Ultra Sonic Welder Ultrasonic Plastic Welding Machine for PP_PVC_PE_PS_PC_ABS_Acrylic Sealing 20khz Ultrasound Bonding Equipment

Ultra Sonic Welder Ultrasonic Plastic Welding Machine

Ultra Sonic Welder Ultrasonic Plastic Welding Machine works in principle of inducing ultrasonic frequency in thermoplastic components boning that is converted into heat between the welded plastic laminates, frictional heat is produced and dispense at the energy director built in the connecting joints, because of low heat conduction in thermoplastic, under the controlled pressure applied, the insoluble sealing is happen, the connection is forged in a very short period of time, the melting point of both working pieces is nearly equivalent which helps to form an uniform weld area, the welded area is usually as strong as the matrix material

Machine Description

Ultra Sonic Welder Ultrasonic Plastic Welding Machine

Name | ||

Model | KLC-2020 | KLC-3220 |

Ultrasonic power | 2000w | 3200w |

Ultrasonic frequency | 20khz | 20khz |

Travelling Depth | 70mm | 70mm |

Welding time | 0.1~99s | 0.1~99s |

Air Compressor | 2HP | 2HP |

Pressure Applied | 2~7 Bar | 2~7 Bar |

Vibration system | Auto-stimulating | Auto-stimulating |

Welding size | 180mm | 200mm |

Power Supply | 220V/50hz | 220V/50hz |

Net weight | 160kgs | 180kgs |

02: Application

Ultrasonic welding of thermoplastic materials creates a molecular bond within the welding seam, longitudinal vibrations in frequencies of 15khz, 20khz and 35khz with tool amplitudes between 5um and 50um are introduced into the plastic materials under the action of force, ultrasonic vibrations are focused by means of special design of components of tools, this specific geometry within a component is referred to as energy director, the contact points in the joining area actively molded by means of energy input to achieve elastic deformation occurring between the contact surfaces and within the molecule chains generates heat that causes the materials to melt

03: Highlighting

High efficiency converter

Rigid frame construction

Pneumatic speed regulation

Frequency tuning with reading of idling and welding power on the instrument

Triple time for delay time, welding time and holding time

Welding pressure adjustable for 6 bar

Palm button or foot operated switch operation

Microprocessor based controller

Welding time, holding time settable in the steps of 100 milliseconds

Digital counter up to 100,000 counts-reset-table

Digital bar graph to indicate tuning and energy during the welding cycle

Leveling screws provided on the ultrasonic assembly for each leveling and alignment

Of horn face with the welding object

Detailed Images

Ultra Sonic Welder Ultrasonic Plastic Welding Machine has 15khz and 20khz, but, for 20khz, its maximum power is 3200w, semi-crystalline material need strong ultrasonic energy in its bonding,15khz welder has maximum power 5200w, So, 15khz is usually proposed for big size of semi-crystalline material, keepleader has versatile models for option,such as table-top type, free-standing type, auto rotation indexing and horizontal, vertical type, in addition, we also can built integration of robotic arm for automatic loading and unloading, mount sound-proof cabin to reduce the ultrasonic sound in establishing cosy,clear and safe working environment

Machine Uses

Ultra Sonic Welder Ultrasonic Plastic Welding Machine exerts hermetic sealing of thermoplastic, such as PVC, PS,PE,PP,PC,ABS, Acrylic,PET, HDPE,Nylon Fabric in field of automotive, electronics, home appliances, industrial components, electrical components, lighter, toys, gadgets, medical, personal appliances and more

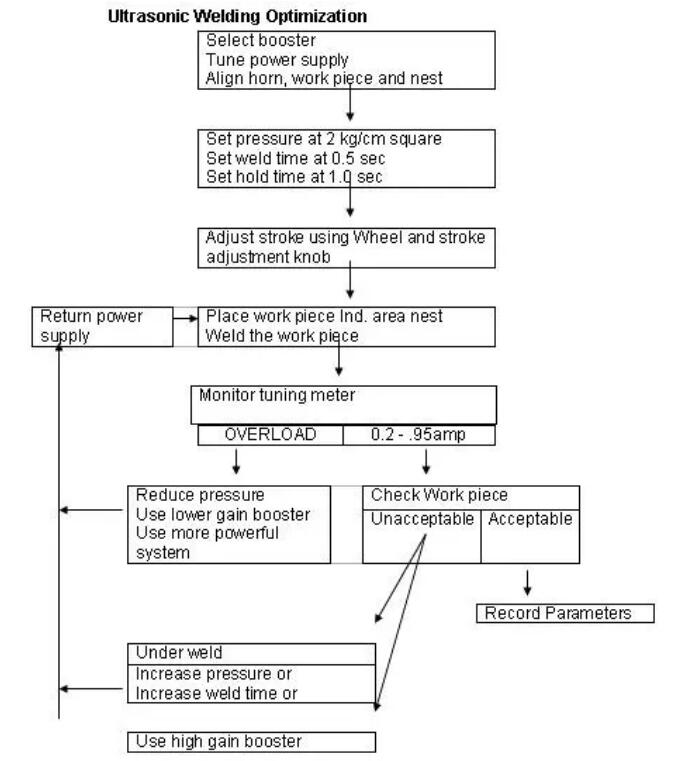

Production Flow

Ultra Sonic Welder Ultrasonic Plastic Welding Machine stands out of its competitors for instant, efficient, reliability and repeatability, the welding process is simple and yields high productivity, ultrasonic plastic welding machine reduces labor cost, improve the working efficiency, save the consumption without using any fasteners, adhesive,nail, and filling material and yields cleaner looking assembles with marvelous aesthetic appearance

Contact Us

Ultra Sonic Welder Ultrasonic Plastic Welding Machine is suitable for welding operation of thermoplastic parts from medium to large size, this technique is fast, efficient, non-contaminating and requires no consumables, in addition to welding,ultrasonic processes can be used to insert, stake,embed,laminate thermoplastic films and fabric,spot welding, swage, degate and hermetic sealing,one ultrasonic welding machine combine specific acoustic tool and holding fixture can accomplish all of these application, just present sample picture of your processing object with necessary gauged dimension for tech verification prior to recommendation

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader