

Fast welding speed, high welding strength and less energy consumption

Cold solidification without pollution,don’t need any other auxiliary equipment

Compact structure, robust construction to save the space with high longevity

Computerized power box integrates with pneumatic driven pressing system

Preventing empty welding to protect welding head in accident pressing down

Partial time in second to achieve quick bonding and lowest energy consumption

Welding without sparks, smoke, and dust, environmental protection and safety

Capability of over 20 weld steps with unique force and amplitude parameters

Energy and frequency remain constant to achieve equality in bonding effect

Programmable logic control with touch screen gains convenient access and precision control

Excellent electrical conductivity after welding, high strength, extremely low or almost zero resistance

Ability to change and adjust force and amplitude during the weld cycle to optimize welding data for each specified wire application

Numerically controlling software to store, preset parameters for bonding versatile sized wire, additional support parameter numerically tuning

Detailed Images

Wiring Termination Welding Terminals Ultrasonic Welder attains market recognition that has the vitality for long-term sustainable development, keepleader, we adheres to the customer first priority principle of cooperation, to provide customers with timely pre-sale and after sale service and technical support, we have introduced a large number of modern high-quality management personnel, and together we have built a scientific and complete modern management system, keepleader serves customers with high-standard and strict production management and logistics management, and has successively passed a number of quality certifications

Machine Uses

Our Experts develop the perfect Wiring Termination Welding Terminals Ultrasonic Welder Solution for your application of wire/cable assembling, this will optimize your production with a safe joining process in combination with durable welding tools that are 100% make in our working shop, you toll can benefit from the advantages of Wiring Termination Welding Terminals Ultrasonic Welder that taking out salient prominence including high strength, no losses in conductivity, short cycle time, particularly gentle on materials, low energy consumption, permanent process monitoring

Contact Us

Keepleader, we are always interested in trying new application as Wiring Termination Welding Terminals Ultrasonic Welder has endless possibilities, contact us today to learn more and inquire about our free sample testing prior to your purchasing, believe that our engineer can work out a reliable solution for you with flexible productive tooling kits

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader