Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer of Electric Wires_Cables Rubber Marking_Coding_Foil Printing Coder

Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer

Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer is available in three configuration, manual lever, pneumatic, motor actuation to meet both your application requirements as well as your budget, pneumatic and motorized models can be easily interfaced with wire processing machines and their small footprint makes them an easily integrated into existing production lines,the quantities of character discs and font sizes are freely-selection, the users have the ability to make a wide range of material including cable and wire, heat-shrink sleeve and plastic tube

Machine Description

Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer

01: Application

Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer is an electric pneumatic thermal stamping device use for imprint cables, wires and flat stock, the hot stamping process employed by this device produces high quality, abrasive resistant markings, the material to be imprinted is pressed against a pigment foil and heated stamping type faces, all stamping parameters such as pressure, dwell and temperature are freely select-able in adaptable to the application concerned, a foot pedal actuation allows you to hold cable with both hand, wire straightener, foil rewinding system and wheel lock and add-on allowing for large series production

02: Parameter

Title | Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer |

Model | KLS-1240D |

Power Plug In | 220v, 50hz, 500w |

Qty of Type-wheel | 24 |

Qty of Characters per wheel | 40 |

Character Size | 2.3*2.3mm or specified dimension |

Adaptable Diameters | 1.5 through 15mm |

Signs in Each of Type-wheel | 0 through 9, A Through Z,./ and Blank |

Driven System | Pneumatic or Manual Lever and Motorized Driven |

Pigment Foil Color | White, Black (Other Colors upon request) |

Foil Usage Per Mark | 3mm adjustable |

Material of Type-wheel | Copper |

Triggering Control | Pedal Value |

Max Melting Depth | 0.76mm |

Front Face | Concave or flat |

Qty of printing Tower | 2 or integrated into 1 |

Printing Tower Interval | 130mm or bigger |

Heating Temperature | 100~180 Celsius Degree |

Marking Pressure | 0 through 6 bar |

Character Size | 1.0 through 3.5mm |

Stamping Pressure, Time | Adjustable |

Characters Combined | Freely-selection via rotary character discs |

Packaging Volume | 0.38CBM |

Volumetric Weight | 60kgs |

CE Compliance | Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer complies with CE and EMC Equipment guidelines relative mechanical and electric safety and electromagnetic compliance |

Important Note | KEEPLEADER recommends that samples be submitted in cases where there is doubt as to the processing capabilities of particular Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer |

03: Salient Characters

Solid state dwell timer for better repeatability

Prints in-line with most major wire processors

Prints horizontally or vertically along the wire

Utilizes full-size, 40 character type-wheels/discs

Large selection of character sizes and foils

Closed loop integral temperature controller

Less operator fatigue than a lever operated machine

Can be easily interfaced with wire processing machines

Foil cartridge allow quick foil changeover and alignment tuning

Prints on command from wire processor, cutter, stripper or terminator

Stroke adjustment to ensure maximum production rate based on wire size

Available for insulated wire and cables with connectors or terminated ends

For hot stamping cable and wire insulation, heat shrink sleeve and plastic tubing

Quick-change fixture system minimizes set-up time and maximize printing speed

Standard V- wire-guiding block to allows marking on cable up to 15mm outer diameter

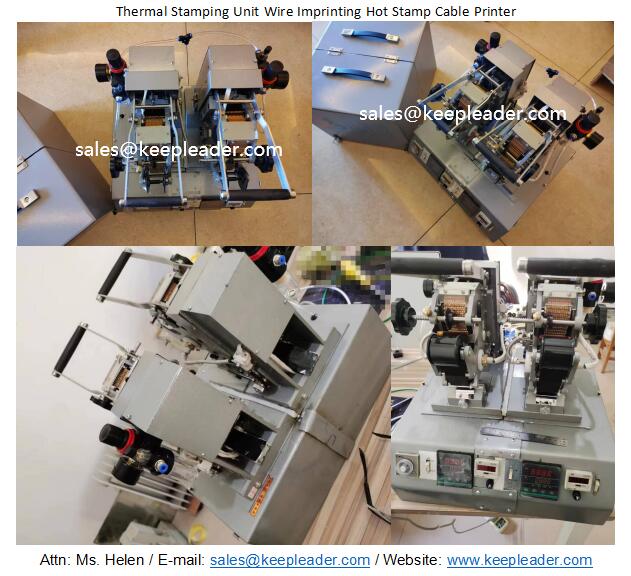

Detailed Images

Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer is compacted table-top hot stamp wire imprinting unit, that accommodates wire sizes from 1.5~15mm in diameter, loading position of side and front access both are available to complete marking horizontally or vertically along insulated wire or cable including PVC, Teflon and other materials, utilizing specified quantities of full-size 40-character type-wheels, semi-automatic features foot pedal activation and intermittent motion, it is suitable for automotive, motorcycle and aviation cable or wires as well as products such as fishing line

Machine Uses

Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer has compact and robust construction that is pedal valve activated using for heat-shrink Sleeve, Industrial wire assembling, Cables,Plastic tubing, fishing line and other plastic strip, long-lasting markings obtainable with simple operation, identification solution for a variety of application including electrical cable, control cables, cable ties and molded parts, easy-dial type-wheels or individual type and blocks to accomplish various cods marking

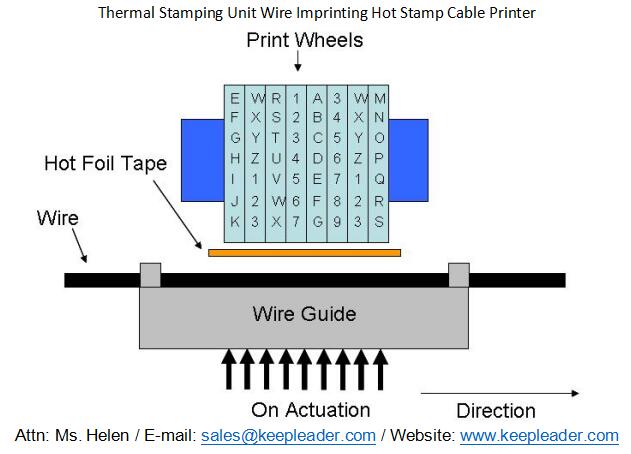

Functional Illustration

Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer is designed for the economical and high quality marking of wires, cables, shrink sleeve,plastic tubing even for fishing line in wire assembling of aviation, motorcycle and automotive. The combination of characters and character size can be selected freely within the specific range, the hot stamping marks process is suitable for making thermoplastic materials, during the process the preheated character wheels imprint the precision-engraved characters by pressing the pigmented marking foil into the selected material, the concave from of character is exactly matched to the diameter of the processed material, the precise adjusting options for the stamping pressure, time and marking temperature allow to recall every result

Contact Us

Are you ready to maximize downtime,contact our technique team today, we’ll assist on determine the best Thermal Stamping Unit Wire Imprinting Hot Stamp Cable Printer for your production line

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader